Sealed fire insulation escape cabin door for ship

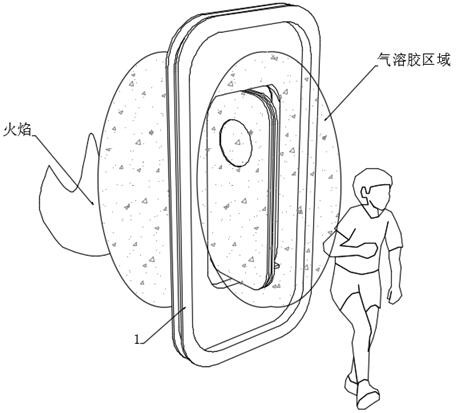

A fire isolation and cabin door technology, applied in the field of cabin doors, can solve problems such as no escape device, trapped persons unable to escape in time, fire, etc., to prevent internal flame deflagration, avoid fire spread, and reduce influx effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

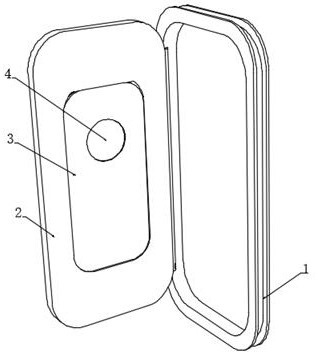

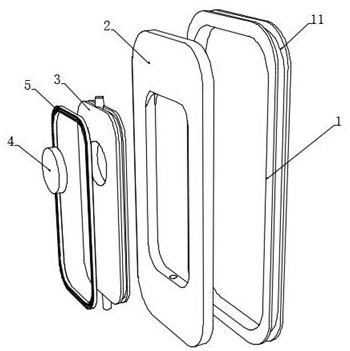

[0046] see Figure 1-7 , a sealed fire-proof escape hatch for ships, comprising a door frame 1, a door body 2 is rotatably connected to the side wall of the door frame 1, an escape revolving door 3 is arranged in the middle of the door body 2, and the upper and lower ends of the escape revolving door 3 pass through a rotating shaft 31 is rotatably connected to the door body 2. The front and rear walls of the door body 2 are embedded with a temperature sensing column 6. The temperature sensing column 6 includes an external temperature conduction shell, and the left end of the temperature conduction shell is connected with a piezoelectric ceramic through a hot melt rope 63. 61. A magnetic impact block 62 is also connected to the inner right end of the temperature-conducting shell through a hot-melt rope 63. A separation ring 64 is arranged in the middle of the temperature-conducting shell. The separation ring 64 is made of magnetic material. There are liquid storage chambers 22 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com