Processing equipment and production process for PPTC (Polymeric Positive Temperature Coefficient) protector for power type battery

A processing equipment and protector technology, applied in the field of PPTC protector processing equipment and production technology, can solve the problems of poor welding effect, workpiece falling off, separation, rapid heat loss, etc., achieve good heating effect and improve welding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

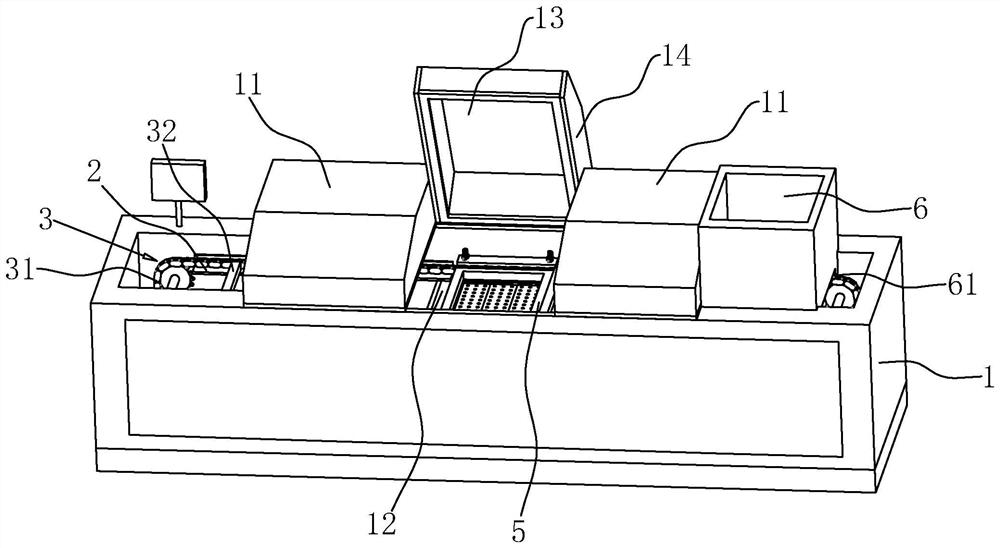

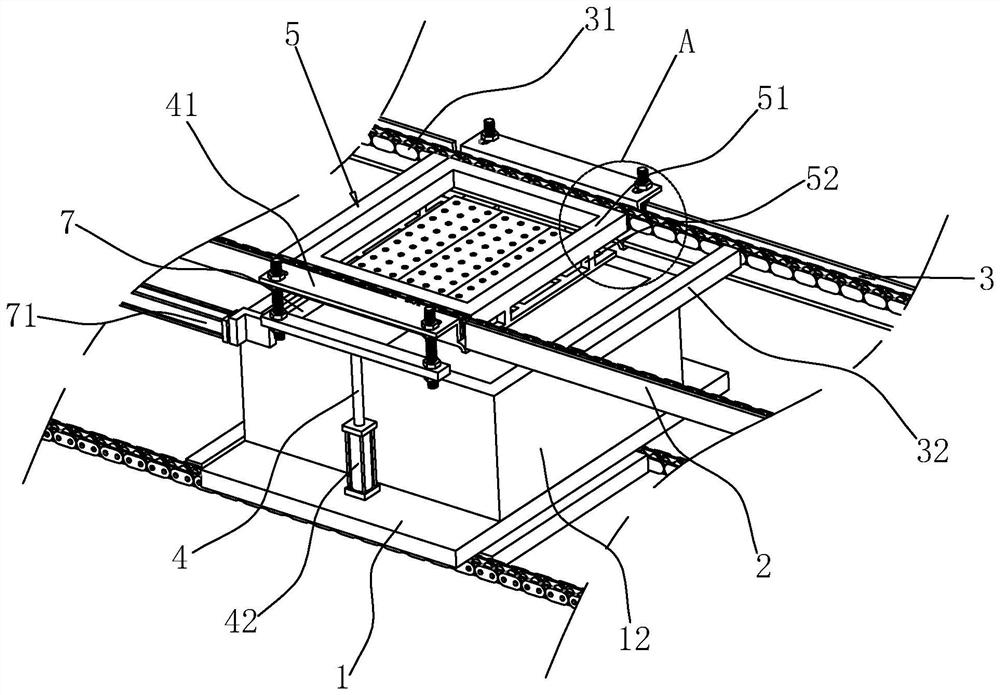

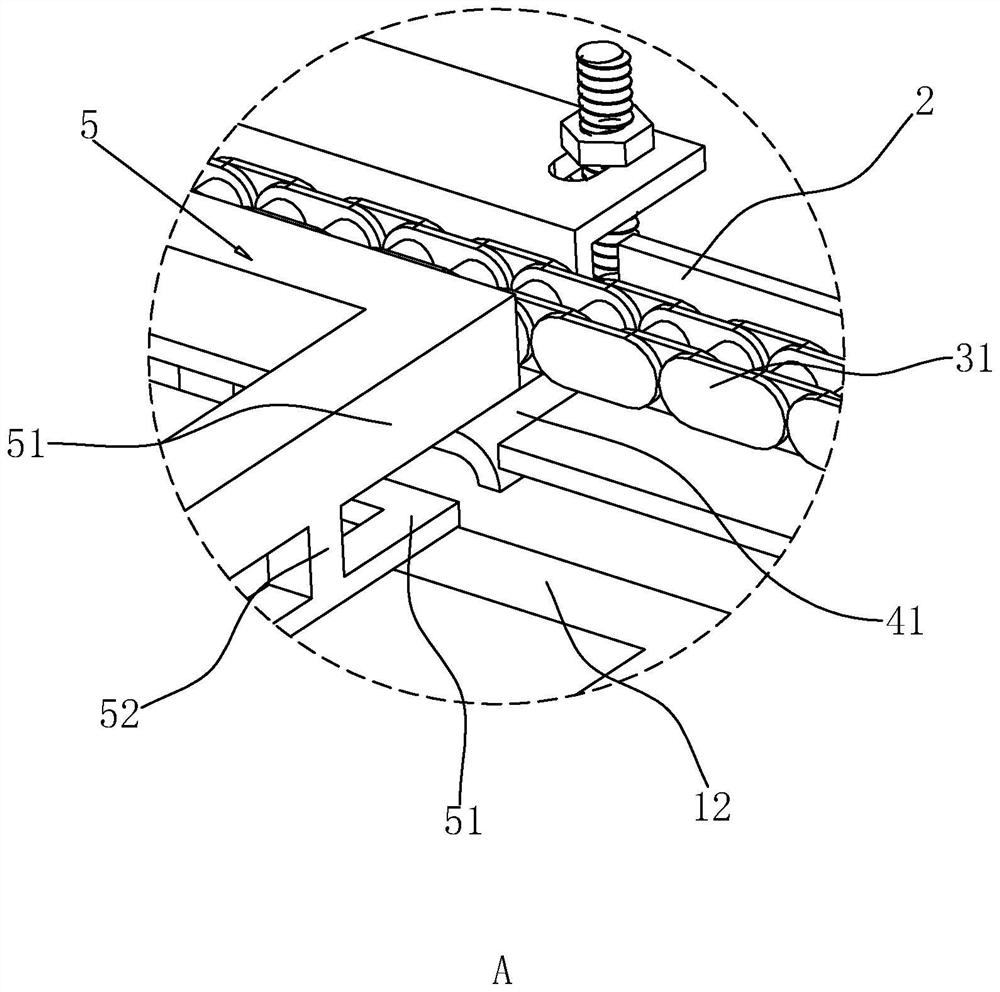

[0044] refer to figure 1, a PPTC protector processing equipment for power type batteries, including a casing 1, the casing 1 has a strong thermal insulation capability, so that the casing 1 has less heat exchange inside and outside. Two reflow soldering sections 11 are installed in the casing 1, and a solder dip box 12 is installed between the two reflow soldering sections 11. One end of the casing 1 in the length direction is set as the feeding end, and the other end is set as the discharging end; The casing 1 is installed with a driving member 3, and the driving member 3 drives the workpiece to enter the casing 1 from the feeding end, and then passes through the first reflow soldering section 11, the dip soldering box 12, and the other reflow soldering section 11, and then leaves the casing 1, and the completion is completed. Heat welding.

[0045] refer to figure 1 and figure 2 , Since the workpiece is small, the user needs to place the workpiece to be welded in the cor...

Embodiment 2

[0061] refer to Figure 4 The main difference between this embodiment and Embodiment 1 is that the lower end of the casing 1 is rotatably connected with a rotating shaft 8, the casing 1 is fixedly installed with a second motor, and the output shaft of the second motor is coaxial with the rotating shaft 8 Fixed connection, the second motor is in the starting state during processing, and drives the rotating shaft 8 to rotate. Two cams 81 are fixedly installed on the rotating shaft 8 . The two cams 81 correspond to the positions of the two lifting rods 4 one-to-one. When the cam 81 rotates to contact the lift rod 4 where the radial diameter is smaller, it drives the tooling frame 5 to descend into the dip soldering box 12;

[0062] The embodiment of the present application also discloses a production process of the PPTC protector.

[0063] refer to Figure 5 , a production process of a PPTC protector, comprising the following steps:

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap