Supercritical fluid assisted rapid foaming equipment for plastics

A technology of supercritical fluid and foaming equipment, applied in the field of foaming equipment, can solve the problems of different foaming rate and time, uneven heating rate of samples, poor crushing and processing effect, etc., so as to save foaming time and improve uniformity. And the effect of speed and improving heating uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

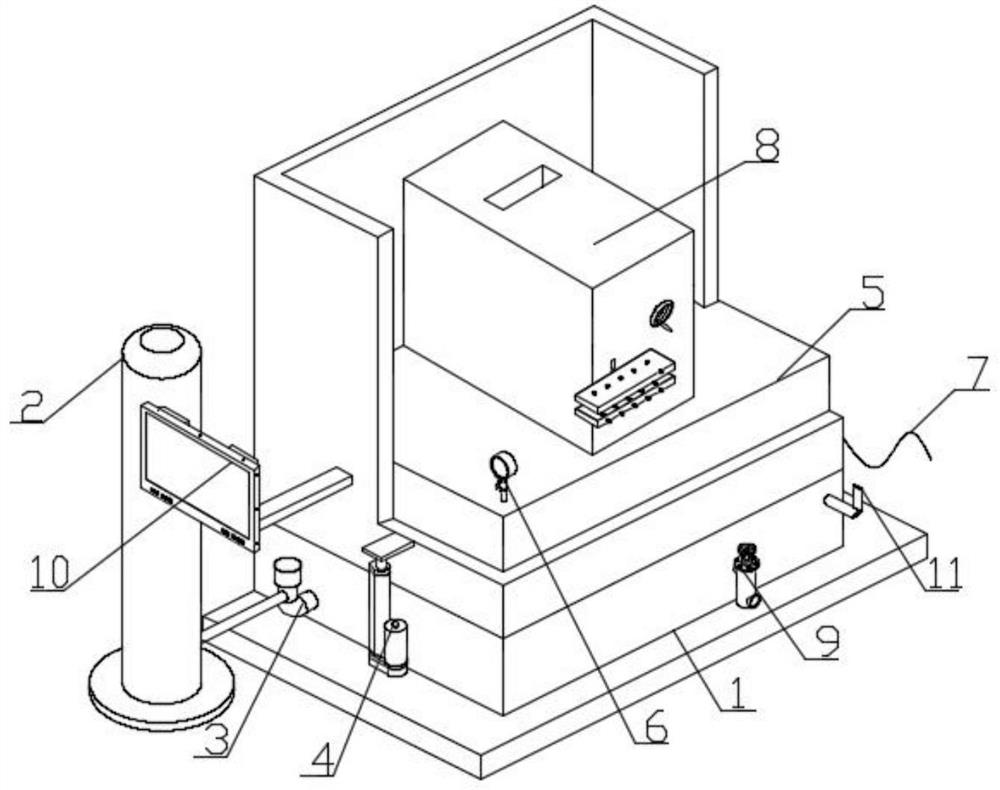

[0032] see figure 1 , a kind of supercritical fluid-assisted rapid foaming equipment for plastics of the present invention, a lower mold 1, the left end of the lower mold 1 communicates with the gas source tank 2 through a transmission pipe 3, and is arranged on the upper mold 5 at the left and right ends of the lower mold 1 And the hydraulic cylinder 4 can be used to control the upper mold 5 to move up and down, and the cooling channel pipe 11 used to receive the external cooling air source, and the cooling channel pipe 11 is arranged around the interior of the lower mold 1, and the top of the upper mold 5 is provided with a pressure for monitoring the air pressure. Table 6. The upper mold 5 is provided with a power cord 7 at the rear end, the lower mold 1 is provided with a pressure relief valve 9 at the front end, and a controller 10 is installed on the left end of the upper mold 5. The lower mold 1 and the upper mold 5 are provided with heating Thermocouple for air in inte...

Embodiment 2

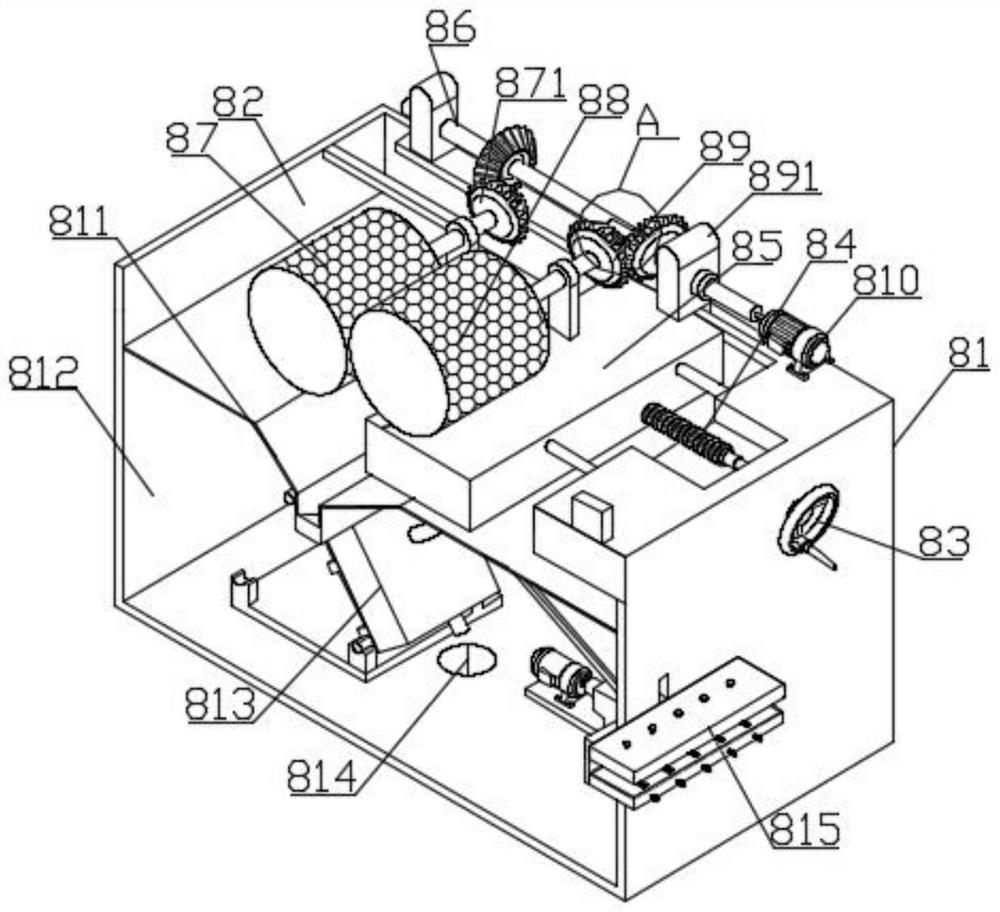

[0037] In a supercritical fluid-assisted rapid foaming device for plastics of the present invention, the lower frame 81510 matches the inner space of the upper frame 8157, and the upper frame 8157 is provided with multiple groups of conveying pipes 8159.

[0038] The present invention provides a supercritical fluid-assisted rapid foaming device for plastics through improvement, and its working principle is as follows;

[0039] First, when using the device, first place the device in the working area, and then connect the device to an external power supply, which can provide the required power for the device to work;

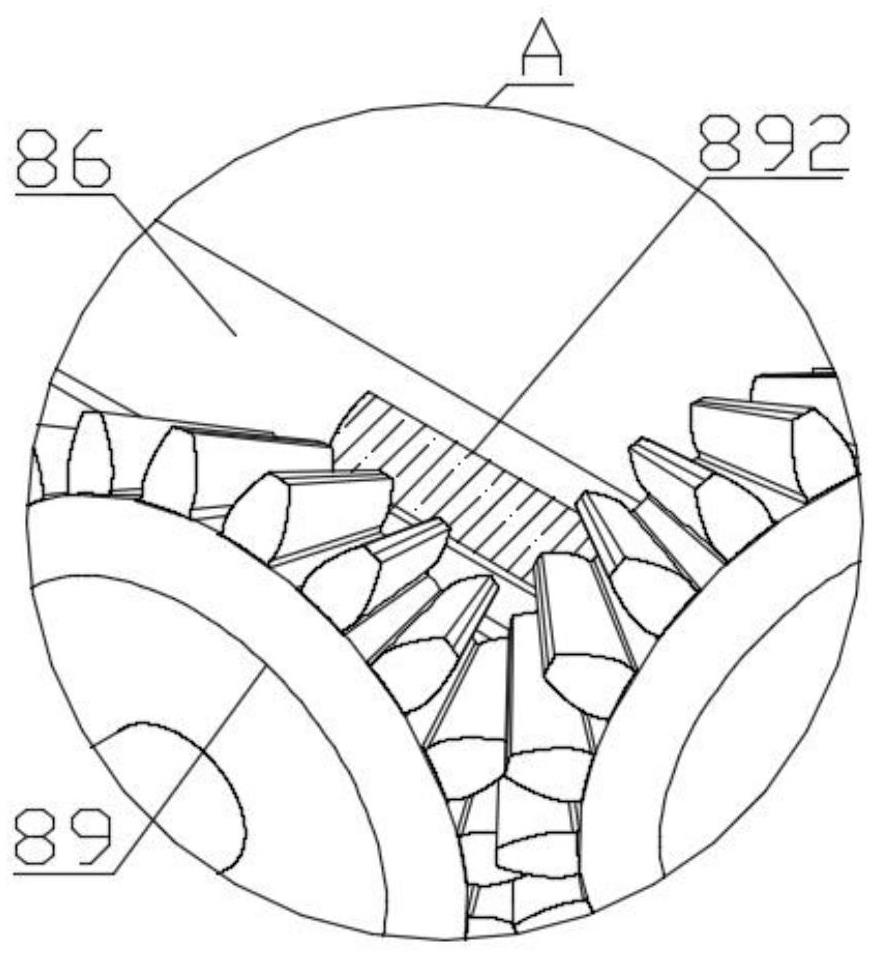

[0040] Second, when foaming the plastic, the sample can be placed in the first processing cavity 82 inside the casing 81, dropped to the middle of the left crushing wheel 87 and the right crushing wheel 88, and the output motor 810 can be started to apply power to drive The guide roller 86 rotates. During the rotation of the guide roller 86, it can drive the left ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com