Waste salt snow melting belt

A technology for melting snow and snow water, applied in other chemical processes, synthetic resin layered products, chemical instruments and methods, etc., can solve the problem of large processing solution, and achieve low manufacturing and use costs, high efficiency, and reduced use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

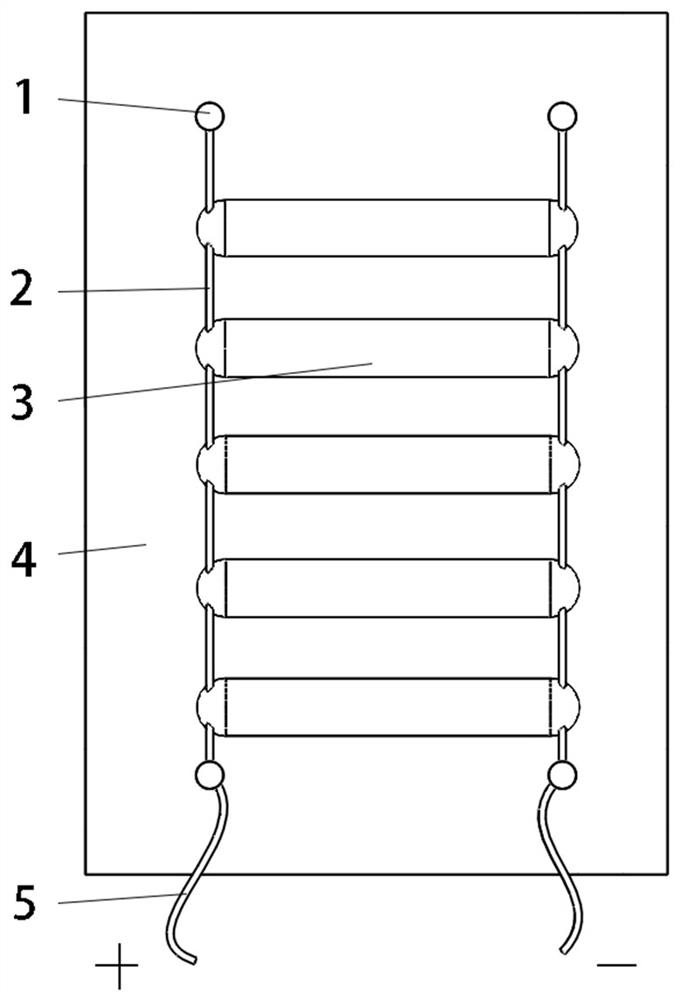

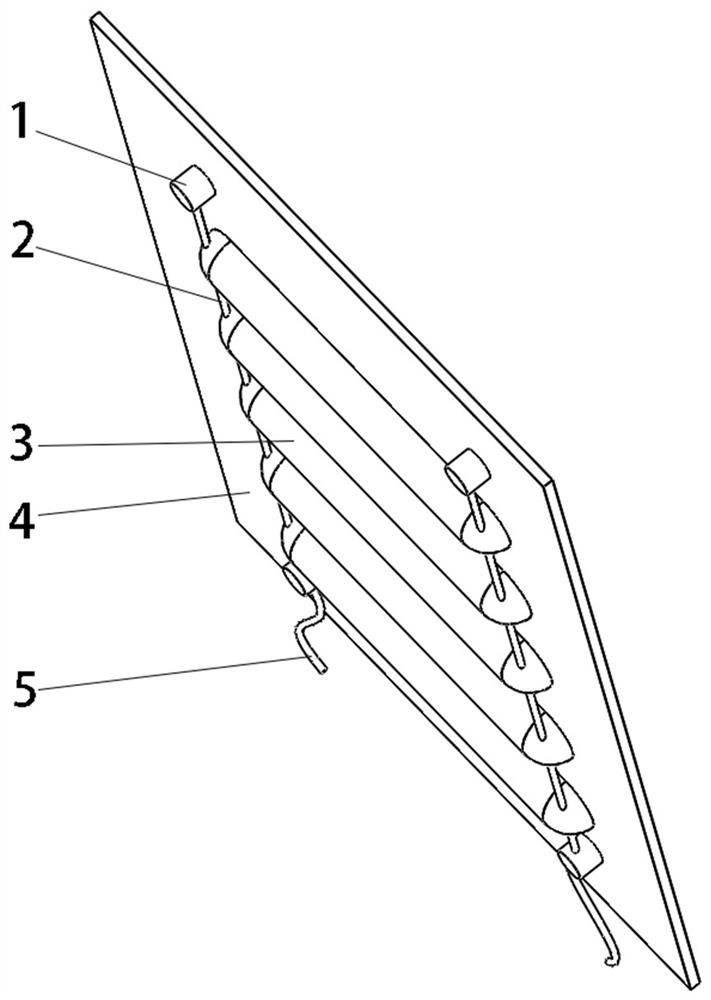

[0028] like figure 1 , 2 The shown waste salt snow melting belt is made of a one-way water-permeable double-layer membrane 4 material, and the double-layer membrane 4 material is sandwiched with 5 long strip channels 3 arranged separately, and the channels 3 are pre-loaded with waste chlorine. The powder of sodium chloride; the two ends of each channel 3 are respectively in contact with a copper wire 2, and the copper wire 2 is exposed in the channel 3, so that it can form an electrical connection with the electrolyte in the channel 3; both ends of each conductive wire Connect the electrode joints 1 respectively, and connect to the external power supply through the power cord 5 .

[0029] Then, cover the snow-melting belt to the road surface that needs to be melted, and collapse part of the snow by its own weight, so that a small amount of snow melts; Salt powder melts into electrolyte; electrification makes the electrolyte heat up, the snow heats up and melts into water flo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com