Novel high-thermal-conductivity die-casting aluminum alloy and preparation method thereof

A technology of casting aluminum alloy and high thermal conductivity is applied in the field of new high thermal conductivity die-casting aluminum alloy for heat dissipation shell of high heat dissipation devices and its preparation field, which can solve the problems of increasing alloy cost, difficulty in guaranteeing alloy fluidity, and high equipment requirements, and achieving reduction of Small lattice distortion, good tensile strength, good alloy fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

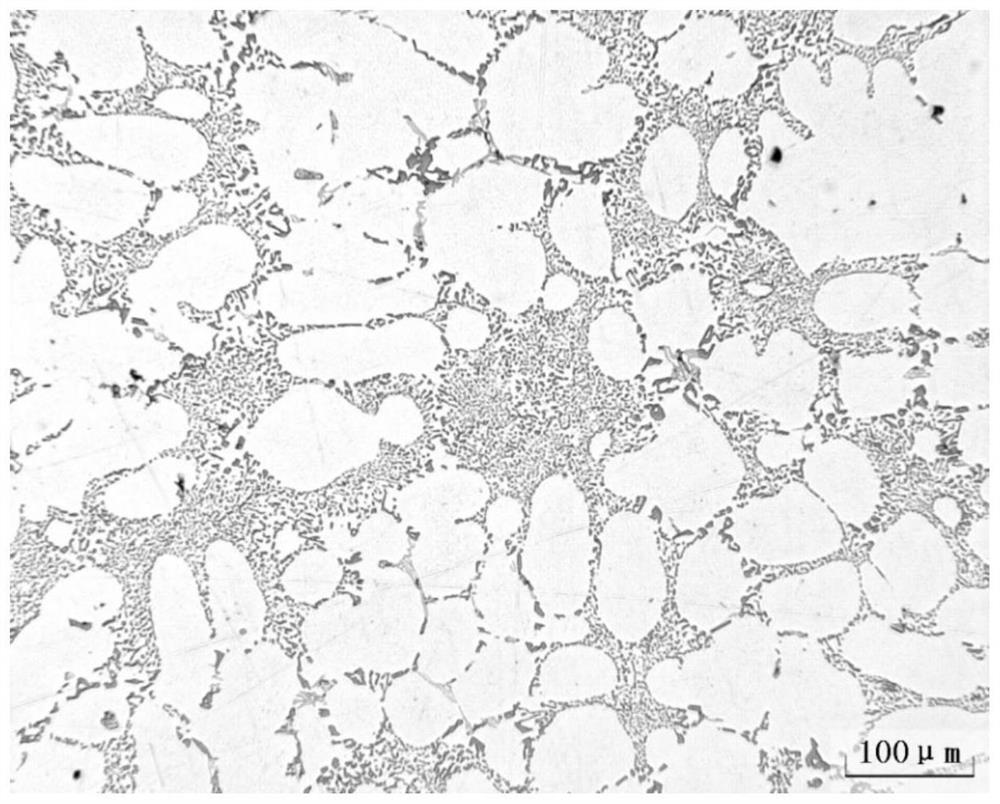

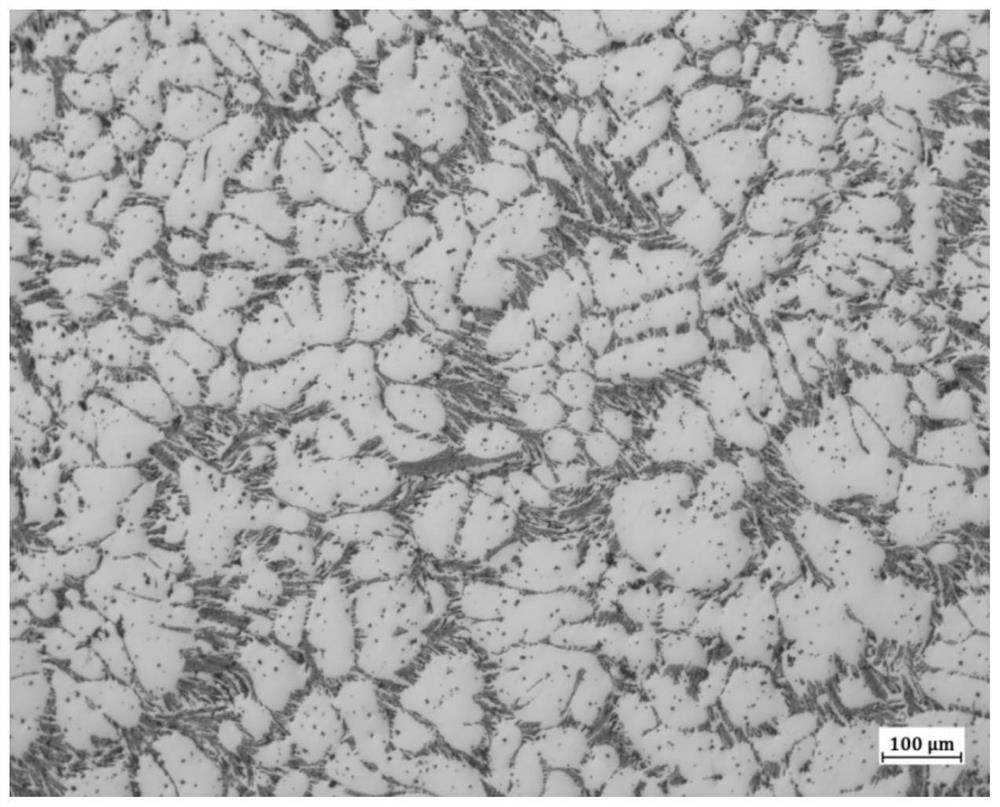

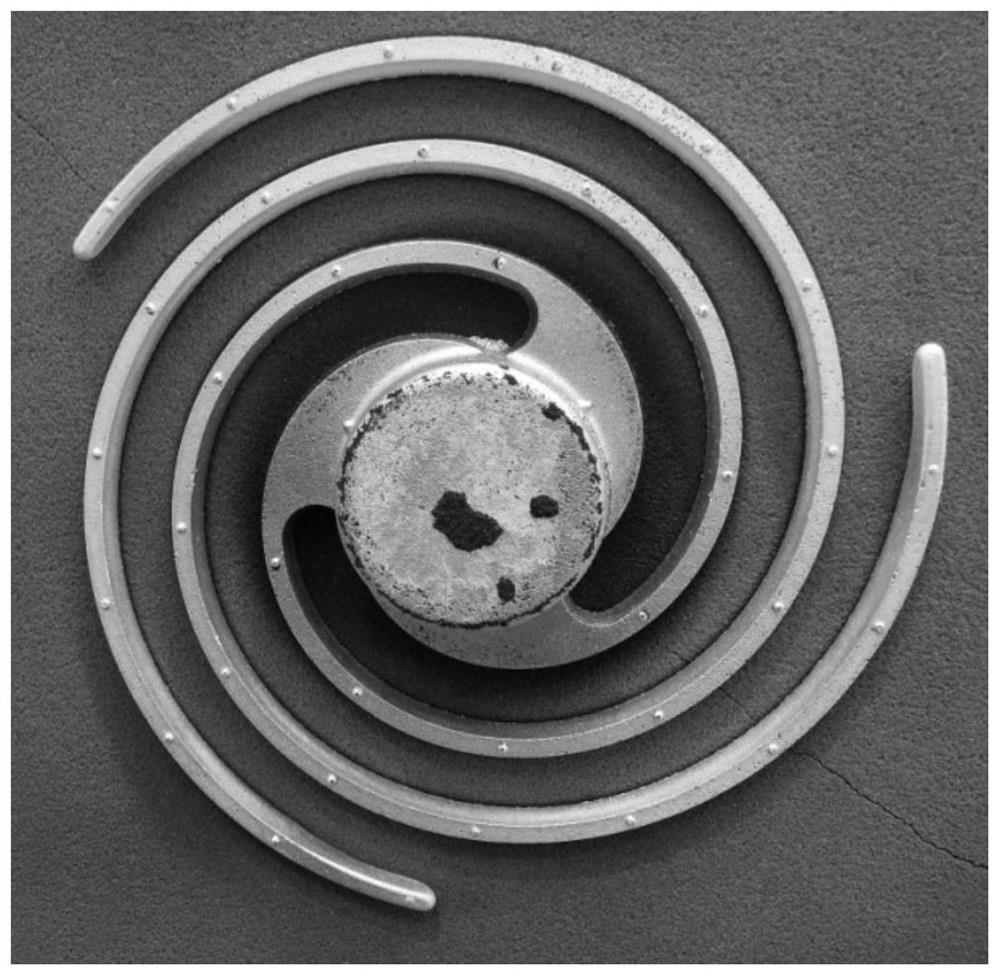

[0028] like Figure 2 to Figure 5 As shown, it is the first preferred embodiment of the present invention.

[0029] The new high thermal conductivity die-casting aluminum alloy in this embodiment is AlNi2Fe0.5B0.1Mg0.7Zn1.26, and the die-casting aluminum alloy includes the following components in terms of mass percentage: Ni: 2%, Fe: 0.5%, Mg: 0.7% , Zn: 1.26%, B: 0.1%, and the balance is Al.

[0030] The preparation method of the above-mentioned novel high thermal conductivity die-casting aluminum alloy comprises the following steps:

[0031] 1) Batching: according to the above-mentioned components and contents, batching is carried out;

[0032]2) Smelting: According to the above ingredients, firstly, pure aluminum, aluminum-nickel master alloy and aluminum-iron master alloy are added to the melting furnace for melting, and the temperature after melting is 700 ° C, and then pure magnesium, pure zinc and aluminum-boron master alloy are added for melting. , the temperature a...

Embodiment 2

[0038] The difference between this embodiment and the above-mentioned Embodiment 1 is only that the content of B in the new high thermal conductivity die-casting aluminum alloy is different. Specifically, the new high thermal conductivity die-casting aluminum alloy is AlNi2Fe0.5B0.2Mg0.7Zn1.26. In terms of mass percentage, the alloy includes the following components: Ni: 2%, Fe: 0.5%, Mg: 0.7%, Zn: 1.26%, B: 0.2%, and the balance is Al. The density equivalent value of the aluminum alloy solution is 0.2DI%.

Embodiment 3

[0040] The difference between this embodiment and the above-mentioned Embodiment 1 is only that the content of B in the new high thermal conductivity die-casting aluminum alloy is different. Specifically, the new high thermal conductivity die-casting aluminum alloy is AlNi2Fe0.5B0.3Mg0.7Zn1.26. In terms of mass percentage, the alloy includes the following components: Ni: 2%, Fe: 0.5%, Mg: 0.7%, Zn: 1.26%, B: 0.3%, and the balance is Al. The density equivalent value of the aluminum alloy solution is 0.3DI%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com