Thermal power generation boiler main steam temperature control system based on hybrid intelligent optimization algorithm

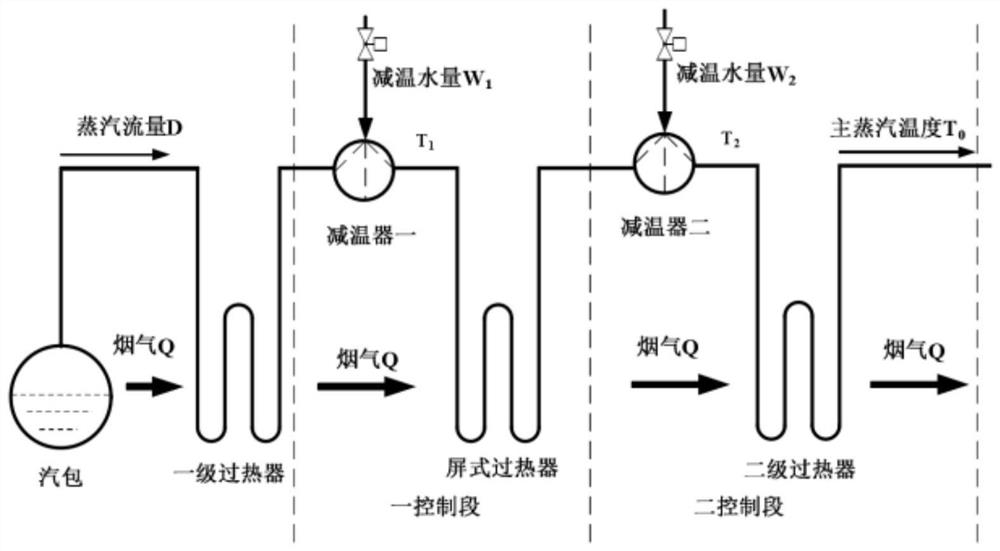

An intelligent optimization algorithm and technology of control system, applied in control system, steam generation, biological neural network model, etc., can solve the problem of large temperature fluctuation of main steam, increased labor intensity of operators, inability to adapt to variable parameters of main steam temperature control system, etc. Problems such as large inertia and large time delay

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

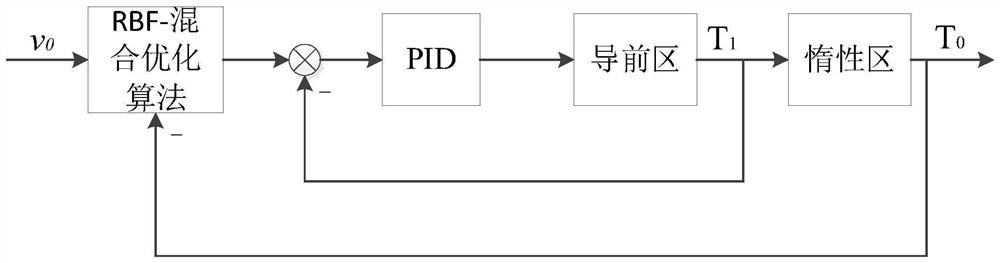

[0027] The main steam temperature control system of the thermal power boiler based on the hybrid intelligent optimization algorithm of the present invention is mainly divided into the following steps:

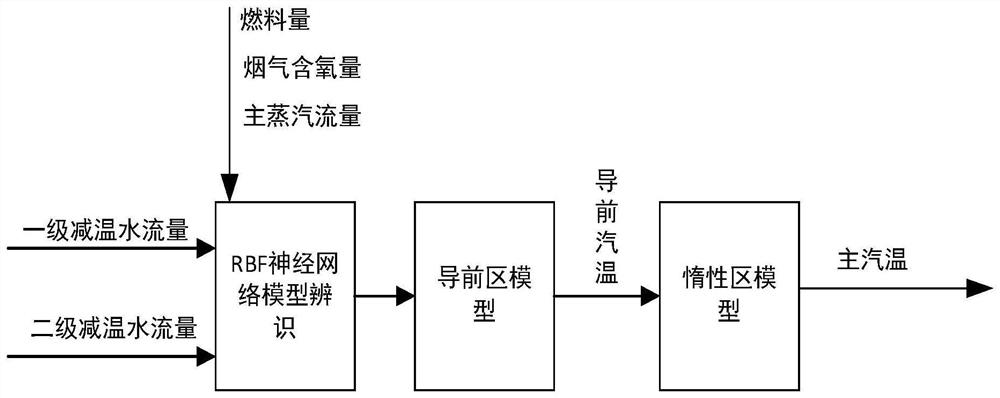

[0028] 1) RBF network model construction

[0029] Set the RBF network model input as: flue gas heat, main steam flow, desuperheating water flow. However, in the actual simulation process, since the heat of the flue gas cannot be measured directly, this paper uses the two variables of fuel amount and oxygen content of the flue gas to indirectly replace the heat of the flue gas as the input variable; Desuperheating water flow and secondary desuperheating water flow. Therefore, the input parameters of the RBF network model are: fuel volume, flue gas oxygen content, main steam flow, primary desuperheating water flow, secondary desuperheating water flow, among which the control variable desuperheating water flow, disturbance variables are the main steam flow, fuel volume, Oxygen c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com