Method for testing minimum ignition temperature of dust cloud in inert atmosphere

A technology of ignition temperature and inert atmosphere, applied in measurement devices, material thermal analysis, instruments, etc., can solve the problems of dust cloud combustion and explosion, casualties, property losses, etc., to achieve stable device operation, avoid risks, and improve economic benefits. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

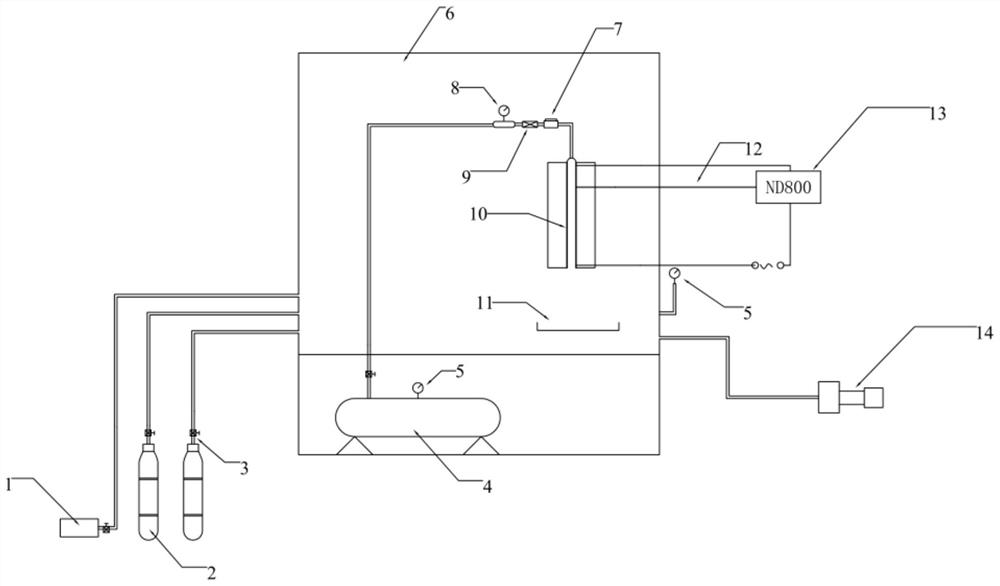

[0014] The invention provides a method for testing the lowest ignition temperature of dust clouds in an inert atmosphere, which is used to test the lowest ignition temperature of dust clouds in an inert atmosphere through the combination of a dust cloud lowest ignition temperature testing device and an atmosphere inerting device. The dust cloud minimum ignition temperature test device includes a tubular heating furnace, a quartz furnace body, a powder storage room, a gas storage room, a temperature control module, etc.; the atmosphere inerting device consists of a high-pressure gas cylinder, a valve group, a precision pressure gauge, It consists of precision vacuum gauge, air compressor, vacuum pump and glove box. According to the test needs, different gas cylinder combinations are used for gas distribution, and the prepared gas under pressure is stored in the gas distribution container. The prepared gas can be delivered to the gas storage chamber of the standard test device, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com