Device and method for calibrating working positions of polishing head and loading and unloading table

A technology of working position and polishing head, which is applied in the manufacturing of electrical components, circuits, semiconductor/solid-state devices, etc., can solve the problems of large amount of sensor detection data, unrealized loading and unloading table centering, and no mention of centering loading and unloading table, etc. Achieve the effect of high calibration efficiency, excellent data processing method, and low installation location requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

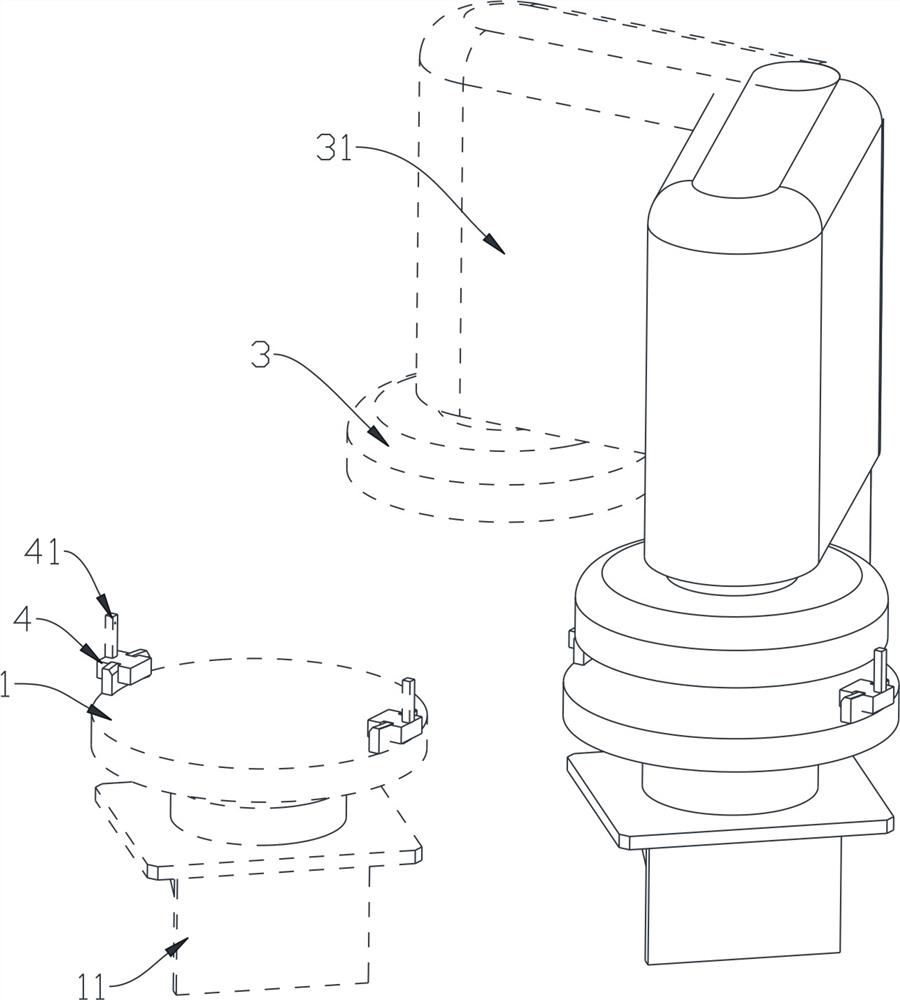

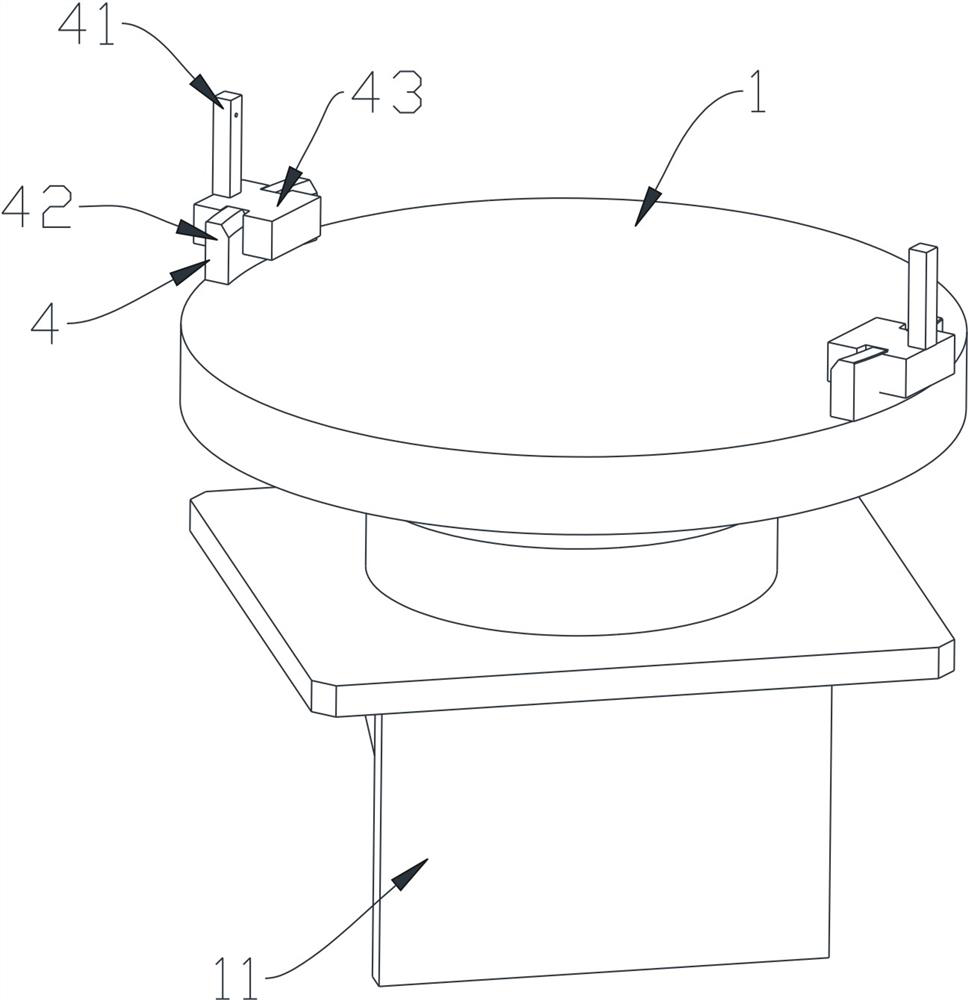

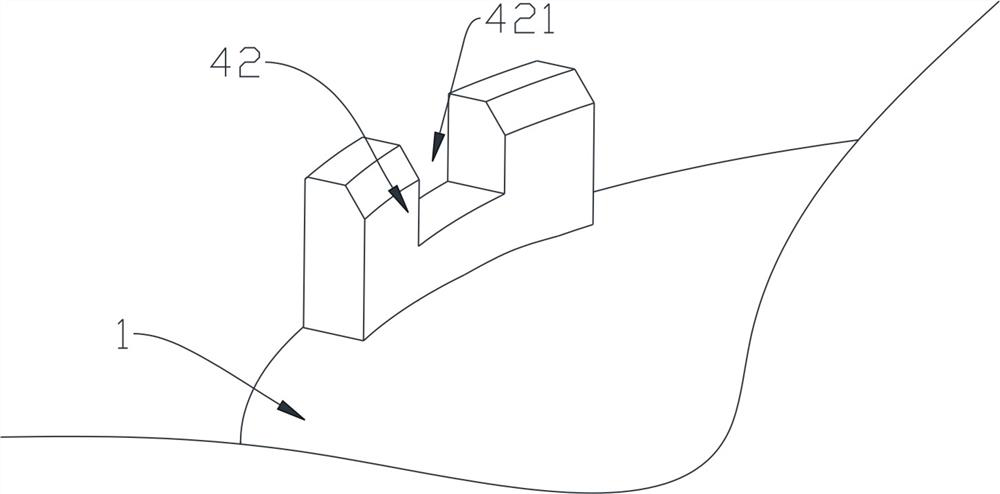

[0092] like Figure 5 , Image 6 As shown, the number of sensors 41 is two at this time, which are not only arranged along the radial direction of the loading and unloading platform 1 , but also along the extending direction of the linear track 2 .

[0093] A method for calibrating the working positions of a polishing head and a loading and unloading table, comprising the following steps:

[0094] Install the sensor assembly 4 to the loading and unloading table 1, manually move the loading and unloading table 1 and the polishing head 3 close to each other, and calibrate the reading of the sensor 41;

[0095] Determine the rotation trajectory 5 of the polishing head 3, and use the angle range where the sensors 41 at both ends of the loading and unloading table 1 can display the reading as the swing range of the polishing head 3, and record the start position and end position, and define two sensors 41 and polishing. The readings of the edge of head 3 are L1 and L2 respectivel...

Embodiment 2

[0102] like Figure 7 , Figure 8 As shown, at this time, the number of sensors 41 is two, which are not only arranged along the radial direction of the loading and unloading platform 1 , but also along the direction perpendicular to the linear track 2 .

[0103] In this embodiment, the method for calibrating the working positions of the polishing head and the loading and unloading table is the same as that in the first embodiment, and will not be repeated.

Embodiment 3

[0105] like Figure 9 , Figure 10 As shown, the number of sensors 41 is two at this time, and they are only arranged along the radial direction of the loading and unloading platform 1 , not along the direction perpendicular to the linear track 2 , nor along the extension direction of the linear track 2 .

[0106] At this time, the working positions of the polishing head and the loading and unloading table can be calibrated with the directions in the first embodiment, and the following methods can also be used for calibration.

[0107] A method for calibrating the working positions of a polishing head and a loading and unloading table, comprising the following steps:

[0108] Install the sensor assembly 4 to the loading and unloading table 1, manually move the loading and unloading table 1 and the polishing head 3 close to each other, and calibrate the reading of the sensor 41;

[0109] Determine the rotation trajectory 5 of the polishing head 3, and use the angle range wher...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com