TFT (Thin Film Transistor) array substrate structure for improving metal residues and manufacturing method of TFT array substrate structure

An array substrate structure and metal residue technology, which is applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve the problems of SD metal residue, short circuit of adjacent SD metal lines, and no improvement, and achieve the elimination of metal Residue, the effect of improving product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

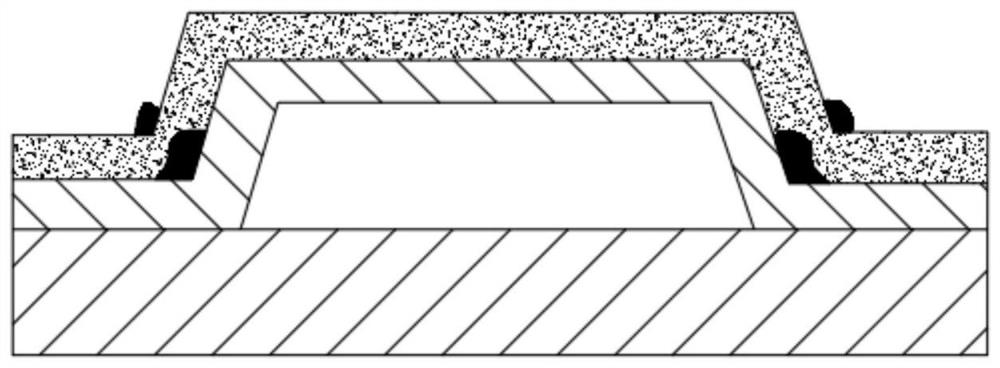

[0033] like figure 1 As shown, the present invention improves a TFT array substrate structure with metal residues, which includes a TFT side glass substrate 1, and a buffer layer 2 with grooves is arranged on the glass substrate 1, and the shape of the grooves is the upper Large and small trapezoidal shape, a GE metal layer 3 is deposited in the groove of the buffer layer, the upper surface of the buffer layer 2 and the GE metal layer 3 are flush, and the GE metal layer 3 is provided with GI insulation layer 4, the GI insulating layer 4 is provided with a PV insulating layer 5.

[0034] Further, the buffer layer 2 is usually made of SiOx, which can not only be used to planarize the glass surface, but also pattern a corresponding groove shape in a specific area.

[0035] Further, the GE metal layer 3 has low resistivity, and aluminum / molybdenum / titanium / nickel / copper / and other metals with excellent electrical conductivity and alloys such as Mo / Al / Mo or Ti / Al / Ti can be selected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com