Thioether compound, preparation method thereof, medical intermediate and application thereof

A compound and thioether technology, applied in the field of thioether compounds and their preparation, can solve problems such as metal residues, and achieve the effects of eliminating metal residues, high yield and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

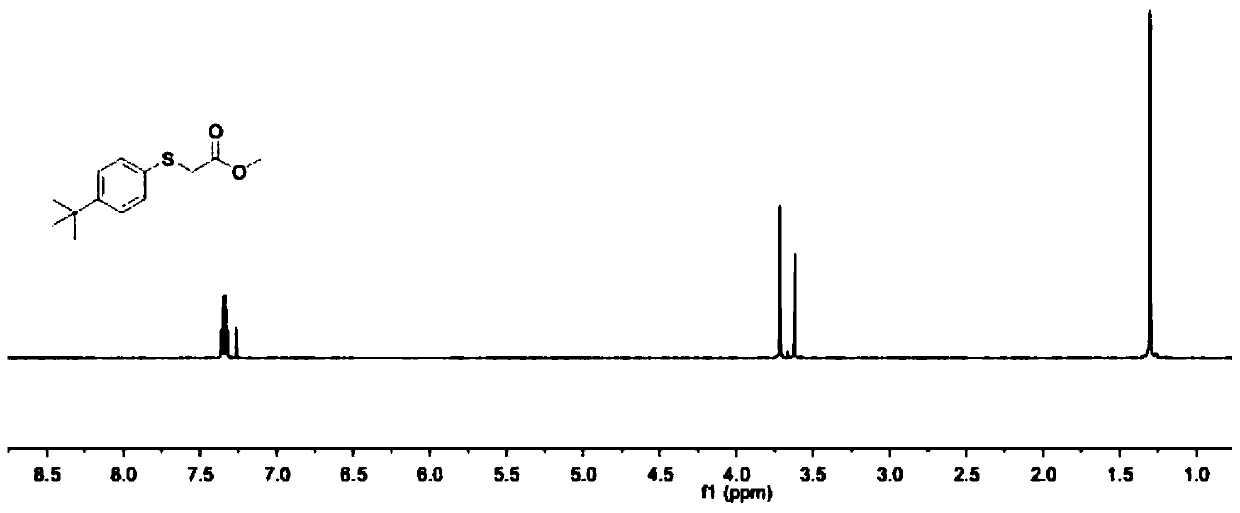

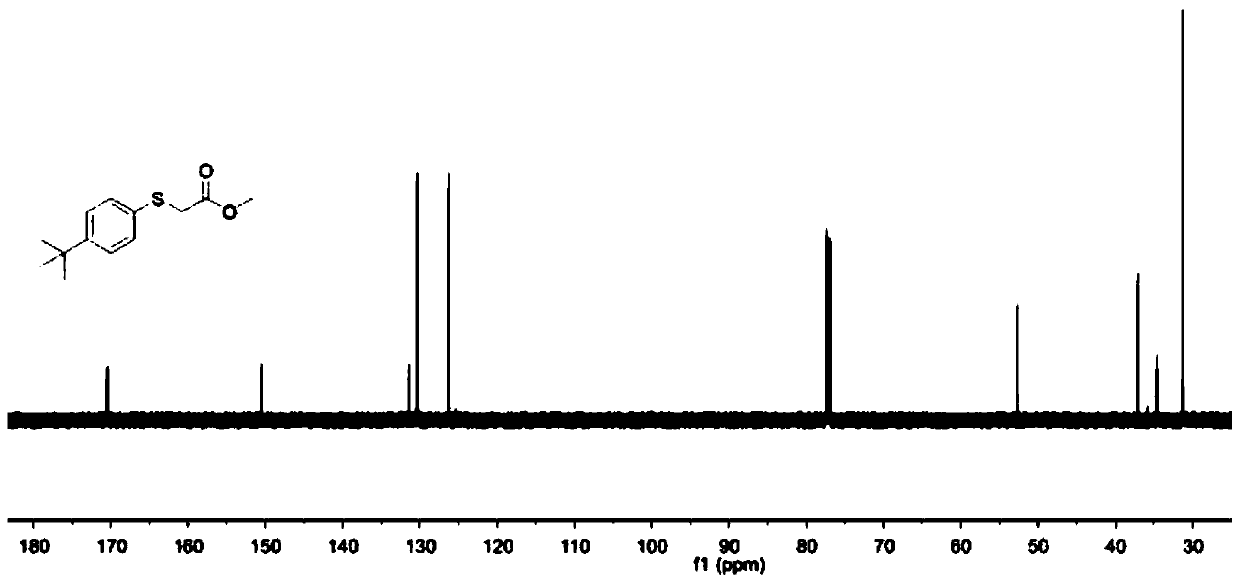

[0045] A thioether compound 001, namely the thioether compound numbered 001, the specific structural formula is:

[0046]

[0047] In this example, the specific synthesis steps of the thioether compound 001 are as follows:

[0048] At room temperature, 1-(tert-butyl)-4-(methylsulfoxide)benzene (60.1 mg, 0.3 mmol), methyl bromoacetate (281.0 mg , 1.8mmol), while adding 0.15mL of 1-butyl-3-methylimidazolium trifluoromethanesulfonate, then placed on a reactor at 100°C for 48h; the reaction system after the reaction was cooled to room temperature ( Usually 25 ℃), after the cooling is completed, the reaction system is washed with water, then extracted three times with ethyl acetate, the organic phase of the three extractions is combined into a 50mL eggplant-shaped bottle, and the Heidolph rotary evaporator (rotating speed is 90rpm, temperature is 40°C, vacuum degree is 0.1Mpa) rotary evaporation treatment for 3min, the residue was separated by column chromatography using 200 me...

Embodiment 2

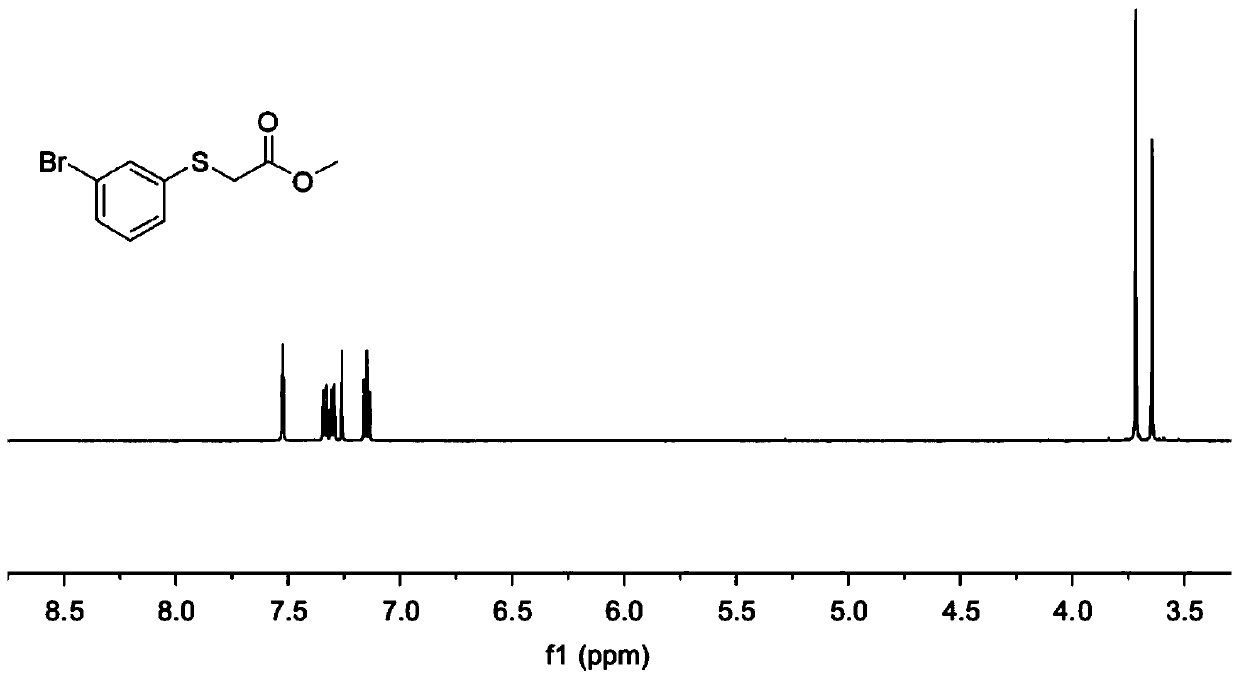

[0054] A thioether compound 002, namely the thioether compound numbered 002, the specific structural formula is:

[0055]

[0056] In this example, the specific synthesis steps of the thioether compound 002 are as follows:

[0057] Add 1-bromo-3-(methylsulfoxide)benzene (67.1mg, 0.3mmol), methyl bromoacetate (281.0mg, 1.8mmol) sequentially to a 4mL pre-dried vial at room temperature , while adding 0.15 mL of 1-butyl-3-methylimidazolium trifluoromethanesulfonate, and then placed on a reactor at 100 ° C for 48 h; the reaction system after the reaction was cooled to room temperature (usually 25 ° C ), after the cooling was completed, the reaction system was washed with water, then extracted three times with ethyl acetate, and the organic phases extracted three times were combined into a 50mL eggplant-shaped flask, and the Heidolph rotary evaporator (rotating speed was 90rpm, temperature was 40°C, vacuum degree of 0.1Mpa) rotary steaming treatment for 3min, the residue was sep...

Embodiment 3

[0063] A thioether compound 003, namely the thioether compound numbered 003, the specific structural formula is:

[0064]

[0065] In this example, the specific synthesis steps of the thioether compound 003 are as follows:

[0066] At room temperature, add 4-(methylsulfoxide)benzaldehyde (51.5mg, 0.3mmol) and methyl bromoacetate (281.0mg, 1.8mmol) successively to a pre-dried vial with a capacity of 4mL, and add 0.15mL of 1-butyl-3-methylimidazolium trifluoromethanesulfonate, then placed in a reactor at 100°C for 48h; the reaction system after the reaction was cooled to room temperature (usually 25°C), cooled After completion, the reaction system was washed with water, and then extracted three times with ethyl acetate, and the organic phases extracted three times were combined into a 50 mL eggplant-shaped flask, and the Heidolph rotary evaporator (90 rpm, 40 °C, and 0.1 Mpa) rotary steaming treatment for 3min, the residue was separated by column chromatography using 200 mes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com