Intermetallic compound catalyst and preparation method thereof

A technology of intermetallic compounds and intermetallic alloys, applied in catalyst activation/preparation, metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, etc., can solve low efficiency, uneven catalyst particle size, Problems such as catalyst particle agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

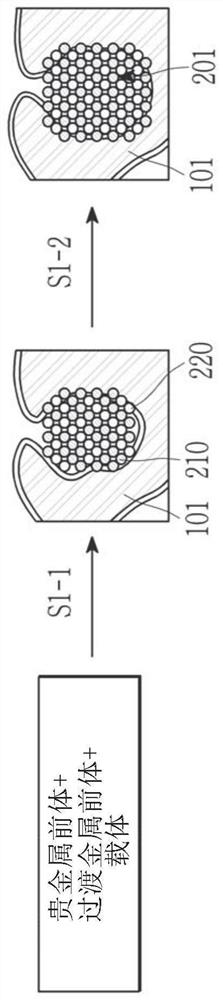

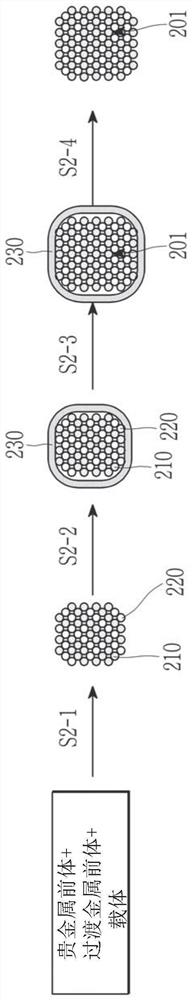

Method used

Image

Examples

Embodiment 1

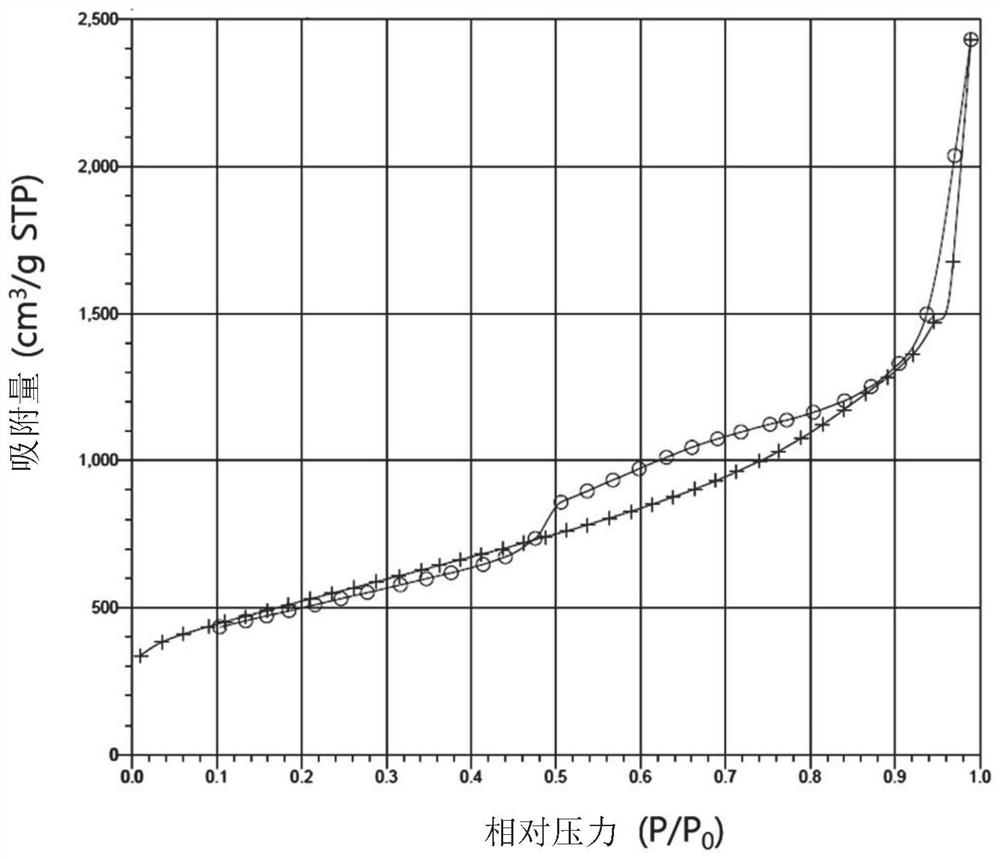

[0105] Prepared with an average pore size of 7nm and a specific surface area of 1000m 2 / g of carbon support (product name: KB300J, manufacturer: Lion).

[0106] Put Pt(acac) 2 , Fe(acac) 3 and carbon support were added to ethylene glycol to prepare a solution of the precursor mixture, using a tip type ultrasonic wave (Sonic and Materials, model VC-500, amplitude 30%, 13 mm solid probe, 20 kHz) under an argon atmosphere at 100 mL of the precursor mixture solution was irradiated with ultrasonic waves at an output of 150 W for 3 hours to form alloy particles in the pores of the carbon support.

[0107] At this time, the addition amount of the noble metal precursor and the transition metal precursor is adjusted so that the atomic ratio of the noble metal and the transition metal can be 2:3.

[0108] The prepared alloy particles were annealed at a temperature of 800° C. for 2 hours in an atmosphere of 4% hydrogen and 96% air, thereby forming intermetallic alloy particles. Th...

Embodiment 2

[0110] The intermetallic compound catalyst was prepared according to the same method as in Example 1, except that the carbon support used was prepared by annealing the carbon support of Example 1 at a temperature of 1500° C. for 2 hours, and had an average of 10 nm. Aperture and 600m 2 / g specific surface area.

Embodiment 3

[0112] The intermetallic compound catalyst was prepared according to the same method as in Example 1, except that the carbon support used was prepared by annealing the carbon support of Example 1 at a temperature of 2000° C. for 2 hours, and had an average of 13 nm. Aperture and 300m 2 / g specific surface area.

[0113] Evaluation method: Evaluation of fuel cell performance of intermetallic compound catalysts Each prepared intermetallic compound catalyst (40% by weight) was dispersed in n-propanol solvent at an ionomer to carbon ratio (I / C) of 0.6 to prepare slurry.

[0114] The slurries were respectively coated on release paper to make cathode and anode (cathode: Pt loading was 0.1 mg / cm 2 , anode: Pt loading is 0.025mg / cm 2 ) and insert a Nafion membrane between the cathode and anode to make a membrane electrode assembly (MEA).

[0115] The fabricated MEA was connected to an apparatus for evaluating fuel cells, and then heated at a temperature of 65 °C, a bar pressure of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com