Rice bran protein and processing method thereof

A rice bran and protein technology, applied in the field of vegetable protein processing, can solve the problems of poor product functionality, low rice bran protein purity and extraction yield, etc., and achieve the effects of good hydrophilic solubility, satisfying allergies, and good foaming activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0088] In step (2) of the rice bran protein concentrate preparation method of the present invention, the rice bran can be contacted with water, and then the pH of the contact solution can be adjusted, or the rice bran can be contacted with an alkaline aqueous solution, and the pH of the contact solution can be optionally adjusted.

[0089] In the step (2) of the rice bran protein concentrate preparation method of the present invention, the contact liquid may also be subjected to colloid milling treatment before centrifugation. Colloid milling can be performed using any commercially available colloid milling equipment. The number of colloid mill treatments can be arbitrary, as a non-limiting example, the number of colloid mills is 1-4.

[0090] The homogenization operation of the present invention can be realized by one or more of ultrasound, high-pressure micro-jet and high-pressure homogenization, and the homogenization of the present invention can be achieved by any commerci...

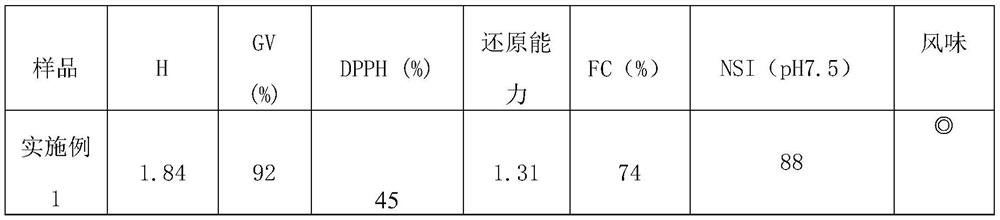

Embodiment 1

[0123] Weigh 100g of fresh full-fat rice bran after crushing and sieving (40 mesh), put it into a heat preservation bucket, add liquid nitrogen to cover the rice bran, cover the heat preservation cover, and keep it for 20min (continuously add liquid nitrogen during this process, keep the liquid nitrogen All covered with rice bran powder), and then let the liquid nitrogen evaporate to dryness, continue to add liquid nitrogen to cover the rice bran with liquid nitrogen, cover with a heat preservation cover, keep for 10 minutes, and then wait for the liquid nitrogen to volatilize, and finally collect the pretreated full-fat rice bran. Add 600 g of water to the pretreated rice bran, stir evenly, adjust the pH of the suspension to 10.5, place it in a 50°C water bath and stir for 2 hours, set the colloid mill gear gap to 10 μm, and overmill the suspension once. Then adjust the gear gap of the colloid mill to 5 μm, repeat the overgrinding twice, centrifuge at 3000g for 10min, collect ...

Embodiment 2

[0125] Weigh 100g of fresh full-fat rice bran after crushing and sieving (40 mesh), put it into a heat preservation bucket, add liquid nitrogen to cover the rice bran, cover the heat preservation cover, and keep it for 20min (continuously add liquid nitrogen during this process, keep the liquid nitrogen All covered with rice bran powder), and then let the liquid nitrogen evaporate to dryness, continue to add liquid nitrogen to cover the rice bran with liquid nitrogen, cover with a heat preservation cover, keep for 10 minutes, and then wait for the liquid nitrogen to volatilize, and finally collect the pretreated full-fat rice bran. Add 600 g of water to the pretreated full-fat rice bran, stir evenly, adjust the pH of the suspension to 9.6, place it in a 50°C water bath and stir for 2 hours, and use the same colloid mill conditions in Example 1 to colloid the suspension. Grinding, centrifuging at 3000g for 10min, collecting the first lipid-containing supernatant, and adding 400g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com