Thermal expansion microbead, pressure-sensitive adhesive capable of being thermally peeled repeatedly and containing thermal expansion microbead, reflective film and preparation method of thermal expansion microbead

A technology of heat-expandable microbeads and pressure-sensitive adhesives, which is applied in the field of reflective film and its preparation, can be repeatedly heat-peeled pressure-sensitive adhesives, and heat-expandable microbeads. Moderate foaming temperature and high foaming ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

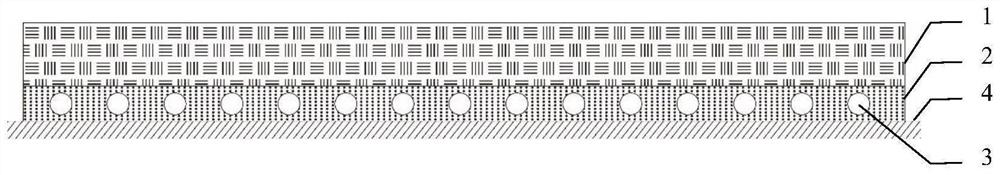

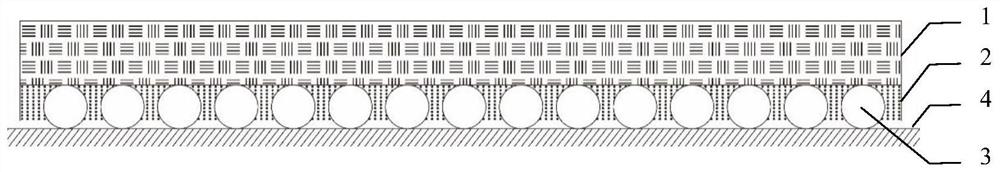

[0026] As mentioned in the background art, it is difficult for the existing luminescent film to achieve thermal peeling or peeling problems such as residual glue during thermal peeling. In order to improve this situation, in a typical embodiment of the present application, a thermal expansion micro A preparation method of beads, the preparation method comprises: dropping solution A into solution B to obtain mixed suspension solution C; wherein solution A is a mixed solution of NaCl and NaOH, and solution B is MgCl 2 , NaNO 3 and the mixed solution of SDS; the monomer, the toughening agent, the initiator, the foaming agent and the crosslinking agent are mixed to obtain a suspension polymerization system D; the mixed suspension solution C and the suspension polymerization system D are mixed and reacted to obtain thermally expandable microbeads .

[0027] By adopting the method of the present application, adopting the suspension polymerization method, and by controlling the type...

Embodiment 1

[0060] 1. Preparation of heat-expandable microbeads

[0061] 1) 35g of NaCl and 28g of NaOH solids were added to 100mL of deionized water, and after strong magnetic stirring, the solid particles were completely dissolved to obtain solution A. 40g MgCl 2 , 5gNaNO 3 and 6 g of sodium dodecyl sulfate (SDS) were sequentially dissolved in 100 mL of deionized water, and after stirring uniformly, solution B was obtained. Under stirring, the above solution A was slowly added dropwise to the solution B to obtain a mixed suspension solution C.

[0062] 2) Combine 48g alkene nitrile (AN), 12g methyl methacrylate (MMA) and 6g methacrylic acid (MAA) monomer with 1.2g styrene-butadiene copolymer toughening agent, and 1.5g benzene peroxide The formyl (BPO) initiator is mixed uniformly, then 20 g of isooctane foaming agent and 2 g of ethylene glycol dimethacrylate (EGDMA) crosslinking agent are added to the mixed solution, and the suspension polymerization system D is obtained after stirri...

Embodiment 2

[0068] 1. Preparation of heat-expandable microbeads

[0069] Similar to Example 1, the difference is:

[0070] The addition amount of styrene-butadiene copolymer toughening agent is 1.35g;

[0071] The addition amount of benzoyl peroxide (BPO) initiator is 2.0g;

[0072] The foaming agent is isooctane, and the addition amount is 25g;

[0073] The amount of ethylene glycol dimethacrylate (EGDMA) crosslinking agent added was 2.5 g.

[0074] 2. The preparation of heat-peelable pressure-sensitive adhesive and reflective film and the preparation of reflective film

[0075] The specific implementation method for the preparation of the repeatable heat-peelable pressure-sensitive adhesive and the reflective film is similar to that of Example 1, except that:

[0076] The amount of ethyl acetate diluent is 250 parts;

[0077] The dosage of epoxy resin type crosslinking agent is 4 parts;

[0078] The dosage of vinyl silicone resin modifier is 3 parts;

[0079] The dosage of terpen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Onset expansion temperature | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com