Clinker free calcium content soft measurement method based on time lag XGBOOST model

A technology of time lag and free calcium oxide, which is applied in the field of cement clinker production, can solve the problems of small amount of data in the industrial field, delay in obtaining results, and difficult to predict effects, so as to accurately capture time-varying characteristics and solve over-fitting Phenomena, Effects of Solving Variable Drift

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

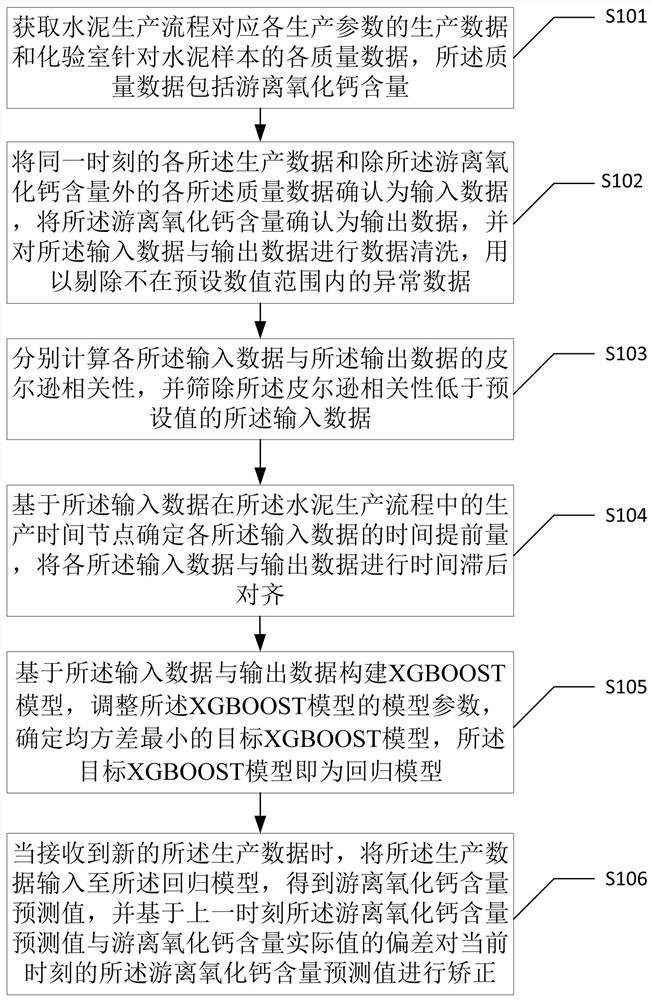

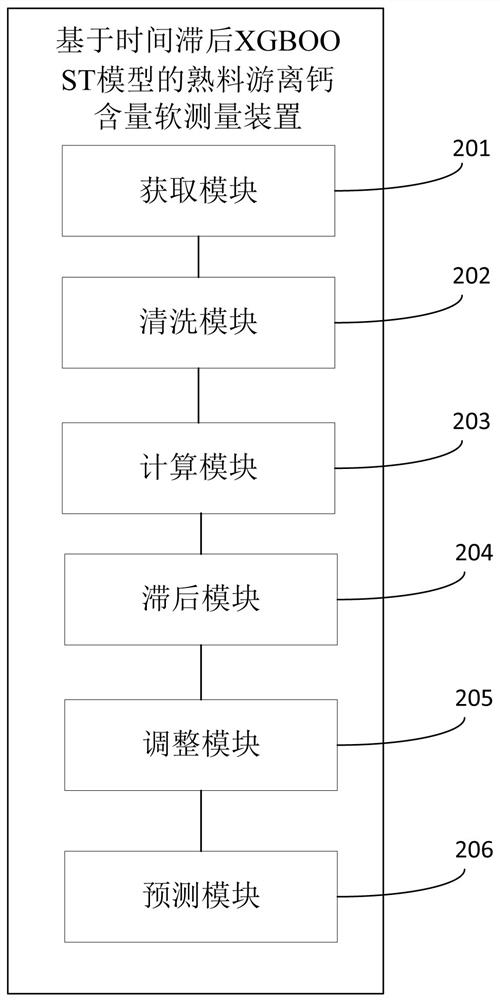

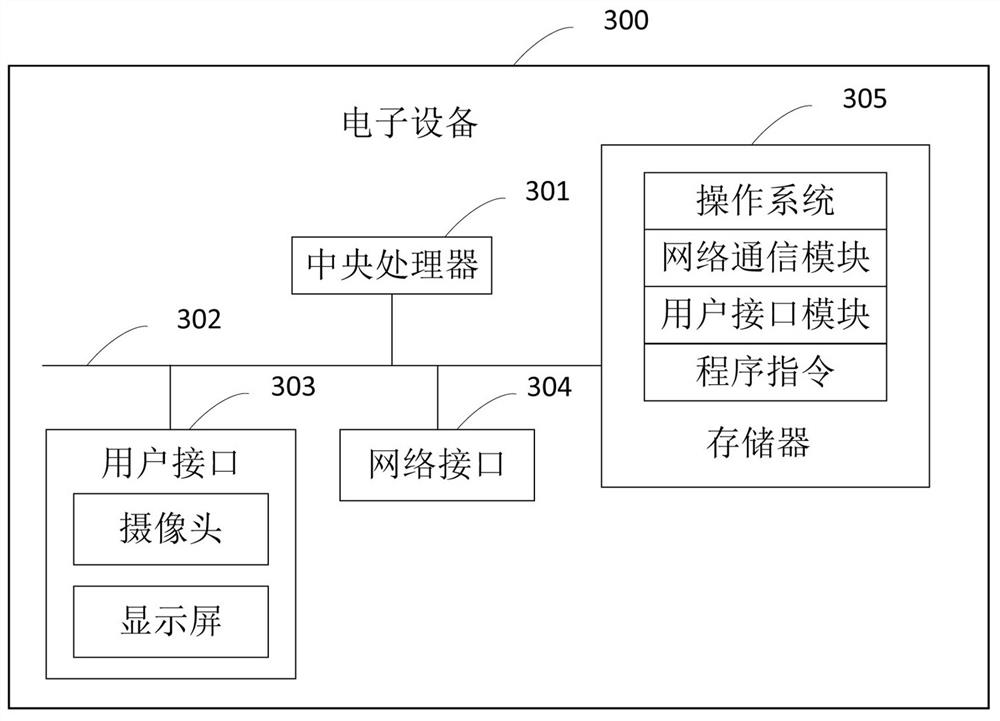

[0041] The technical solutions in the embodiments of the present application will be clearly and completely described below with reference to the accompanying drawings in the embodiments of the present application.

[0042]In the following introduction, the terms "first" and "second" are used for descriptive purposes only, and should not be construed as indicating or implying relative importance. The following description provides multiple embodiments of the present application, and different embodiments may be substituted or combined, so the present application may also be considered to include all possible combinations of the same and / or different embodiments described. Thus, if one embodiment includes features A, B, C and another embodiment includes features B, D, the application should also be considered to include all other possible combinations of one or more of A, B, C, D example, although this example may not be explicitly described in the following content.

[0043] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com