Liner-free label

A label and web technology, applied in the direction of identification devices, instruments, cardboard items, etc., can solve the problems of pollution, sticky adhesive pollution, etc., and achieve the effect of reducing adhesive residue and easy mechanical cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

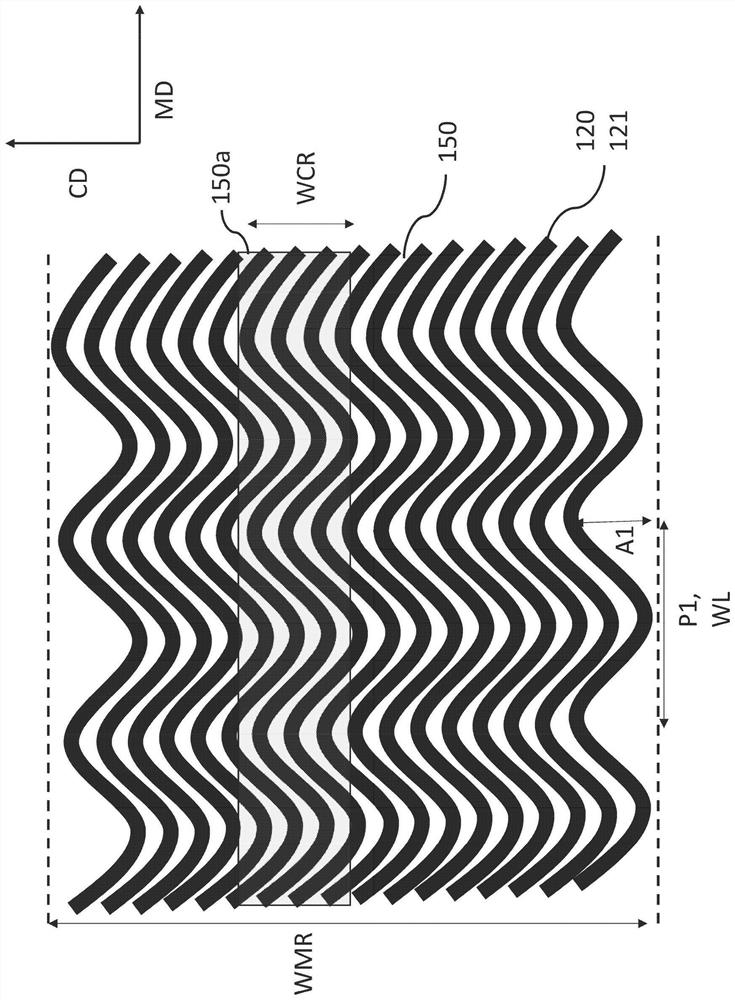

[0394] Reference machine rolls including adhesive strips but without position-alternating continuous adhesive strips, as well as novel rolls including alternating-position adhesive strips, were made.

[0395] The reference roll includes adhesive strips with adhesive-free areas between the adhesive strips. The width of the adhesive strip is substantially the same as the width of the adhesive-free area.

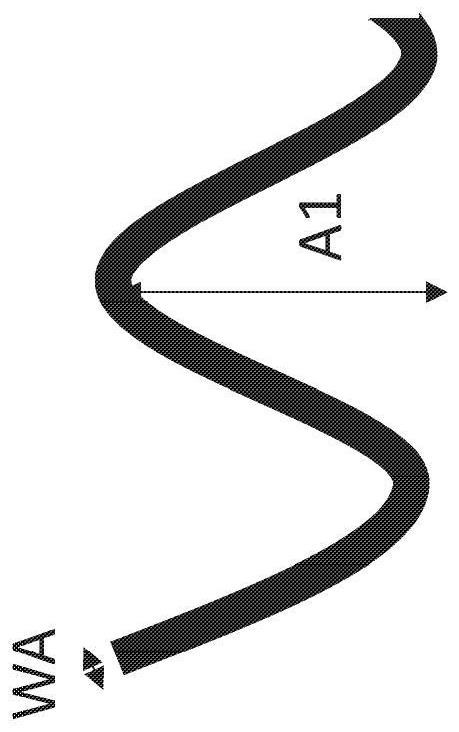

[0396] The novel rolls included alternating positions of adhesive strips, including adhesive-free areas of the same width as the reference roll and adhesive strips of the same width. The width of the alternating strips of adhesive was 25 mm. The frequency of the actuators during the manufacturing steps of the alternating-position adhesive strips was 1 Hz. The web is driven at a speed of about 200 meters / 60 seconds, so moves a few meters per second.

[0397] Machine rolls are slit by using a slitter. The width and length of each customer roll were varied during testing.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com