Composite heating body with multiple vent holes

A technology of ventilation holes and heating body, applied in the direction of tobacco, can solve the problems of large suction resistance, increase the cost of atomization device, and inability to smoke, and achieve the effect of being suitable for industrial production, suitable for smoke temperature, and preventing the penetration of e-liquid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

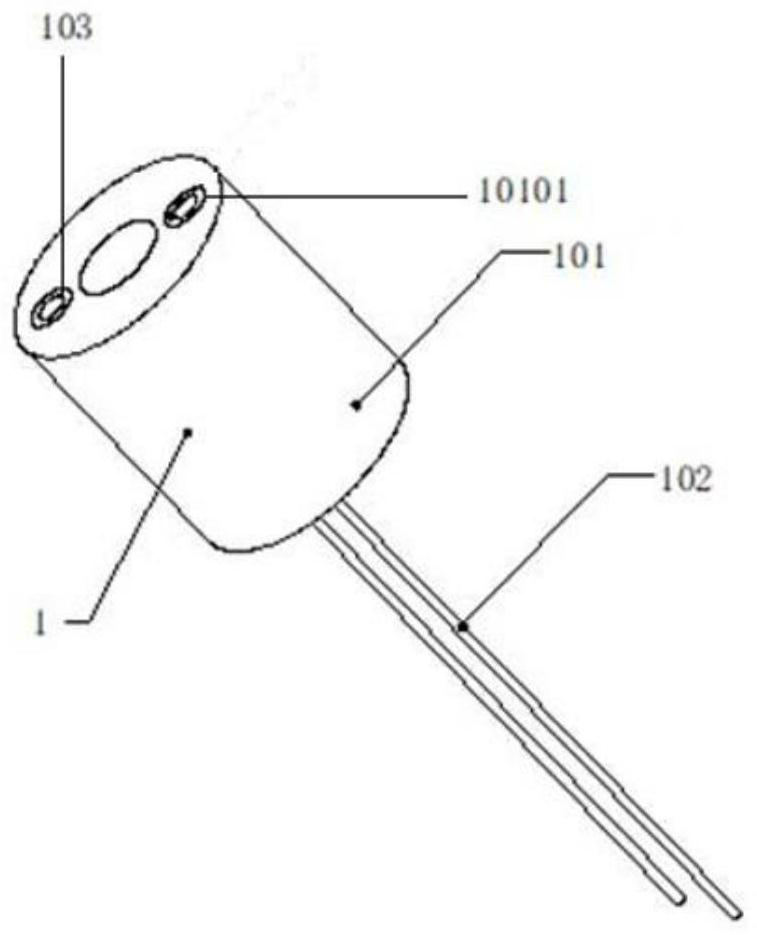

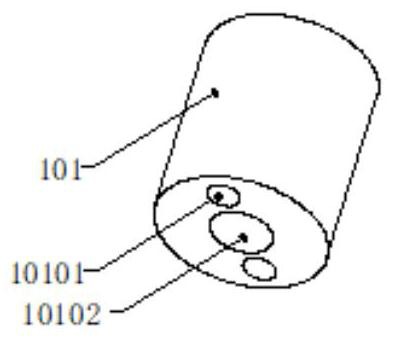

[0047] like figure 1 As shown, a composite heating element 1 with multiple air holes includes a ceramic substrate 101 and a heating element 102 . The ceramic substrate 101 is a hollow columnar structure, made of alumina, and has a diameter of 5 mm.

[0048] The ceramic base 101 is provided with two ventilation holes, one of which runs through the center of the ceramic base 101 and is the main ventilation hole 10102 , with a diameter of 2 mm, a material selected from alumina, a porosity of 55%, and a pore diameter of 35 μm. Two auxiliary ventilation holes 10101 are provided bypassing the main ventilation hole 10102 , and the auxiliary ventilation holes 10101 penetrate through the ceramic base 101 and are parallel to the main ventilation hole 10102 .

[0049] The auxiliary ventilation hole 10101 is also inserted with an auxiliary ventilation pipe 103 whose wall material is impermeable to e-liquid, the height of the auxiliary ventilation pipe 103 is not less than the height of t...

Embodiment 2

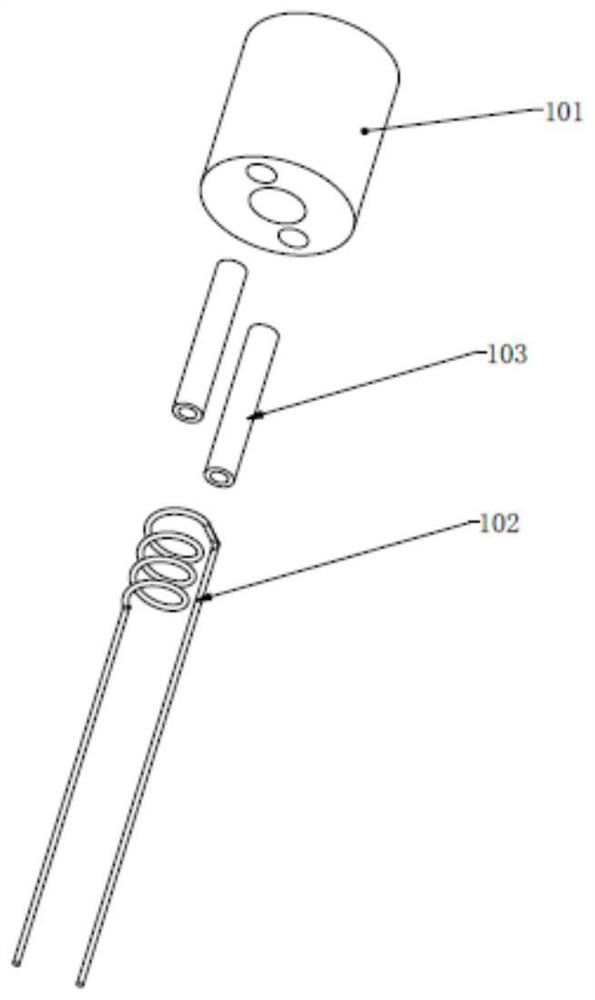

[0053] The preparation method of a composite heating element with multiple ventilation holes described in Embodiment 1, the method comprises the following steps:

[0054] (1) At least one auxiliary ventilation tube 103 is prepared by injection molding or die casting or sintering or machining.

[0055] (2) Obtaining the first ceramic body by injection molding or tape casting, and opening the longitudinal center of the first ceramic body to form the main ventilation hole 10102, and at the same time embedding the auxiliary ventilation pipe 10101 in the first ceramic body The bypass of the body main vent hole 10102 obtains the second ceramic green body.

[0056] (3) The heating element is embedded on the surface of the main vent hole to obtain a third ceramic body.

[0057] (4) Sintering and molding the third ceramic green body to obtain a composite heating element with multiple air holes.

Embodiment 3

[0059] like Figure 5 As shown, an atomizing device with a composite heating element with multiple ventilation holes. The device includes a composite heating body 1 , an air pipe 2 , an oil storage bin 3 , a sealing silicone 4 , a suction nozzle 5 and a power source 6 .

[0060] The oil storage bin 3 is a hollow structure, and the upper part is tightly connected with the sealing silica gel 4 .

[0061]The composite heating element 1 is located inside the airway pipe 2 and has a hollow columnar structure. The axial outer surface of the composite heating element 1 is a liquid absorption surface, and the axial inner surface of the main vent hole 10102 is an atomizing surface.

[0062] The air duct 2 is a hollow tubular structure, located inside the oil storage bin, with oil inlet holes on both sides, and a composite heating element 1 on the inner side.

[0063] The power supply 6 is installed at the bottom of the entire atomizing device for controlling the output of the entire ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com