Pickling mechanism for producing glass fibers

A glass fiber and pickling technology, applied in the field of pickling mechanism, can solve the problems of poor wear resistance, large glass fiber shielding area, incomplete pickling of glass fiber rolls, etc., and achieves the effect of easy connection, easy installation and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

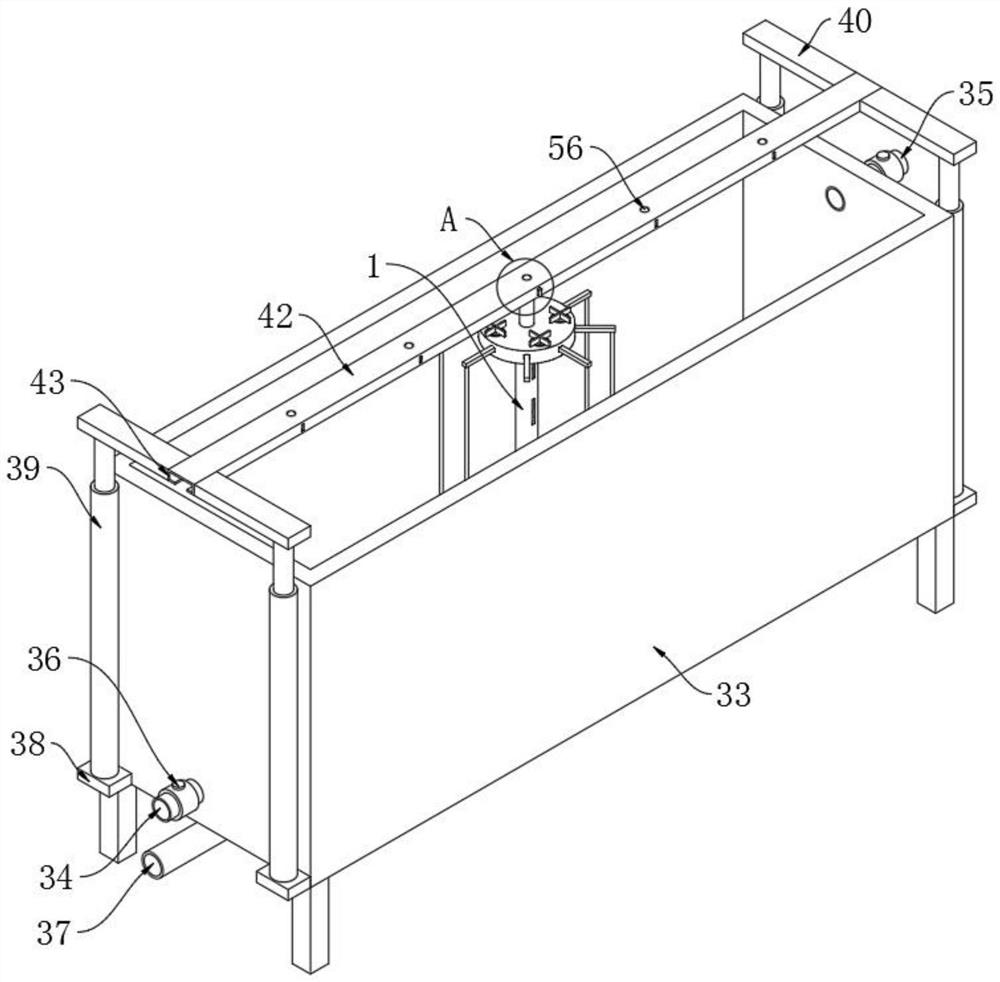

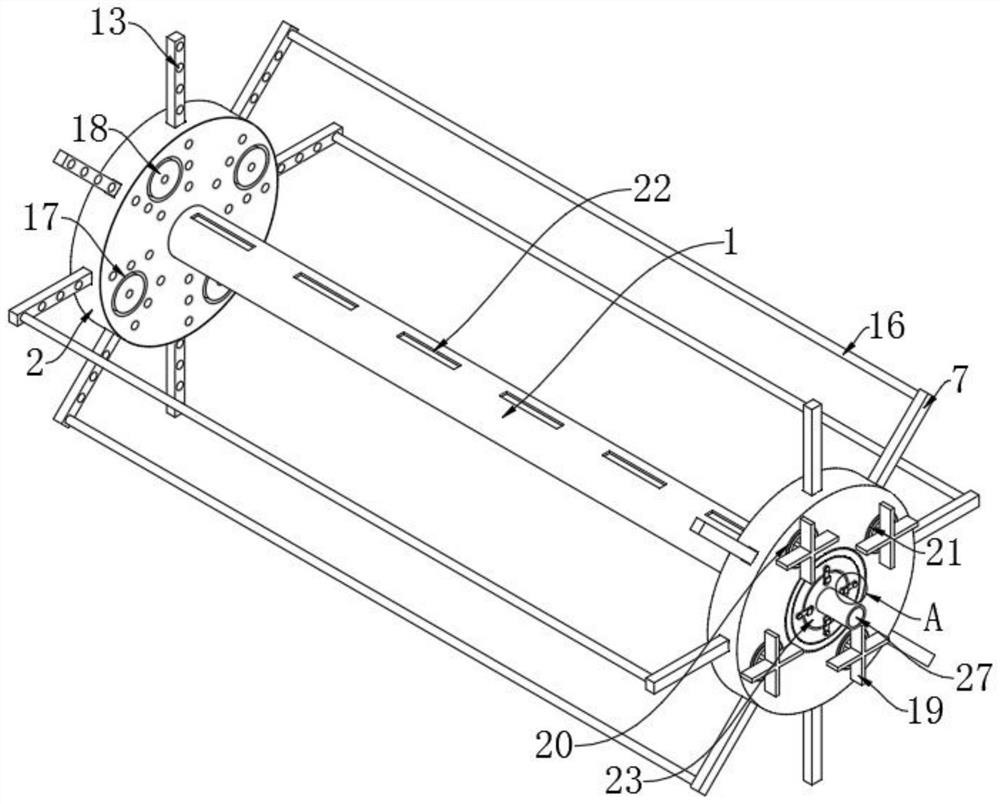

[0046] Example: as Figure 1-14 As shown, a pickling mechanism for producing glass fibers includes a pickling tank 33 and a reel 1 arranged in the pickling tank 33, and two sides of the pickling tank 33 are respectively provided with a second valve 36 installed The liquid inlet pipe 34 and the liquid outlet pipe 35, the bottom of the pickling tank 33 is provided with an acid liquid delivery pipe 37 with a plurality of liquid inlet cannulas 41, and the pickling tank 33 is provided with a T-shaped chute 43. The sliding rail 42, both ends of the sliding rail 42 are provided with a lifting mechanism for adjusting the height of the sliding rail 42, and the lifting mechanism includes electric push rods 39 arranged on both sides of the pickling tank 33;

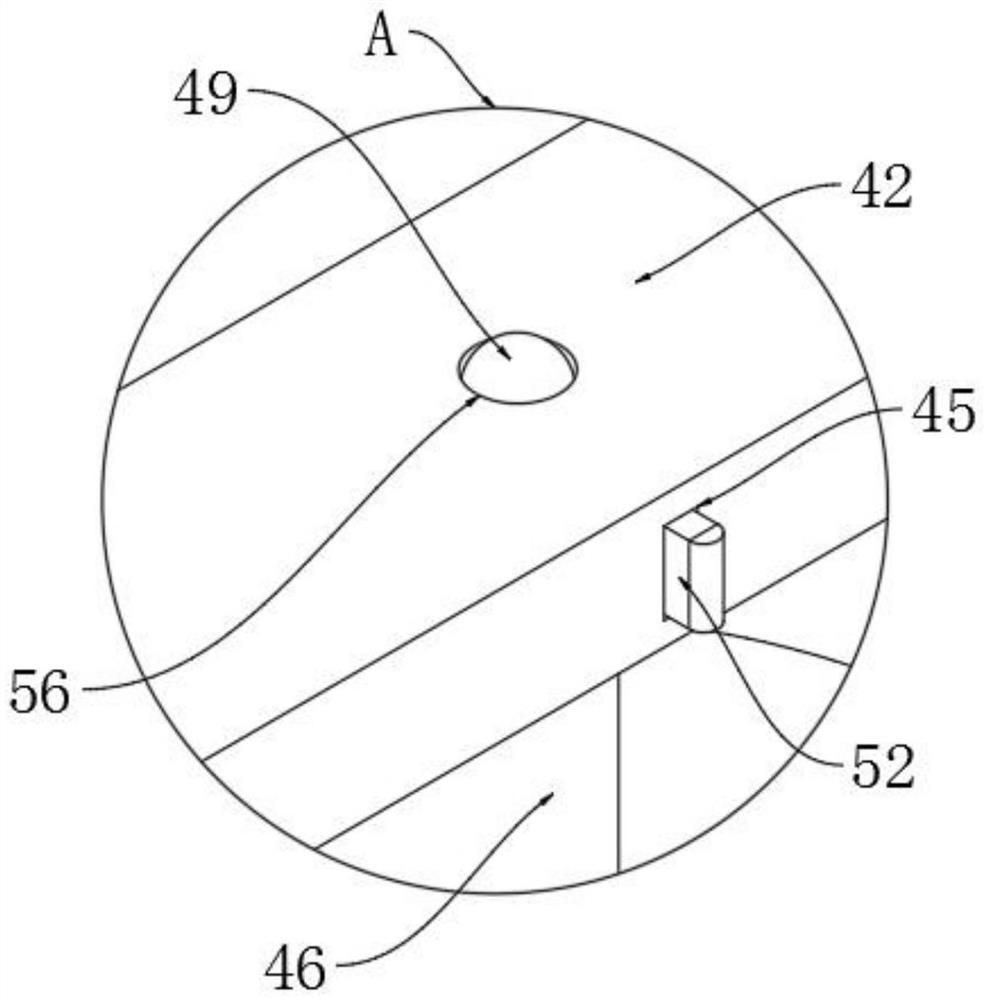

[0047] The slide rail 42 is provided with a plurality of clamping grooves 56 corresponding to the plurality of liquid inlet cannulas 41 one-to-one. The interior of the slide rail 42 is provided with a T-shaped block connected to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com