Method for quickly clarifying and deastringing persimmon vinegar

A persimmon vinegar and fast technology, which is applied in the preparation of vinegar, biofuels and other directions, can solve the problems of lack of measured dose of fermented raw vinegar, difficulty in adjusting and controlling costs, affecting the effect of precipitation and clarification, etc., so as to improve premixing efficiency and save money Production time, effect of increasing uncertainty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

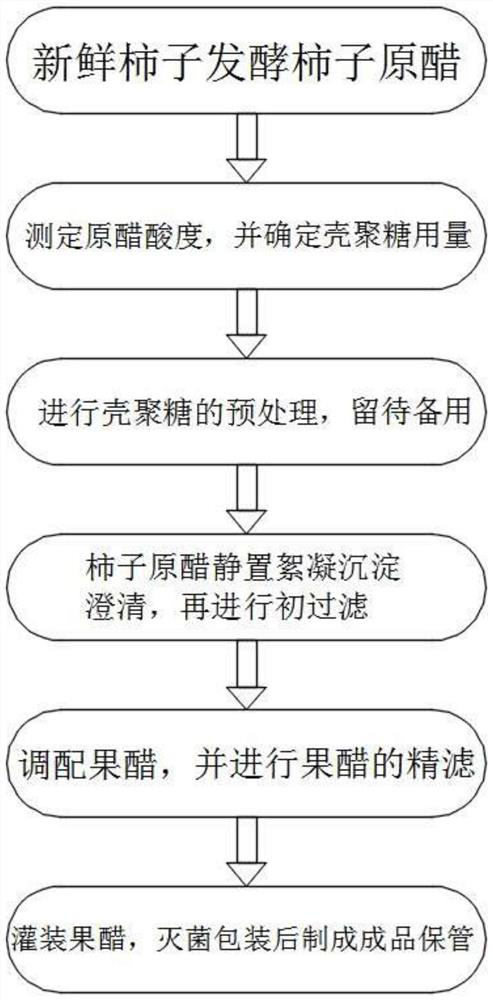

[0036] like Figure 1-6 As shown, the present invention provides a method for rapid clarification and deastringency of persimmon vinegar, and the method for rapid clarification and deastringency of persimmon vinegar comprises the following steps:

[0037] Step 1. Fresh persimmons are fermented with persimmon raw vinegar. The fresh persimmons are subjected to a two-step fermentation method to convert the sugars of the persimmons into acetic acid, and filtered through a plate and frame to obtain the persimmon raw vinegar. The two-step fermentation method is to add Angel Saccharomyces cerevisiae first. Carry out alcohol fermentation, convert the persimmon fructose into alcohol, and after the alcohol fermentation, add Acetobacter pasteurii for acetic acid fermentation, and completely convert the produced alcohol into acetic acid;

[0038]Step 2, measure the original acetic acid degree, and determine the amount of chitosan, adopt acid-base titration, titrate with sodium hydroxide N...

Embodiment 2

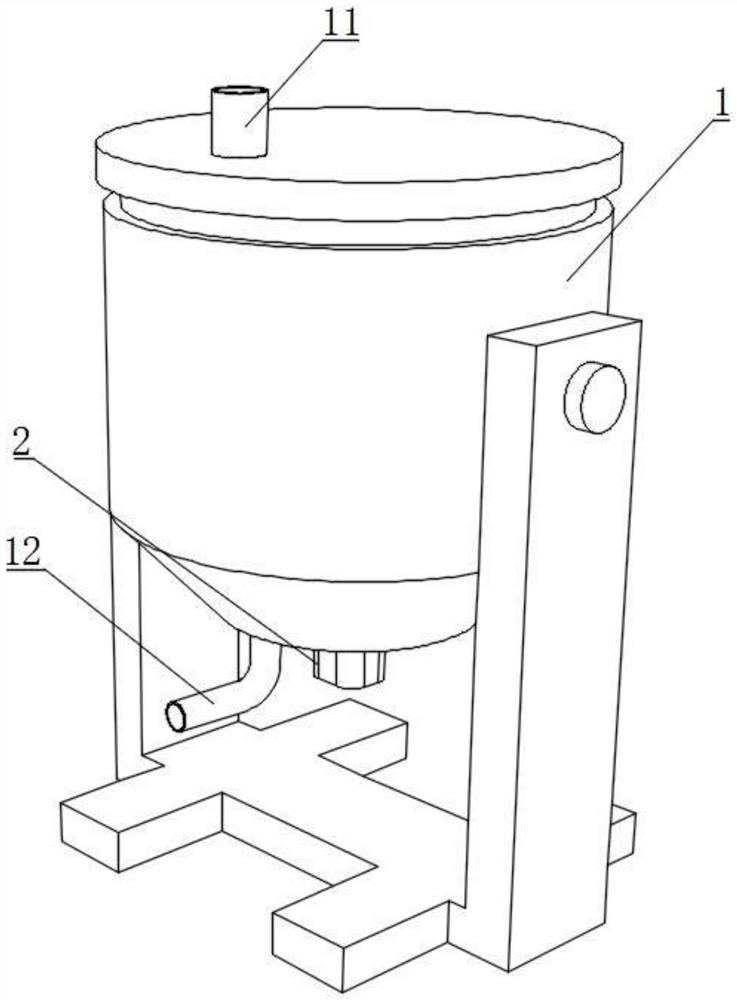

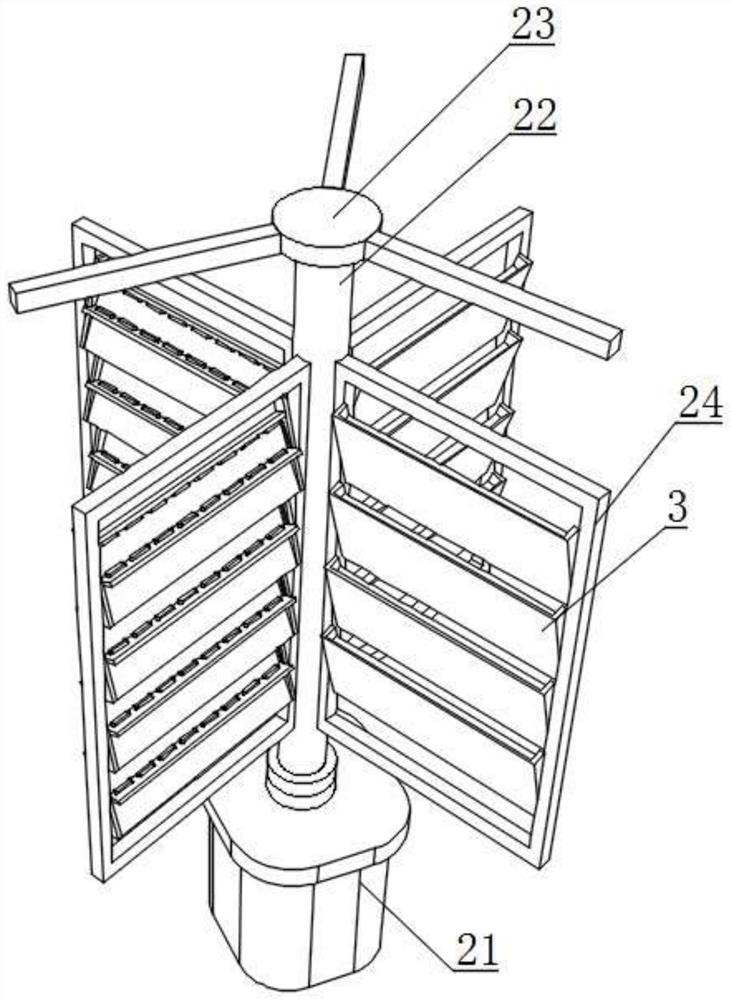

[0044] like Figure 1-6 As shown, on the basis of Example 1, the present invention also provides a chitosan pretreatment mixing device, including a pretreatment mixing tank 1, a conveying pipe 11 is arranged on the top of the pretreatment mixing tank 1, and a pretreatment mixing tank 1 The bottom of the pretreatment mixing tank 1 is fixedly installed with a discharge pipe 12, and the middle of the bottom surface of the pretreatment mixing tank 1 is fixedly installed with a mixing mechanism 2. The mixing mechanism 2 includes a drive motor 21, a stirring rod 22, a positioning frame 23 and a stirring frame 24. The inner wall of the stirring frame 24 The mixing plate 3 is rotatably connected to the upper surface, and the limited rotating shafts 31 are fixedly installed on both sides of the mixing plate 3. The surface of the mixing plate 3 is provided with a magnetic pole one 34 and a magnetic pole two 36, and the bottom surface of the magnetic pole one 34 is fixedly connected with ...

Embodiment 3

[0046] like Figure 1-6 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: preferably, the outer surface of the limiting shaft 31 is rotatably connected to the inner wall of the stirring frame 24, and the inner wall of the mixing plate 3 is provided with a movable groove 32. , the two ends of the movable mixing plate 33 are slidably connected with the inner wall of the movable groove 32, the inner wall of the movable groove 32 is fixedly connected with a resilient member 37, and one end of the resilient member 37 is fixedly connected with the outer surface of the movable mixing plate 33, The top of the magnetic pole two 36 is fixedly connected with a fixed plate 35, and the fixed plate 35 is fixedly installed on the inner wall of the mixing plate 3. The mixing plate 3 is washed by the flow of water, and the moving mixing plate 33 and the magnetic pole one 34 are pushed toward the magnetic pole. The second 36 moves, and is pushed by the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com