Side wall flue gas circulation system of sintering machine

A flue gas circulation and circulation system technology, applied in the field of metallurgy, can solve problems such as increased pollution control costs, increased oxygen content in sintering flue gas, and increased burden on environmental protection facilities, so as to reduce flue gas treatment costs and flue gas emissions , The effect of improving the sintering environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following description and drawings sufficiently illustrate specific embodiments of the invention to enable those skilled in the art to practice them. Other embodiments may include structural, logical, electrical, process, and other changes. The examples represent only possible variations. Unless expressly required, individual components and functions are optional and the order of operations may vary. Portions and features of some embodiments may be included in or substituted for those of other embodiments.

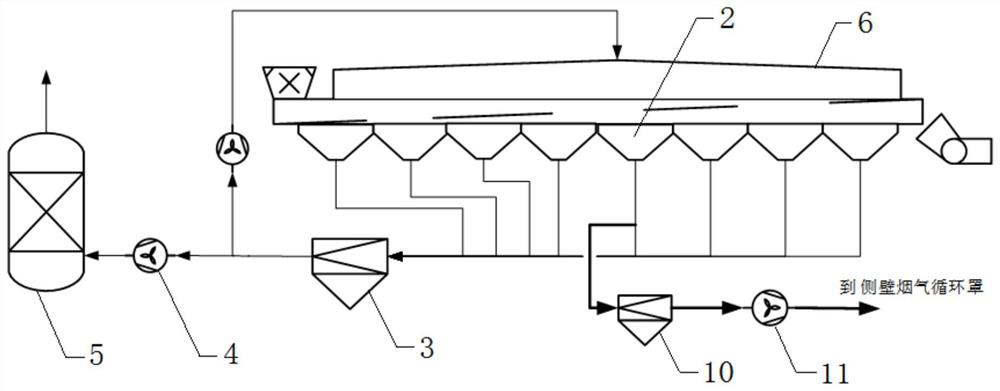

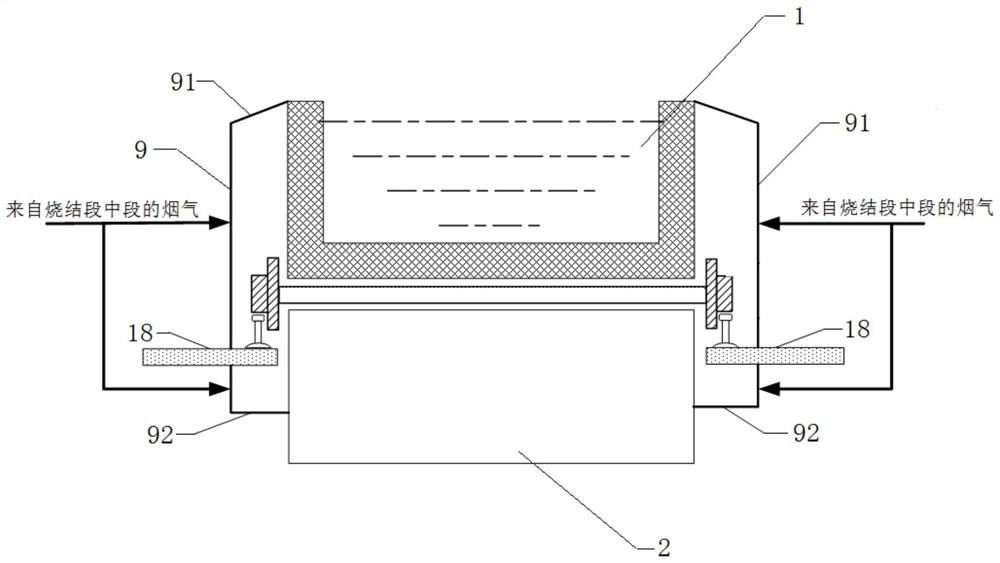

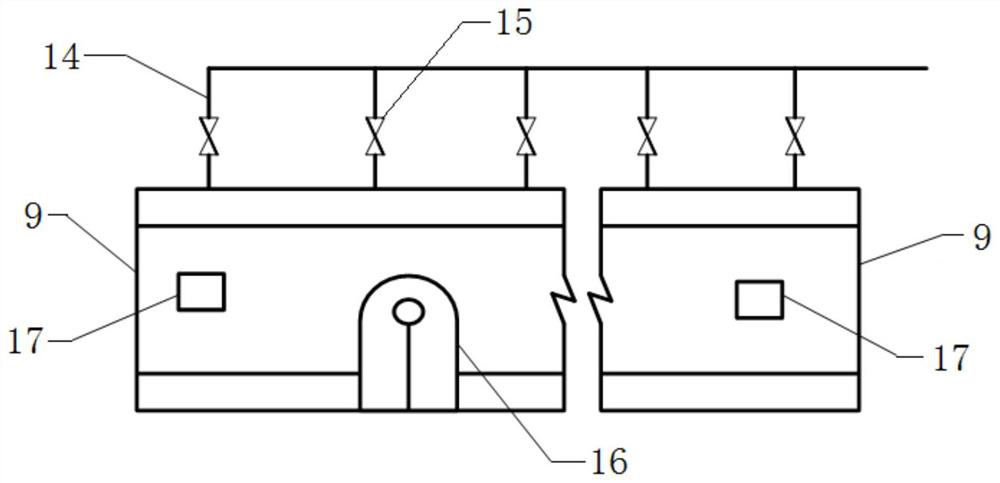

[0021] like Figure 1-5 As shown, in some illustrative embodiments, the present invention provides a sintering machine sidewall flue gas circulation system that realizes the circulation of sintering machine flue gas in the iron and steel industry, reduces sintering flue gas emissions while reducing oxygen content, and achieves energy saving Low carbon operation.

[0022] Below the trolley 1 of the sintering machine is provided a bellows 2 for collecting flue...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com