Method for equivalently simulating bending of fuel assembly in pressurized water reactor core

A fuel assembly, equivalent simulation technology, applied in the fields of fuel elements, greenhouse gas reduction, geometric CAD, etc., can solve the problems of core neutron slowdown, change, low efficiency, etc., achieve simple modeling, enhance safety, The effect of improving economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments.

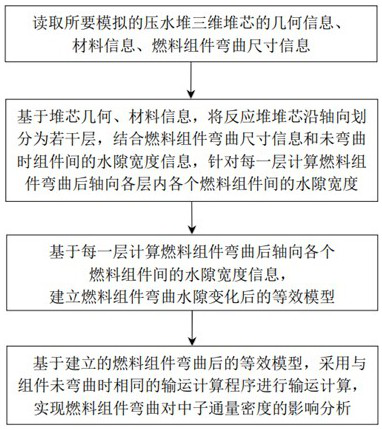

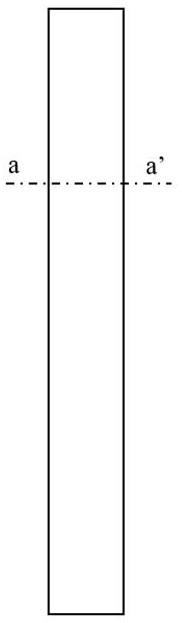

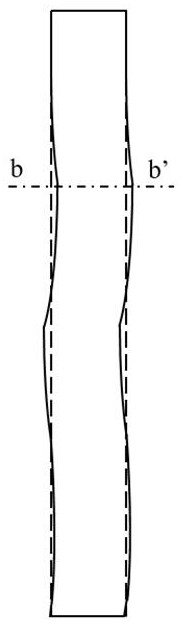

[0023] The specific steps of the method of the present invention are as follows: figure 1 shown. The present invention divides the three-dimensional pressurized water reactor core to be simulated into several layers along the axial direction. In each layer, based on the water gap width when the pressurized water reactor fuel assembly is not bent and the bending size of the fuel assembly, according to the surrounding area of the fuel assembly before and after bending According to the principle of conservation of the number of atoms in the water gap material, by keeping the water gap width before and after bending unchanged, changing the nuclei density of all nuclides in the water gap after bending, the equivalent model of the surrounding water gap caused by the bending of the fuel assembly is established; according to the established ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com