Crystallizer copper plate quality optimization method and system based on thermal conductivity evaluation

A technology of crystallizer copper plate and thermal conductivity, applied in the field of data processing, can solve the problems of thermal conductivity influence and poor thermal conductivity, and achieve the effect of ensuring comprehensiveness, quality optimization, and normalizing data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

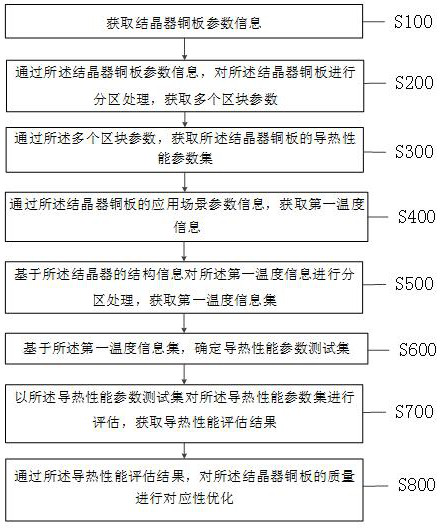

[0025] like figure 1 As shown, the present application provides a method for optimizing the quality of a mold copper plate based on thermal conductivity evaluation, the method comprising:

[0026] S100: Obtain the parameter information of the copper plate of the mold;

[0027] Specifically, the mold is the key tool in horizontal continuous casting, and the copper plate is the main component of the mold.

[0028] The parameter information includes parameter information such as geometric parameters, material types, and preparation processes of the crystallizer copper plate, wherein the geometric parameters include geometric parameters such as narrow-side copper plates and broad-side copper plates; the material types include red copper, phosphor copper, Cu - Cr-Zr alloy, Cu-Ag alloy and other material types; the preparation process includes the chemical composition ratio of raw materials in the preparation process, preparation process steps and corresponding preparation process ...

Embodiment 2

[0085] Based on the same inventive concept as the method for optimizing the quality of mold copper plate based on thermal conductivity evaluation in the foregoing embodiment, such as Figure 4 As shown, the present application provides a mold copper plate quality optimization system based on thermal conductivity evaluation, wherein the system includes:

[0086] The first obtaining unit 11, the first obtaining unit 11 is used to obtain the parameter information of the copper plate of the mold;

[0087] The first processing unit 12, the first processing unit 12 is configured to perform partition processing on the mold copper plate through the mold copper plate parameter information, and obtain a plurality of block parameters;

[0088] The second obtaining unit 13, the second obtaining unit 13 is configured to obtain the thermal conductivity parameter set of the mold copper plate through the plurality of block parameters;

[0089] The third obtaining unit 14, the third obtaining...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com