Super-tough cable

A toughness and cable technology, applied in the field of ultra-strong toughness cables, can solve the problems of poor flexibility of metal fibers, poor cable flexibility, poor tensile resistance, etc., and achieve the effect of light weight, strong tensile performance, and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order for those skilled in the art to more clearly understand the purpose, technical solutions and advantages of the present invention, the present invention will be further described below with reference to the accompanying drawings and embodiments.

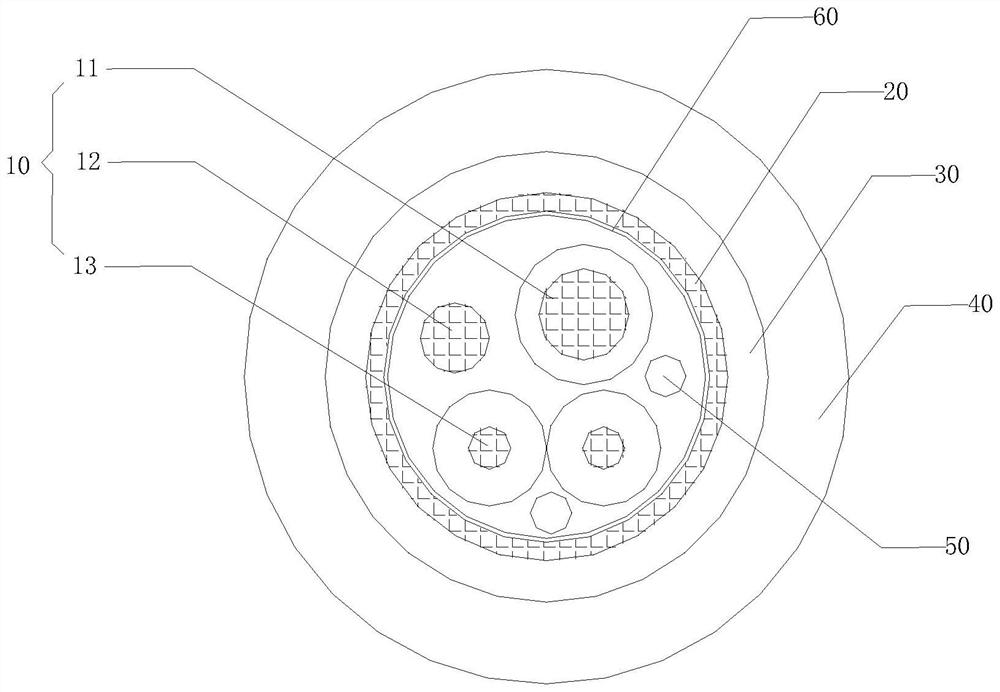

[0017] like figure 1 As shown, in some embodiments of the present invention, the super tough cable includes a transmission wire core 10, a shielding layer 20, a middle quilt 30 and an outer quilt 40, the transmission wire core 10 is arranged in the shielding layer 20, and the middle quilt is 30 is wrapped around the shielding layer 20, the outer covering 40 is wrapped around the inner covering 30, and the shielding layer 20 is braided by copper-plated Kevlar fibers.

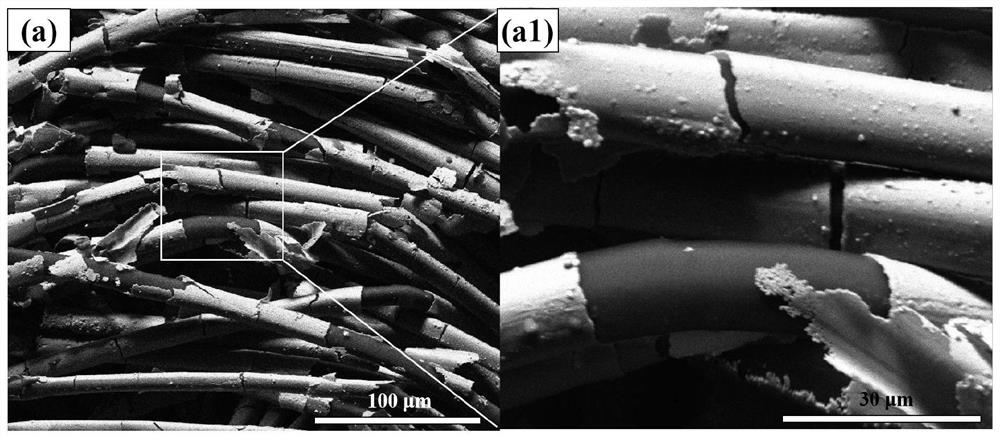

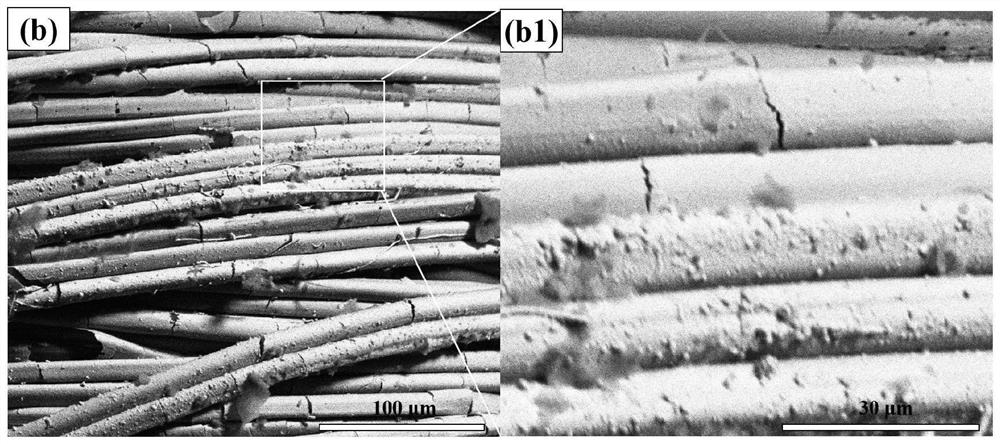

[0018] In this embodiment, electroless plating is used to perform copper plating on the surface of Kevlar fibers, so that the Kevlar fibers have metallic properties such as electrical conductivity, so as to obtain the copper-plated Kevlar fibers; it can b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com