Method for detecting initial position and rotating speed of rotor of permanent magnet synchronous motor at high rotating speed

A permanent magnet synchronous motor, rotor initial position technology, applied in the direction of electronic commutator, control generator, motor generator control, etc., can solve the problem of dependence, etc., achieve weakening influence, strong robustness and reliability, detection high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

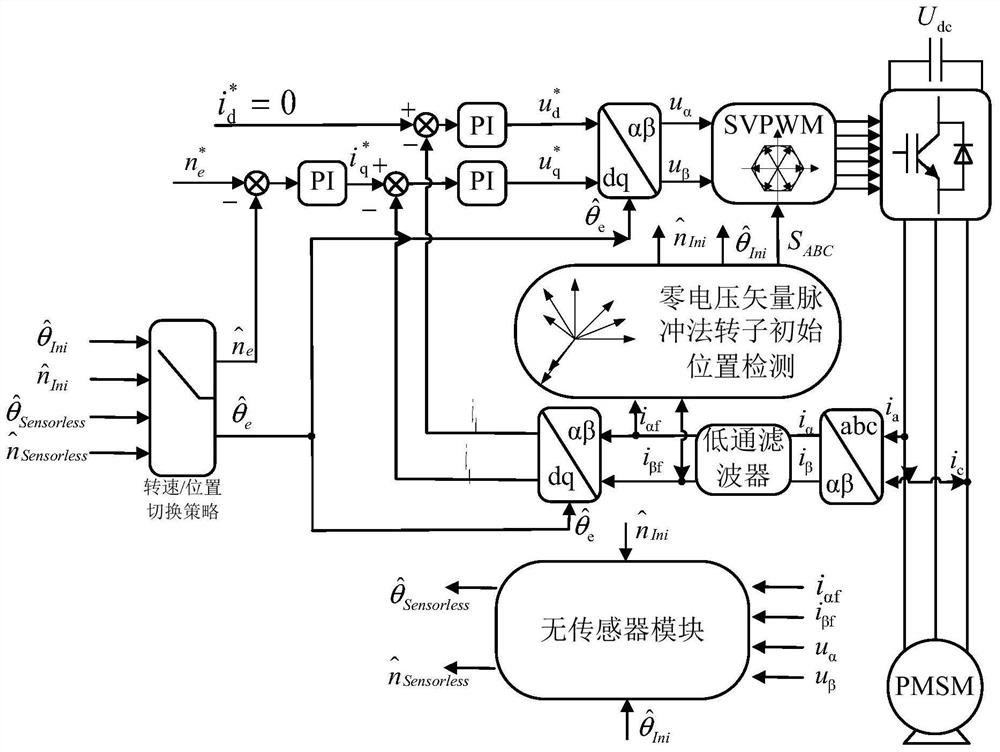

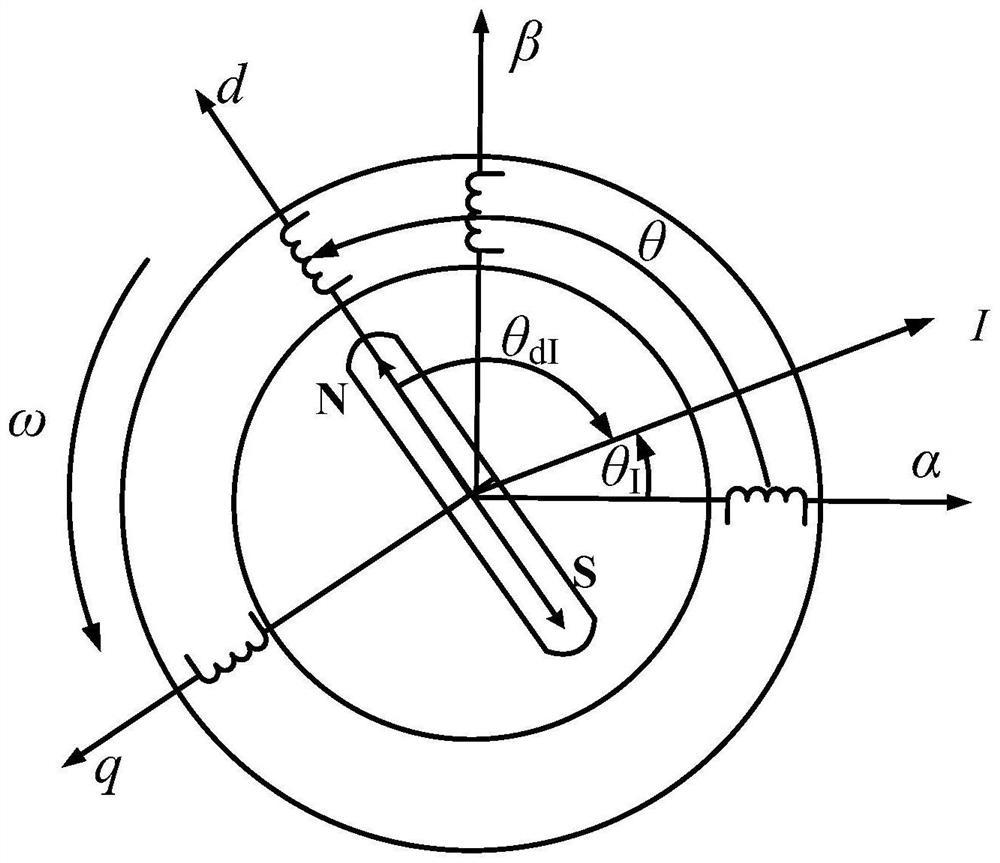

[0101] Specific implementation mode 1. Combination Figure 1 to Figure 7 As shown, the present invention provides a method for detecting the initial position and rotational speed of the rotor of a permanent magnet synchronous motor at a high rotational speed, which is characterized by comprising:

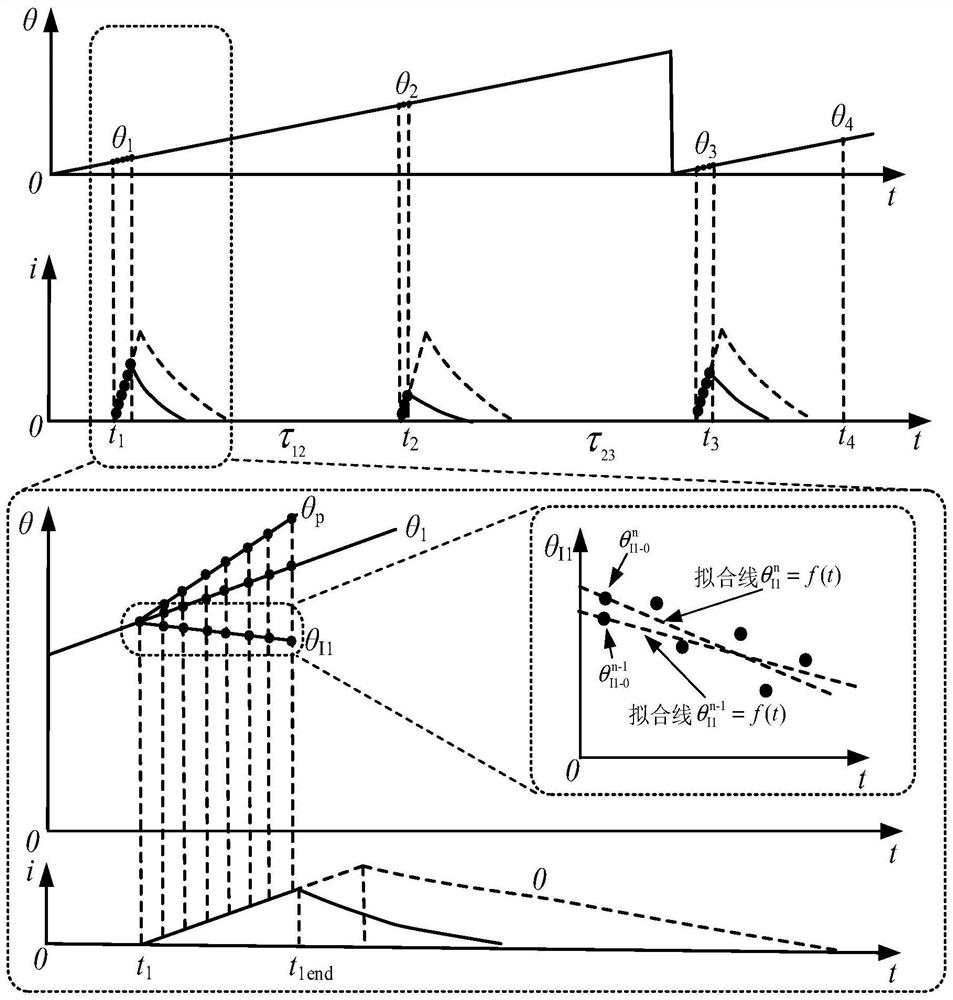

[0102] For the permanent magnet synchronous motor running at high speed, the mathematical model of the permanent magnet synchronous motor is designed; at the first selected time point t 1 , apply the first zero-voltage vector pulse to the mathematical model of the permanent magnet synchronous motor, and perform a current sampling in each PWM cycle during the application of the first zero-voltage vector pulse, and calculate the current vector according to the results of each current sampling. The current position angle in the coordinate system; perform linear fitting on the obtained current position angle to determine the zero current vector position angle θ at the zero point of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com