Aluminum alloy profile machining system and method

A technology of aluminum alloy profile and processing system, which is applied in the direction of metal processing equipment, manufacturing tools, grinding workpiece support, etc., can solve the problems of affecting the overall speed of aluminum profile processing, insufficient efficiency of equipment coordination, and reduced efficiency, so as to improve processing Efficiency, improved utilization efficiency, and improved adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

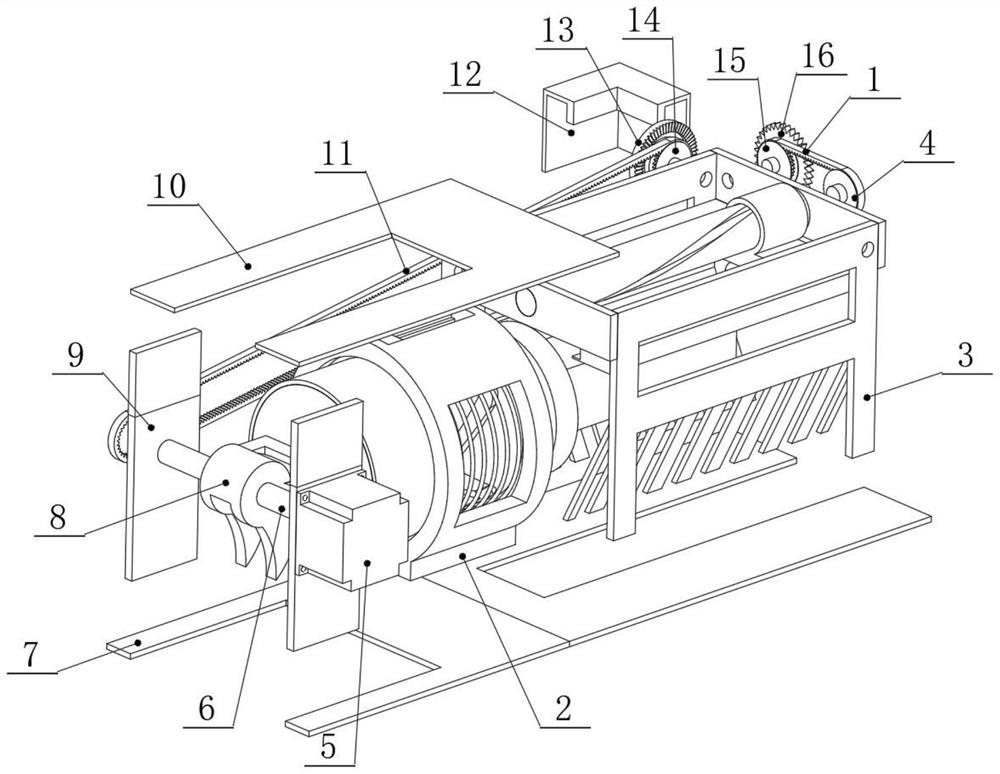

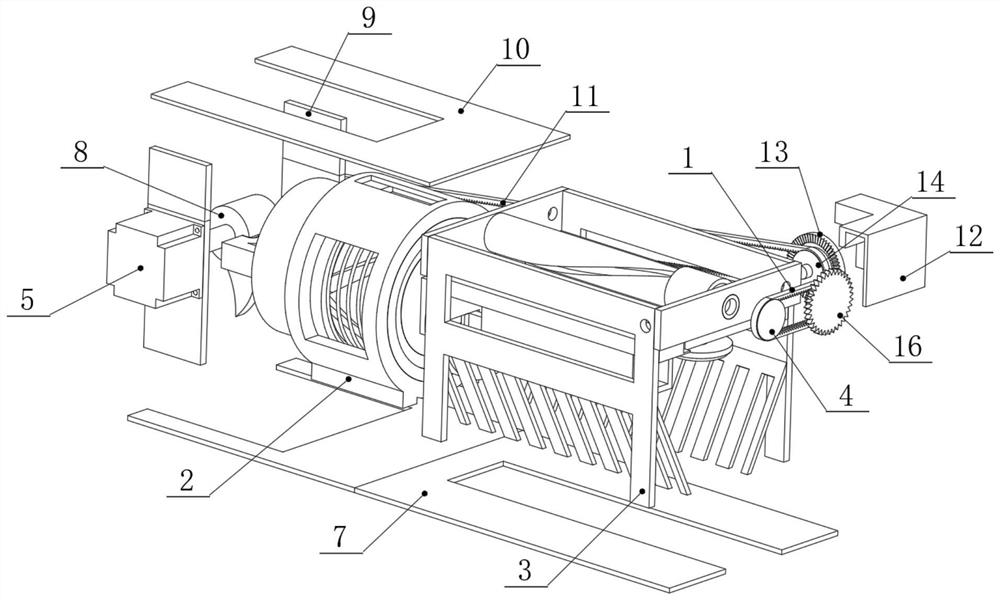

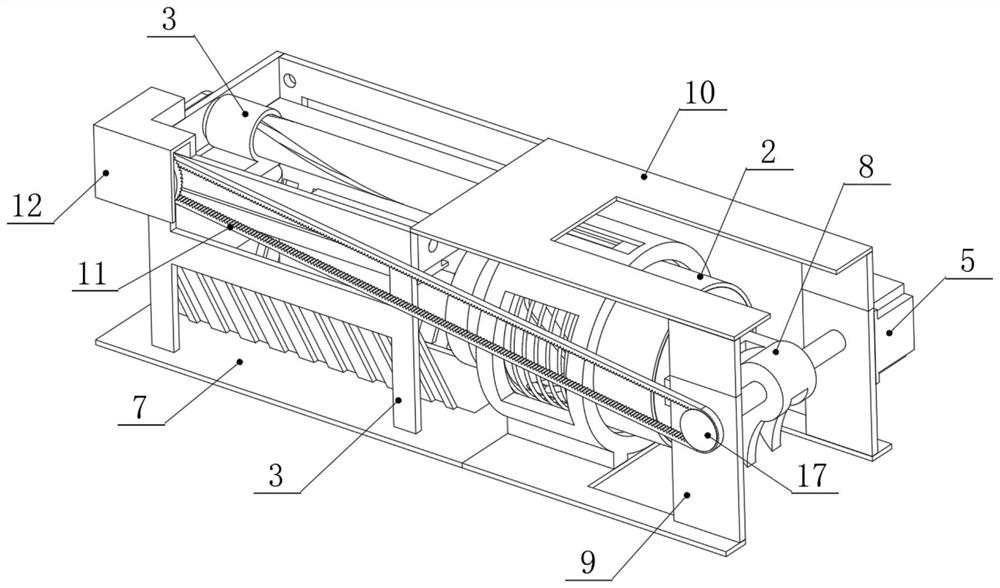

[0043] see Figure 1-13 , The present invention provides a technical solution: an aluminum alloy profile processing system and method, including a toothed belt 1, a circulating turning device 2, a processing device 3, a toothed pulley 4, a servo motor 5, a supporting guide shaft 6, a connection Bottom plate 7, connecting cam 8, fixed side plate 9, connecting top plate 10, transmission belt 11, protective card cover 12, connecting toothed plate 13, fixed pulley 14, supporting pulley 15, positioning gear 16 and guide pulley 17,

[0044] The upper end surface of the connection base plate 7 is symmetrically and fixedly installed with a fixed side plate 9 for support, and the servo motor 5 is fixedly installed at the center of the side end surface of the fixed side plate 9, and the side end surface of the servo motor 5 is fixedly connected with a support guide shaft 6 , and the connecting cam 8 is fixedly arranged at the center of the outer end face of the support guide shaft 6, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com