Amphiphilic antifouling active agent and preparation method thereof

An active agent and amphiphilic technology, which is applied in the field of hyperbranched amphiphilic antifouling active agents and their preparation, can solve the problems affecting the antifouling performance and loss of materials, and achieve the effect of meeting the needs of long-term antifouling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The specific technological process of the preparation method of the amphiphilic antifouling active agent involved in the present embodiment is:

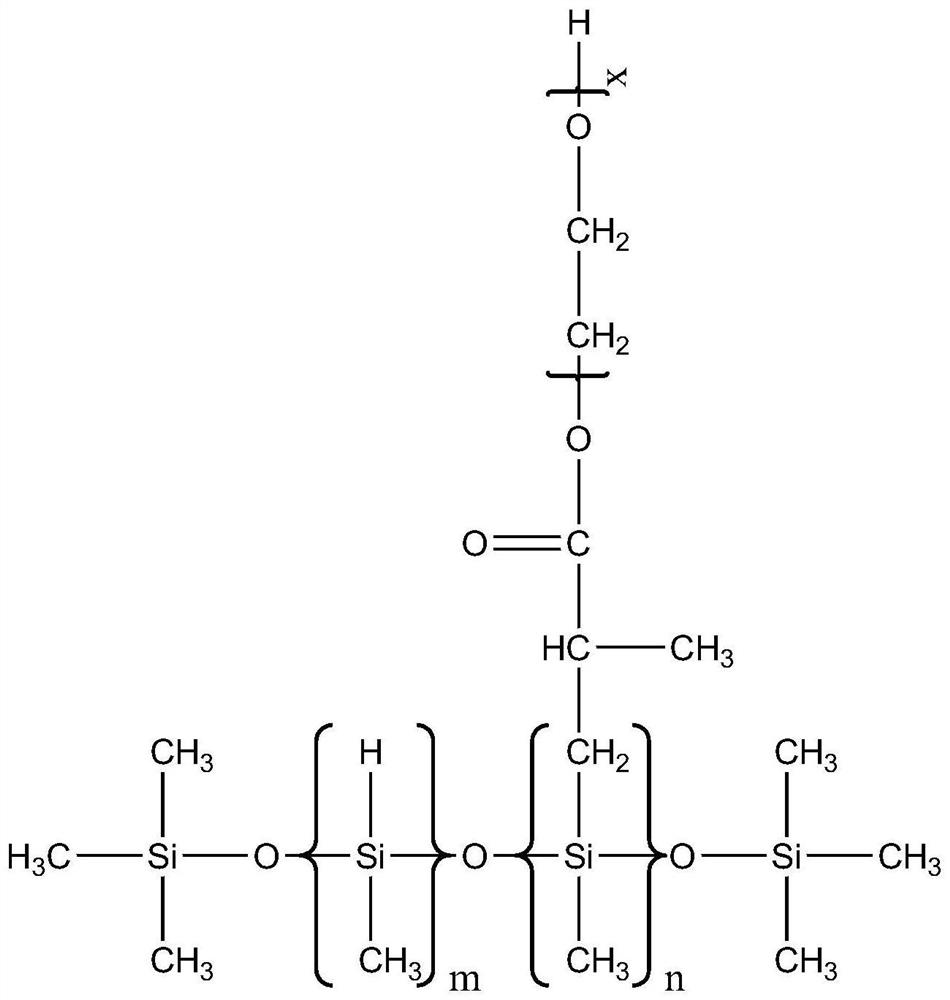

[0021] 8 parts by mass of hydrogen-containing silicone oil with a hydrogen content of 1.6% (mass percentage) and a viscosity of 20cp, 1 mass part of H 2 PtCl 2 ·6H 2 O catalyst and 200 parts by mass of cyclohexanone, then add 60 parts by mass of active double bond polyethylene glycol, the molar ratio of the polymer segments is 1:1, in a nitrogen atmosphere, at a temperature of 20 ℃ for 24h The hydrosilylation reaction of figure 1 HSO-PEG as shown.

Embodiment 2

[0023] The specific technological process of the preparation method of the amphiphilic antifouling active agent involved in the present embodiment is:

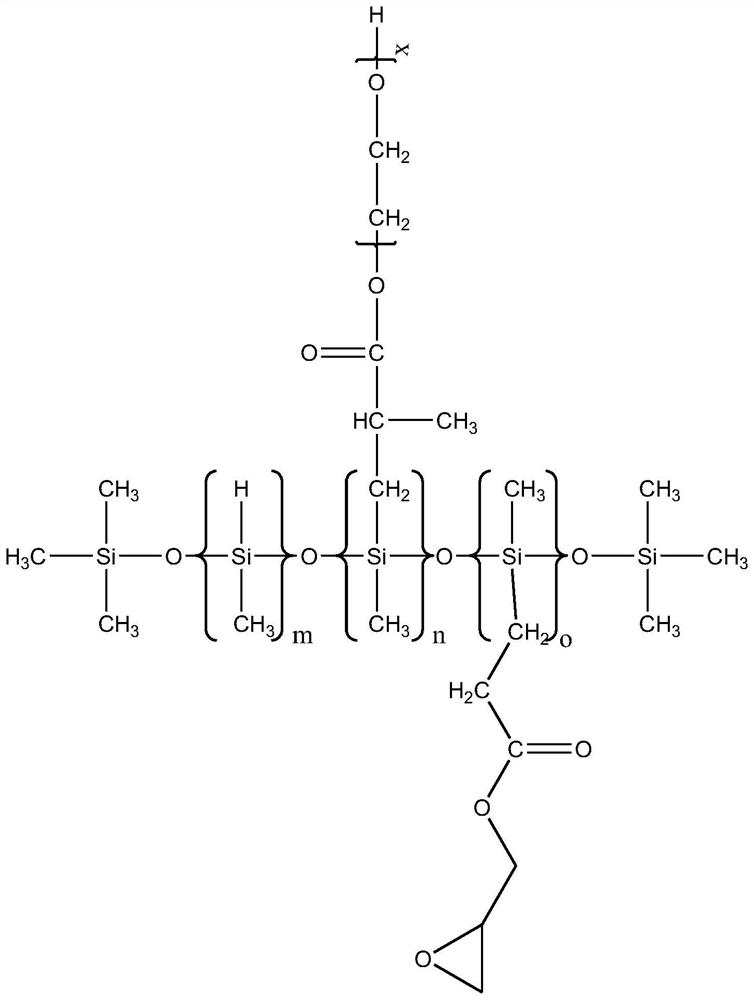

[0024] 12 parts by mass of hydrogen-containing silicone oil with a hydrogen content of 0.1% (mass percentage) and a viscosity of 5000cp, 5 parts by mass of Pt (dvs) catalyst, 100 parts by mass of methyl chloride, and 100 parts by mass of cyclohexanone were sequentially added to the reaction vessel , and then add 40 parts by mass of active double bond polyethylene glycol and 20 mass parts of active double bond glycidyl ester, the molar ratio of the polymer segment is 3:2:1, in a nitrogen atmosphere, at a temperature of 80 ℃. Carry out 1h hydrosilylation reaction, fully react to obtain such as figure 2 HSO-PEG-E as shown.

Embodiment 3

[0026] The specific technological process of the preparation method of the amphiphilic antifouling active agent involved in the present embodiment is:

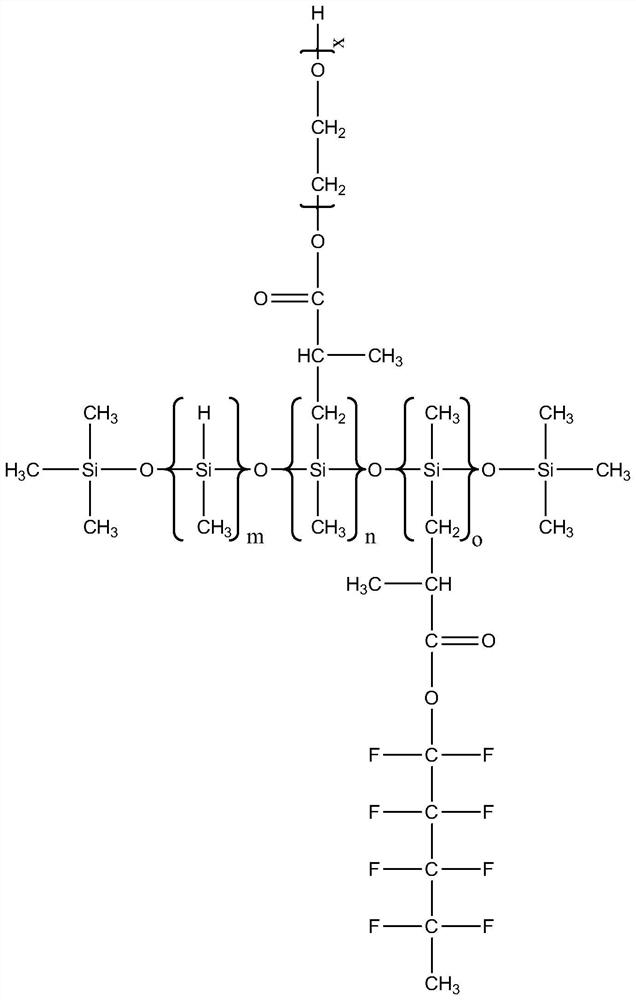

[0027] 10 parts by mass of hydrogen-containing silicone oil with a hydrogen content of 0.56% (mass percentage) and a viscosity of 200 cp, 4 parts by mass of Pd (Ph 3 P) 4 Catalyst, 100 parts by mass of dimethyl sulfoxide and 100 parts by mass of isopropanol, 40 parts by mass of active double bond polyethylene glycol and 20 mass parts of active double bond fluoroalkane, and the molar ratio of the polymer segment is 3: 2:1, in a nitrogen atmosphere, at a temperature of 60 ° C for 8h of hydrosilylation reaction, to obtain the following image 3 HSO-PEG-F shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com