Biodegradable materials, preparation method and usage

A biodegradable material and weight technology, applied in the field of biodegradable materials and their preparation and application, can solve the problems of poor solubility and rheology, unstable aqueous solution, difficult storage, etc., to achieve stable performance, easy to master, and process simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

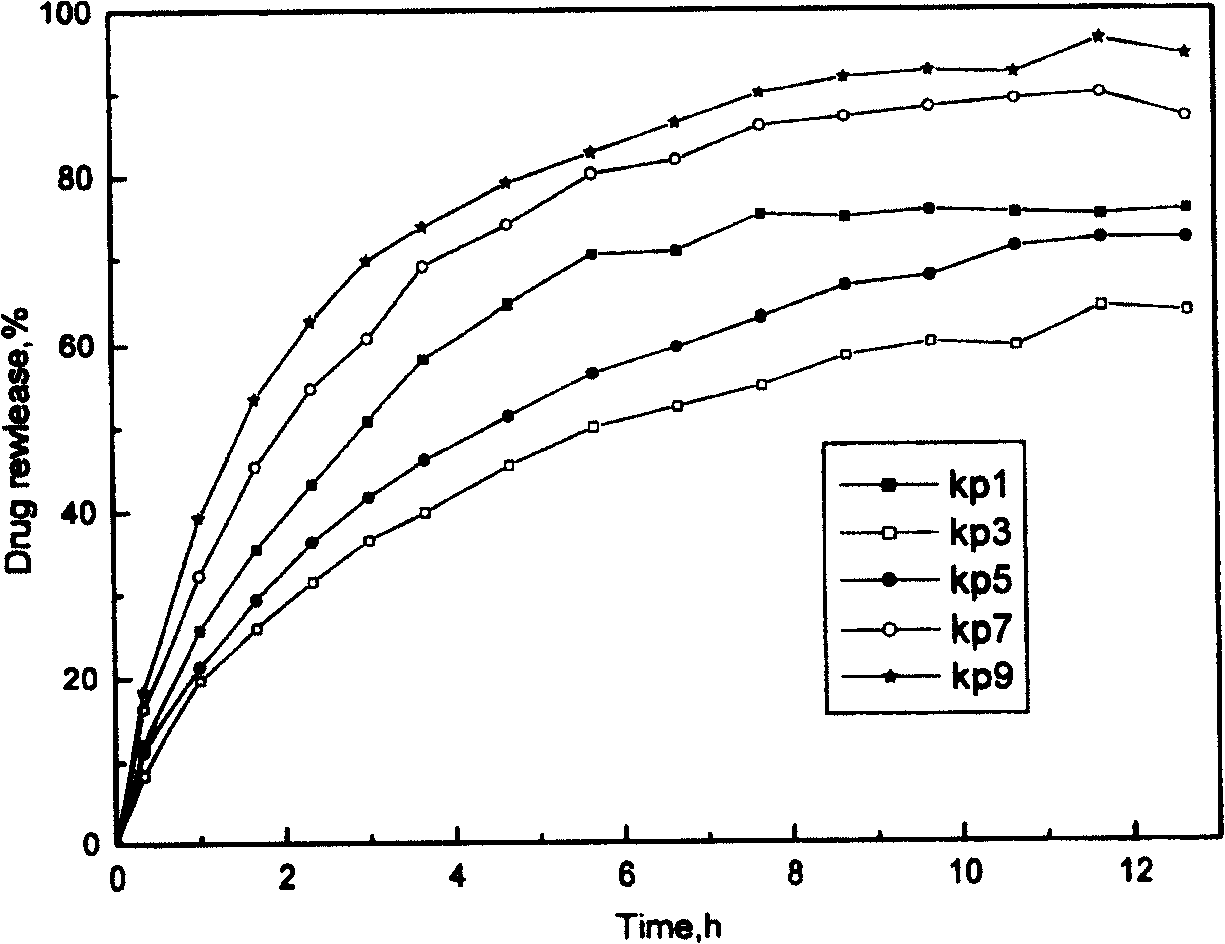

[0021] Weigh 1 g of konjac glucomannan and dissolve it in 200 ml of distilled water, stir at room temperature for 1 to 6 hours to form a uniform sol. Polyacrylic acid was made into 200 ml aqueous solution of 0.5% by weight. Mix 200 ml of konjac glucomannan sol, 200 ml of polyacrylic acid solution, and 0.1 g of plasticizer at room temperature for 1 to 6 hours to make a transparent glue. The transparent glue solution is stable and has good atomization property, and can be used as a film coating solution for drug cores.

Embodiment 2

[0023] Weigh 0.5 g of konjac glucomannan and dissolve it in 200 ml of distilled water, stir at room temperature for 1 to 6 hours to form a uniform sol. Polyacrylic acid was made into 200 ml aqueous solution of 0.75% by weight. Mix 200 ml of konjac glucomannan sol, 200 ml of polyacrylic acid solution, and 0.1 g of plasticizer at room temperature for 1 to 6 hours to make a transparent glue. Add chemical fertilizers and pesticides to the transparent glue, stir evenly, dry, crush or granulate slow-release products with an extrusion granulator. Or the drug sustained-release preparation is prepared by coating the core comprising the active pharmaceutical ingredient and the pharmaceutically acceptable excipient with a film coating solution.

Embodiment 3

[0025] Weigh 1.5 g of konjac glucomannan and dissolve it in 300 ml of distilled water, stir at room temperature for 1 to 6 hours to form a uniform sol. Polyacrylic acid is made into 100 ml aqueous solution of 0.5% by weight. Mix 300 ml of konjac glucomannan sol, 100 ml of polyacrylic acid solution, and 0.1 g of plasticizer at room temperature for 1 to 6 hours to make a transparent glue and make a seed coating agent to keep the seeds fresh. Mix 100 g of Legume seeds or grain seeds are mixed with it and air-dried at room temperature.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com