Preparation method of self-assembled microcapsule

A technology of microcapsules and self-assembly, which is applied in the field of preparation of self-assembled microcapsules, which can solve the problems that the production method cannot be produced in large quantities, and achieve the effects of easy industrial production, high yield, and good spheroidization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

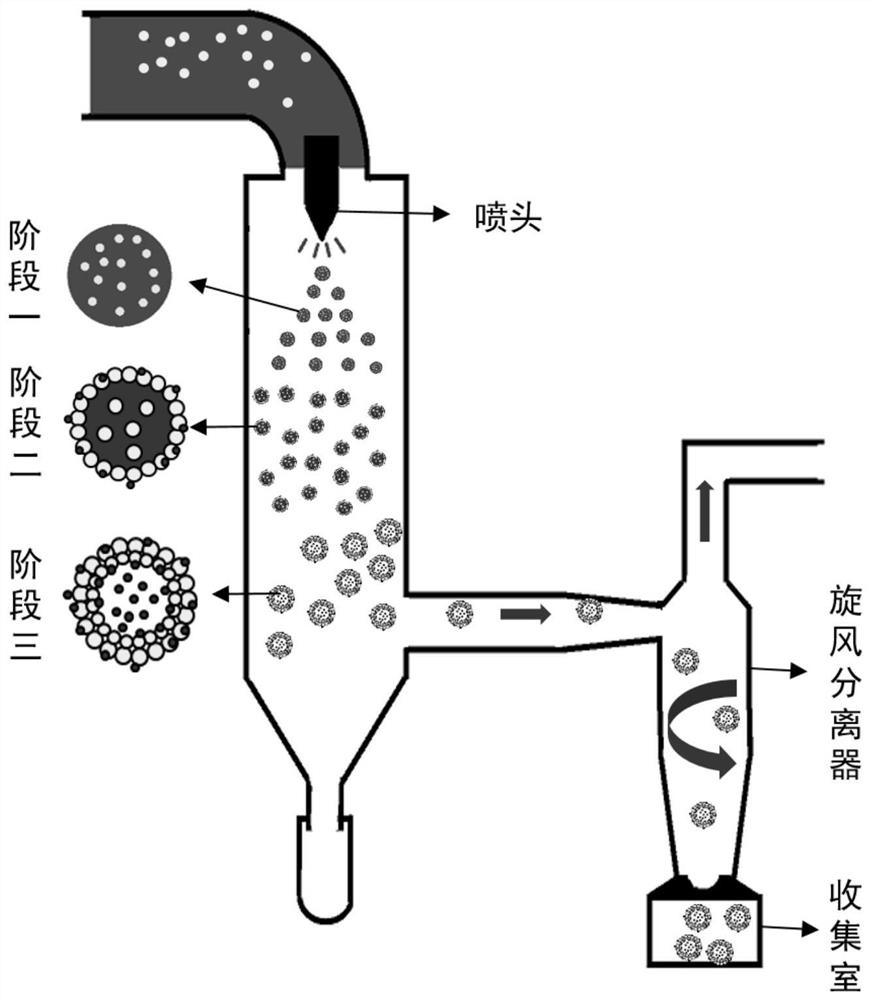

[0041] As an aspect of the present invention, a method for preparing self-assembled microcapsules, comprising the steps of:

[0042] S1. Preparation of nano-polymer capsule wall materials by polymerization

[0043]S1-1. Prepare polymer colloid particles by means of emulsion polymerization: Introduce nitrogen into the reactor in advance to eliminate oxygen, add half of the amount of polymerized monomer and water, start stirring, the stirring speed is 200-400rpm, add triggering agent and emulsifier, carry out the polymerization reaction, the polymerization temperature is 50-100 ℃, add the other half of the polymerized monomer after stirring for 15-25 minutes, and obtain the polymer colloidal particles after the reaction is complete; in this step, the polymerized monomer is divided into two additions Carrying out the polymerization reaction instead of adding the polymerized monomer at one time, the purpose is to make the particle size of the produced particles more uniform;

[0...

Embodiment 1

[0057] A kind of preparation method of self-assembled microcapsule

[0058] Step 1: Preparation of capsule wall material colloidal particles

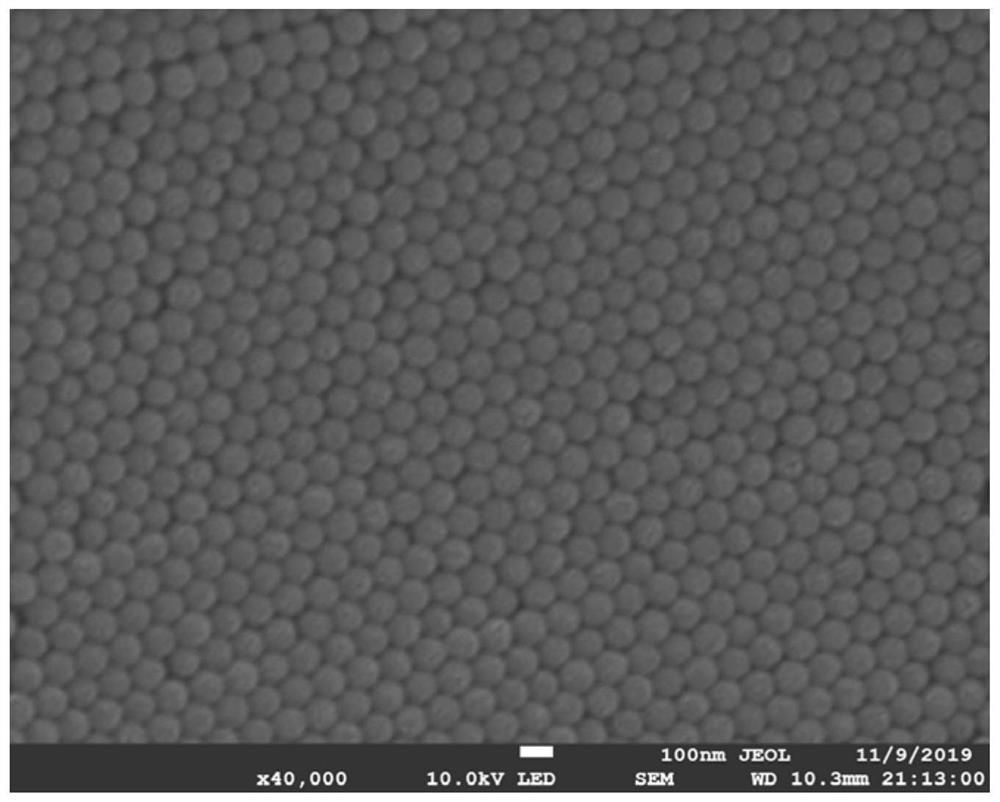

[0059] First, pass nitrogen gas through a 500mL four-neck flask for 20min, and the temperature of the water bath is 85°C. Add 50mL of distilled water, 8g of styrene, 4.375g of butyl acrylate and 0.125g of acrylic acid, turn on the stirring paddle at a speed of 400r / min, stir for 20min, then add 0.1g of SDS (sodium dodecyl sulfate) and KPS (potassium persulfate) 0.1g, after reacting for 20min, add distilled water 50mL, styrene 8g, butyl acrylate 4.375g and acrylic acid 0.125g, react for 10h. figure 2 The scanning electron microscope image of the synthesized colloidal particles shows that the particle size of the colloidal particles of the capsule wall material is about 80nm;

[0060] Step 2: Adjustment of Colloidal Particles of Capsule Wall Material

[0061] Take out the colloidal particle dispersion of the capsule wall material and ...

Embodiment 2

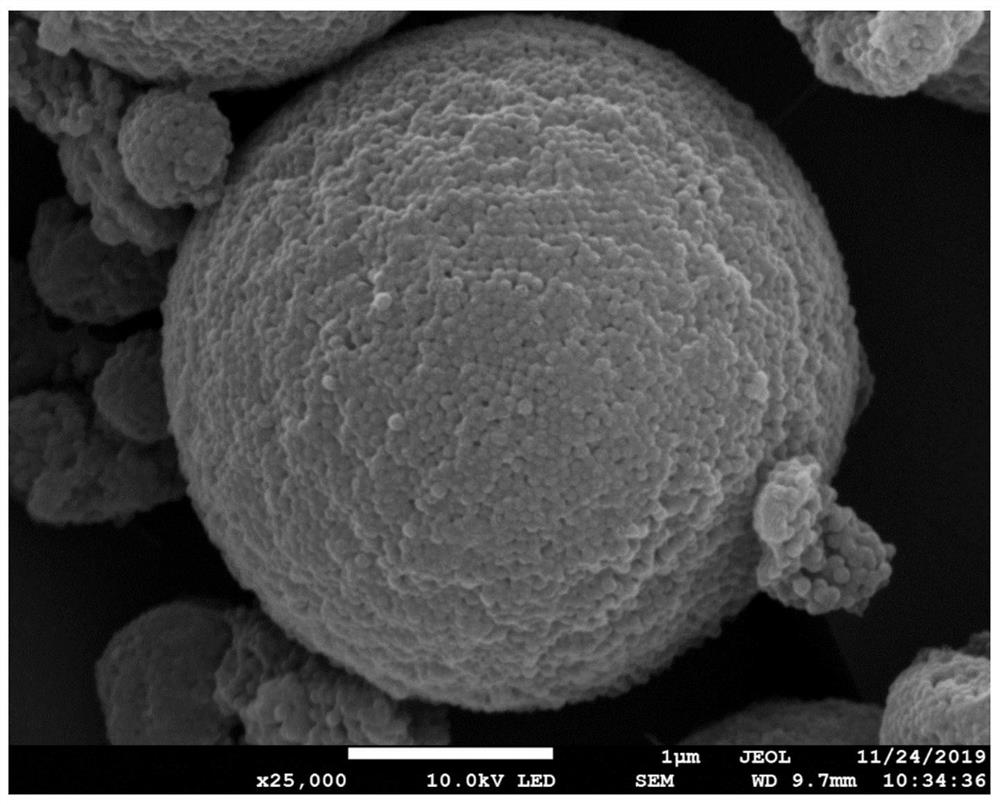

[0066] A kind of preparation method of self-assembled microcapsule embedding Congo red dye

[0067] Step 1: Preparation of capsule wall material colloidal particles

[0068] First, pass nitrogen gas through a 500mL four-neck flask for 20min, and the temperature of the water bath is 85°C. Add 50mL of distilled water, 8g of styrene, 4.375g of butyl acrylate and 0.125g of acrylic acid, turn on the stirring paddle at a speed of 400r / min, stir for 20min, then add 0.1g of SDS (sodium dodecyl sulfate) and KPS (potassium persulfate) 0.1g, react for 20min, then add distilled water 50mL, styrene 8g, butyl acrylate 4.375g and acrylic acid 0.125g, react for 10h;

[0069] Step 2: Adjustment of Colloidal Particles of Capsule Wall Material

[0070] The colloidal particle dispersion was taken out and dialyzed with a dialysis bag for more than 3 days. Take a sample and measure its solid content, add distilled water, adjust the solid content of the colloidal particle dispersion to 4wt%, add ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Solid content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com