Activated carbon fiber low-temperature pre-oxidation equipment

An activated carbon fiber and low temperature technology, which is applied in the field of activated carbon fiber low temperature pre-oxygenation equipment, can solve problems such as increased temperature, affecting product quality, and affecting the processing environment, so as to improve thermal insulation performance, avoid heat leakage, and improve heat exchange efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

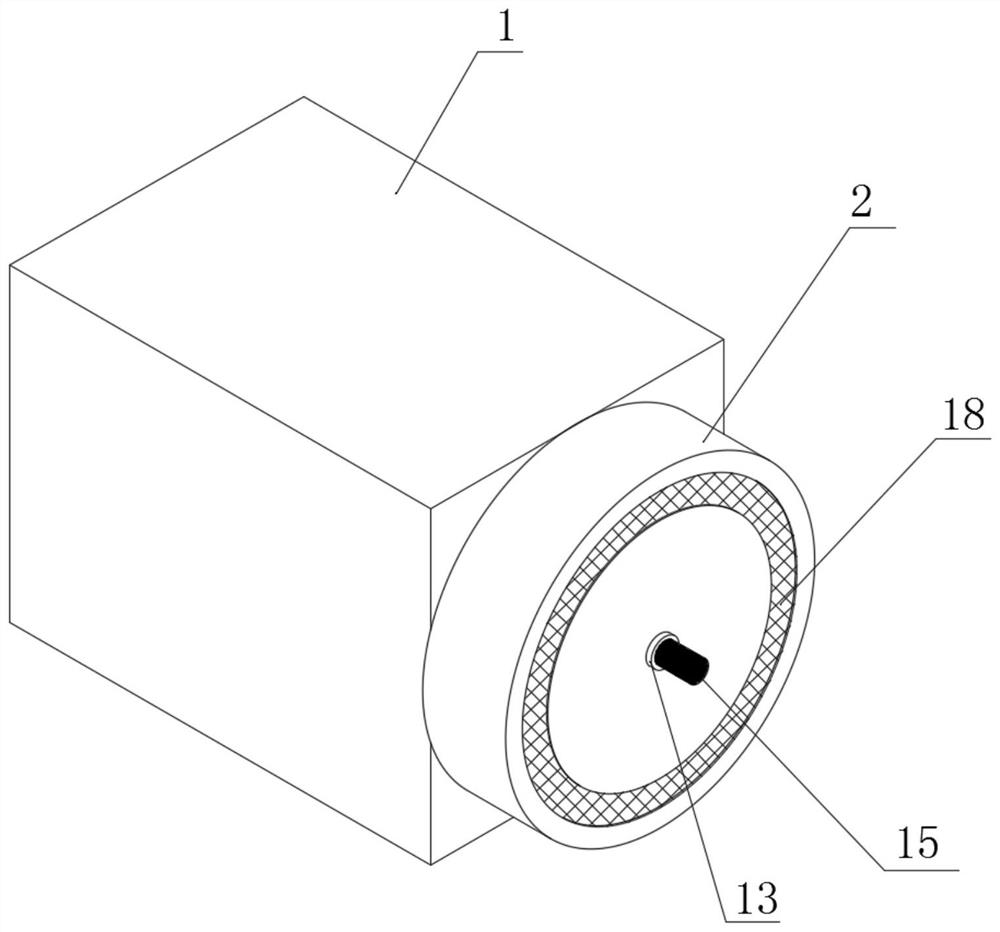

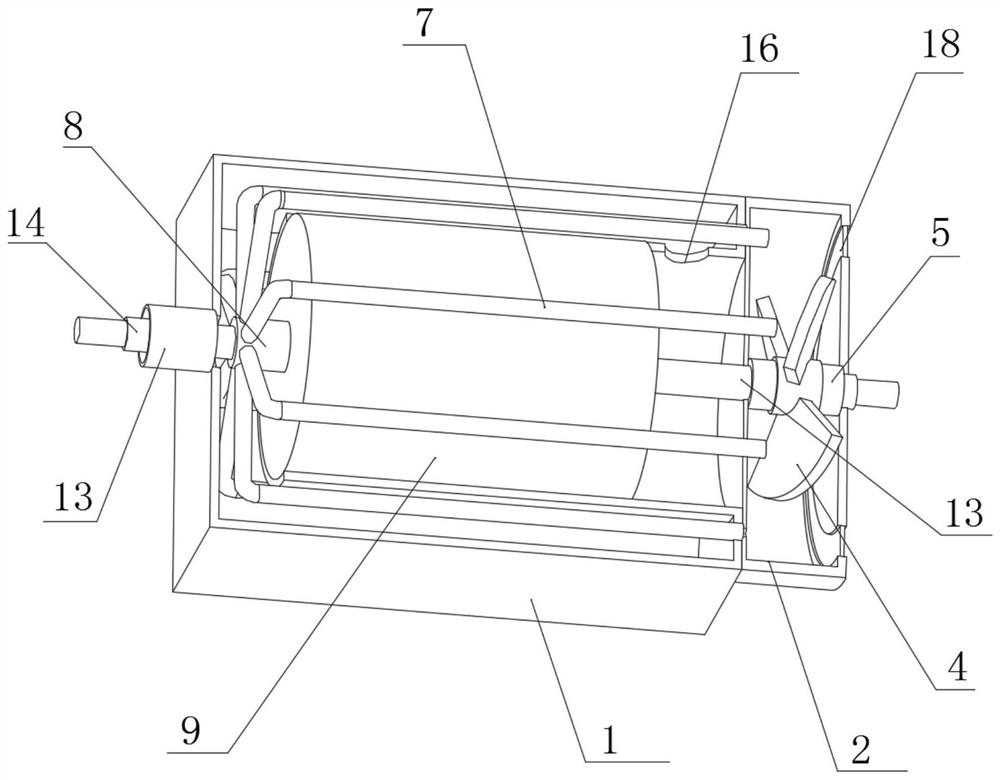

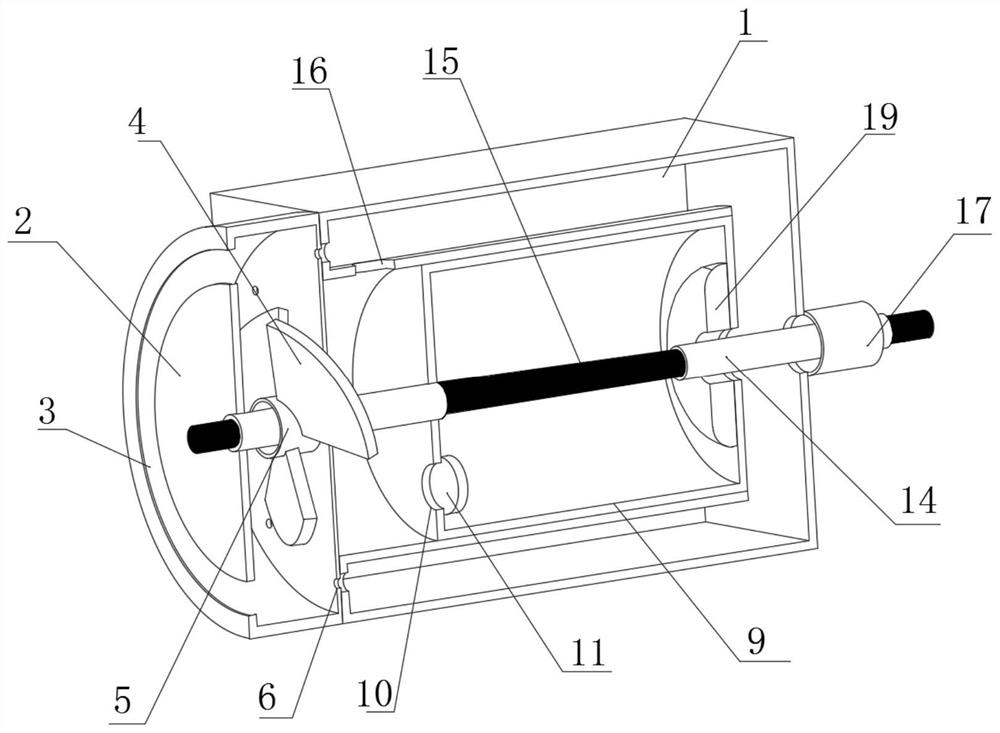

[0023] refer to Figure 1-4 , an activated carbon fiber low-temperature pre-oxygenation equipment, including a processing box 1 and a pre-oxygen box 9, wherein the bottom of the processing box 1 is provided with a fixed table, which is not marked in the figure, so that when in use, the upper and lower positions in the device can be determined, The side wall of the processing box 1 is fixedly provided with a bellows 2, and the side of the bellows 2 away from the processing box 1 is provided with an air inlet 3, and a negative pressure impeller 4 is arranged inside the bellows 2, and the rotation center of the negative pressure impeller 4 is fixedly connected with a rotating shaft 5. , the interior of the pre-oxygen box 9 is provided with a heating table 19, the processing box 1 is provided with a waste heat insulation structure, the rotating shaft 5 is connected with a transmission structure for processing carbon fiber bundles, the inner wall of the processing box 1 is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com