Combined system floor system and construction method thereof

A construction method and system technology, which can be applied in the treatment of floors, building materials, structural elements, etc., can solve problems such as water leakage, and achieve the effect of suppressing floor cracks, avoiding hidden dangers of water seepage, and effectively bearing loads.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

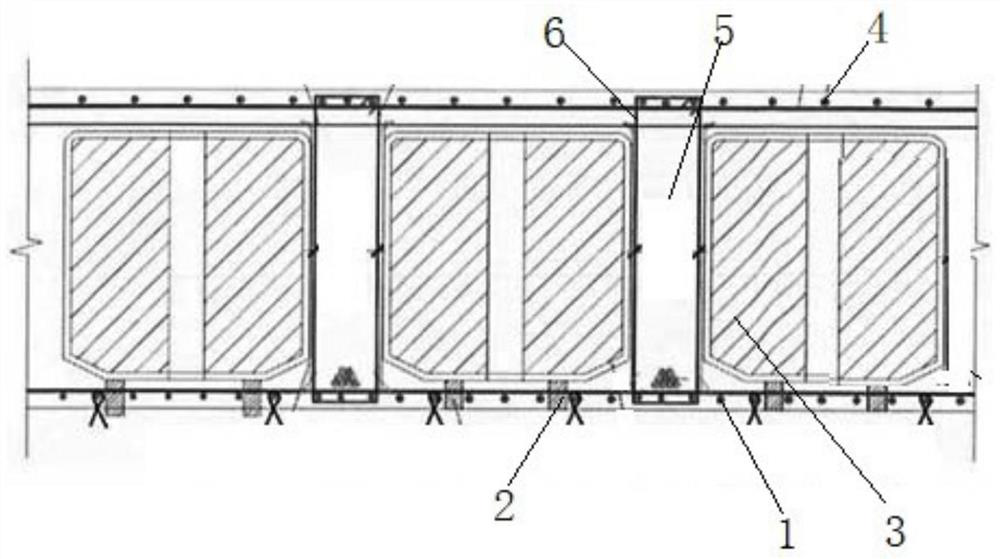

[0043] In order to solve the above problems, the present embodiment discloses a combined system floor, including: bottom steel bars 1 , stirrup steel bars 2 , box body members 3 and upper-layer steel bars 4 . Among them, the actual number of base steel bars 1, stirrup steel bars 2, box members 3 and upper steel bars 4 is determined according to the project requirements.

[0044] like figure 1 As shown in the figure, the bottom steel bar 1 is laid in the formwork as required; the stirrup steel bar 2 is arranged on the bottom plate steel bar 1. The box member 3 is laid on the stirrup steel bar 2 according to the engineering drawing. When laying the box member 3, it is necessary to handle it with care, and lay it in strict accordance with the detailed drawings. In the specific operation, it is recommended to first pull the wires to complete the arrangement of a row of boxes in the vertical and horizontal directions, and then align the left and right sides of the remaining boxes ...

Embodiment 2

[0057] Based on the above-described embodiment, the present embodiment discloses a construction method of a combined system floor, specifically comprising the following steps:

[0058] In order to effectively control the floating of the BDF box during the concrete pouring process, the anti-floating iron wire should be fixed after the steel bars on the bottom plate are laid and bound and the protective layer cushions are placed. Combined with the box size of this project, 12# iron wire should be used to fasten the intersection of the steel bars on the bottom plate with a spacing of no more than 600mm, and then anchor it on the supporting steel pipe, wooden square or formwork after passing through the bottom plate formwork.

[0059] After the square stool is placed, the box is laid out according to the layout plan. In the process of laying the box, it should be handled with care, and laid in strict accordance with the detailed drawings. In the specific operation, it is recommen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com