Ground source assisted waste heat gradient utilization water source heat pump hot water system

A water source heat pump and hot water system technology, which is applied in the field of high-efficiency building energy conservation, can solve problems such as abnormal use, increased overall operating energy consumption of equipment, and increased costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

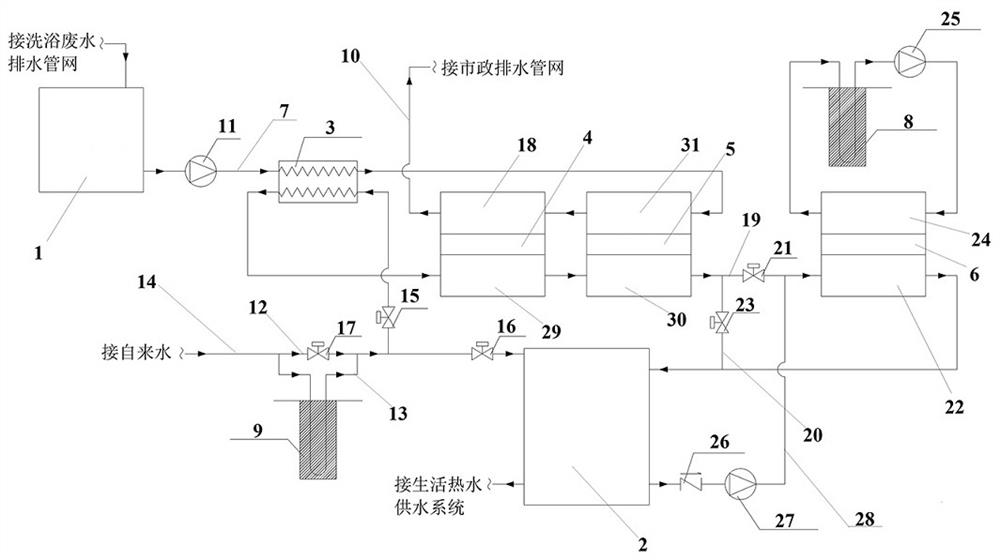

[0025] The present invention will now be further described with reference to specific embodiments and accompanying drawings.

[0026] like figure 1 It can be seen that the present invention discloses a ground source-assisted waste heat cascade utilization water source heat pump hot water system, including a waste water tank 1, a hot water tank 2, a clean water inlet pipe 14, a heat exchanger 3, a heat pump A4, a heat pump B5, a heat pump C6, Bathing waste water inlet pipe 7, buried pipe A8, buried pipe B9, hot water output pipe and waste water discharge pipe 10; waste water tank 1 is connected with bath waste water inlet pipe 7, bath waste water inlet pipe 7 is provided with waste water pump 11, bathing wastewater The other end of the waste water inlet pipe 7 is connected to the heat exchanger 3 . It also includes a clean water inlet pipe A12 and a clean water inlet pipe B13. After the two ends meet, they are connected to the clean water inlet pipe 14. After the other ends me...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap