Buffering and heat-insulating composite layer, preparation method thereof, battery and power utilization device

A technology of electrical devices and composite layers, which is applied in secondary batteries, battery pack components, circuits, etc., can solve problems such as powder dropping, heat insulation performance and poor mechanical properties, so as to avoid pollution and damage, and prevent heat loss. Spread effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

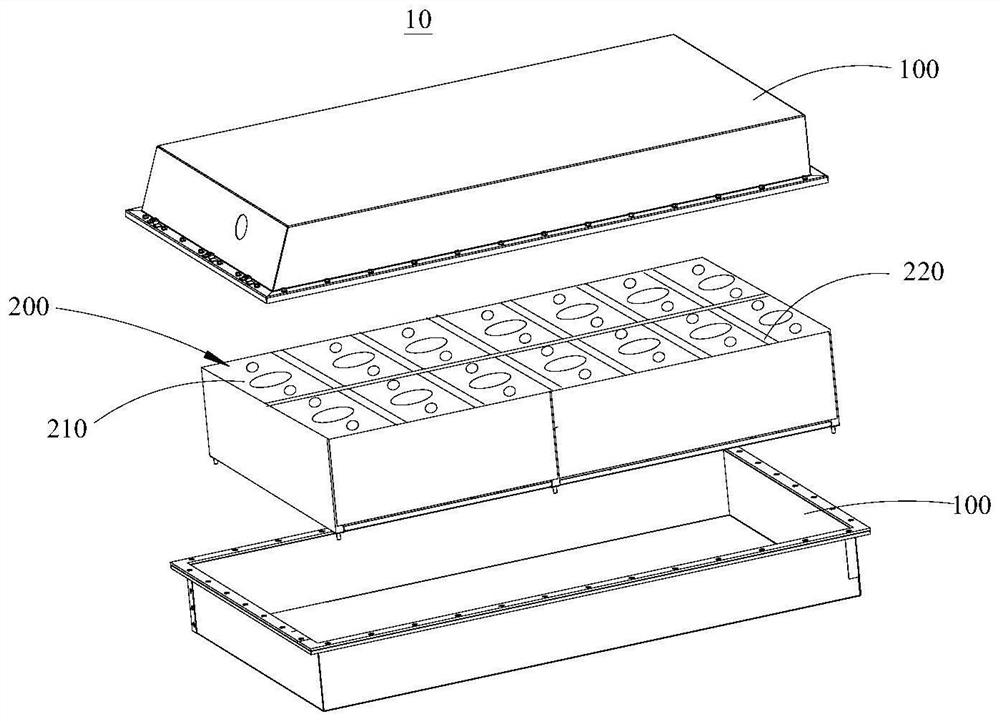

[0038] see figure 1 , the embodiment of the present application provides a battery 10 , wherein the battery 10 includes a box body 100 and a battery module 200 , and the battery module 200 is accommodated in the box body 100 . The box body 100 is used to provide an accommodation space for the battery module 200 , and the box body 100 may adopt various shapes, such as a cylinder, a rectangular parallelepiped, and the like.

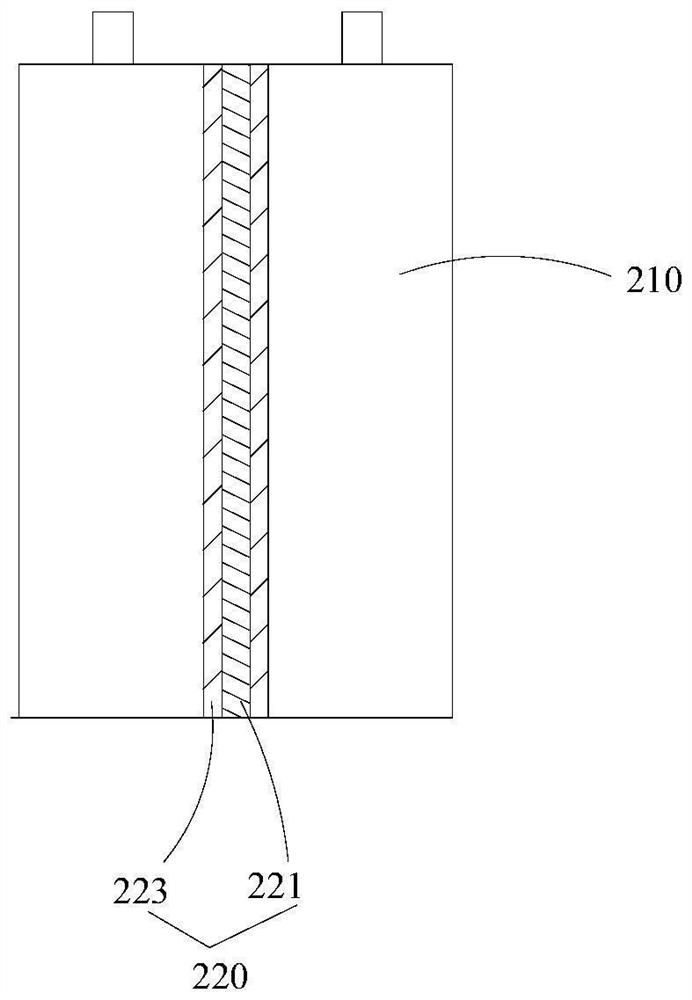

[0039] see figure 1 as well as figure 2 , the battery module 200 provided by the embodiment of the present application includes: a plurality of single cells 210 and a buffer and heat insulation composite layer 220, wherein the plurality of single cells 210 are stacked in sequence along the arrangement direction; the buffer heat insulation composite layer 220 is arranged adjacent to between the two single cells 210.

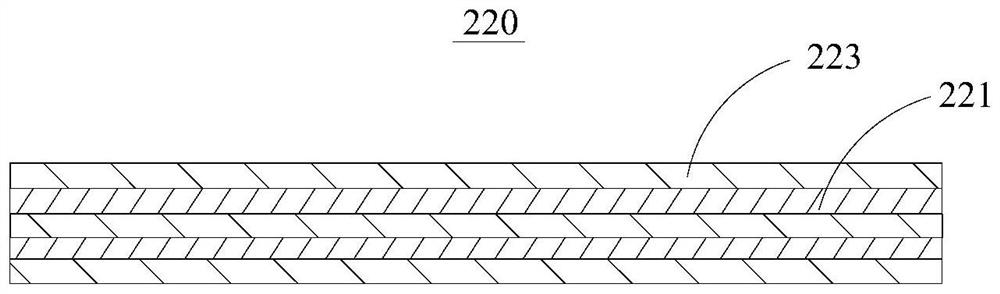

[0040] The buffer and thermal insulation composite layer 220 includes at least one aerogel layer 221 and multiple layers of geopolymer lay...

Embodiment 2

[0074] The fly ash was pretreated in a planetary ball mill, and ball milled for 20 min at 350 rpm to obtain a powder with a D99 of 60 mm for use, and the alkali activator was water glass (Na 2 O nH 2 O) and NaOH as alkali activators, the water glass modulus was adjusted to 1.5 by adding NaOH and water, and the water-to-binder ratio was 0.3.

[0075] Put water glass, aluminum silicate fiber, and fly ash powder into a container in a mass ratio of 1:2:7, and use a revolution and auto-rotating mixer to disperse. 2 min to obtain the slurry; the slurry was uniformly scraped onto the surface of the aluminum silicate fiber reinforced silica aerogel with a thickness of 2 mm, and the thickness of the slurry on both sides was controlled at 1 mm. After being placed at room temperature (25 ° C) for 4 days, A buffer thermal insulation composite layer is obtained.

Embodiment 3

[0077] The fly ash was pretreated in a planetary ball mill, and ball milled for 20 min at 350 rpm to obtain a powder with a D99 of 60 mm for use, and the alkali activator was water glass (Na 2 O nH 2 O) and NaOH as alkali activators, the water glass modulus was adjusted to 1.5 by adding NaOH and water, and the water-to-binder ratio was 0.3.

[0078] The water glass and the fly ash powder are put into a container in a mass ratio of 1:9, and dispersed by a revolution and rotation mixer. The dispersion conditions are as follows: 1600 rpm revolution, 600 rpm, and 10 minutes of dispersion, and then deaerated for 2 minutes to obtain a composite slurry; The slurry was uniformly scraped onto the surface of the aluminum silicate fiber reinforced silica aerogel with a thickness of 2 mm, and the thickness of the slurry on both sides was controlled at 1 mm. After being placed at room temperature (25 ° C) for 4 days, the buffer insulation was obtained composite layer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com