Integrated electro-optical flexible circuit board

A technology of integrating electro-optic and circuit boards, applied in the direction of hierarchical auxiliary printed circuit boards, dielectric properties, printed circuits, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

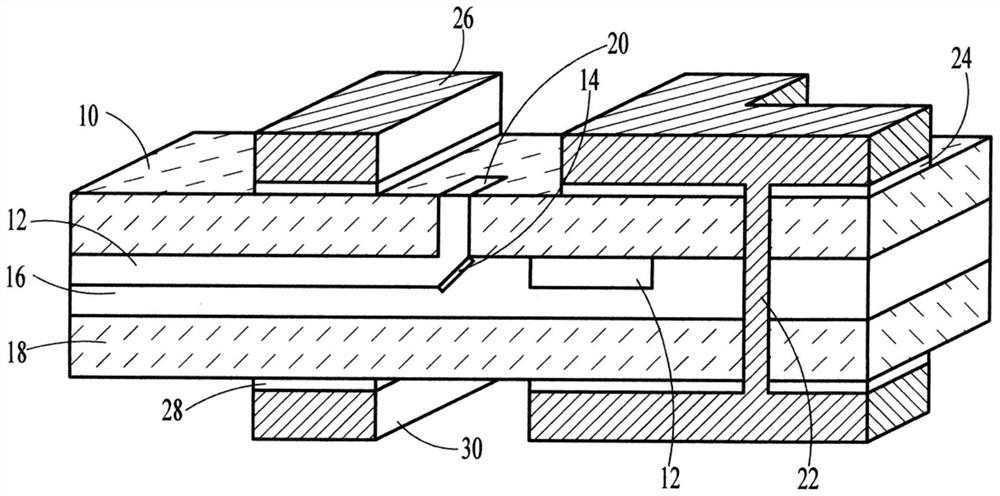

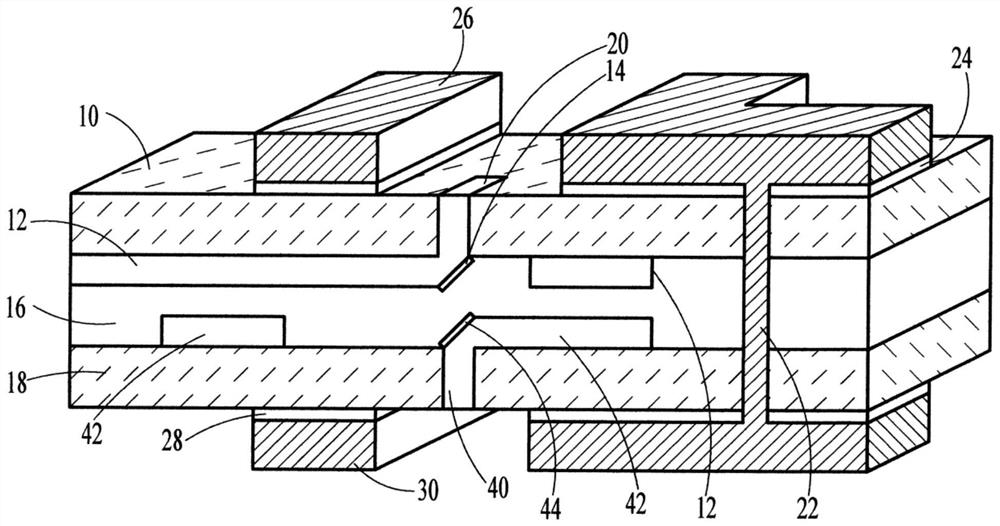

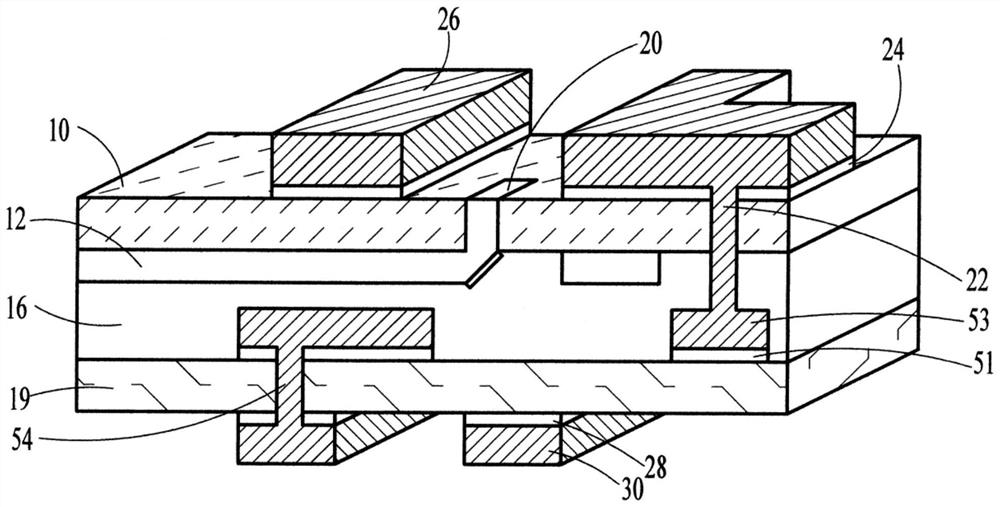

[0020] The invention discloses various versions of integrated electro-optical flexible circuit board (EOFCB). The functions of these circuit boards include electronic and optical circuits, flexible electronic components, and glass materials. Electronic circuits typically have low speed signals and are often used for power distribution with lower circuit density. Optical circuits typically have high-speed signals and high circuit density. Flexible electronics have a small profile and are relatively inconspicuous, they generally have a high wiring density and are foldable and bendable. Glass materials have smooth, transparent surfaces and low dielectric signal loss.

[0021] The concept of the present invention is to embed an optical circuit on a flexible electronic circuit, and the fabrication will take place on the same glass plate used for the flexible electronic circuit to provide better isolation characteristics. The present invention uses an optical adhesive to form a c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com