Cooling device and cooling method for fertilizer production

A cooling device and fertilizer technology, applied in chemical instruments and methods, mixers with rotating stirring devices, transportation and packaging, etc., can solve the problems of reducing fertilizer use efficiency, reducing device work efficiency, and incapable of material classification and transmission, etc., to achieve Reduce work efficiency, improve efficiency, and avoid the effects of chemical changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

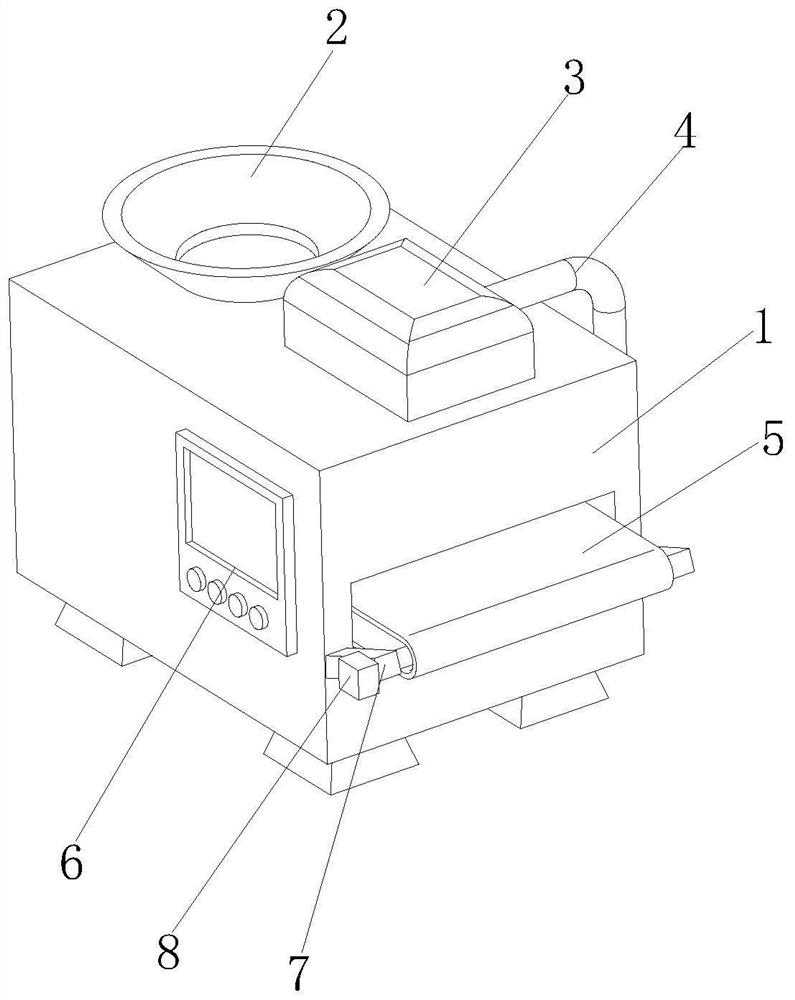

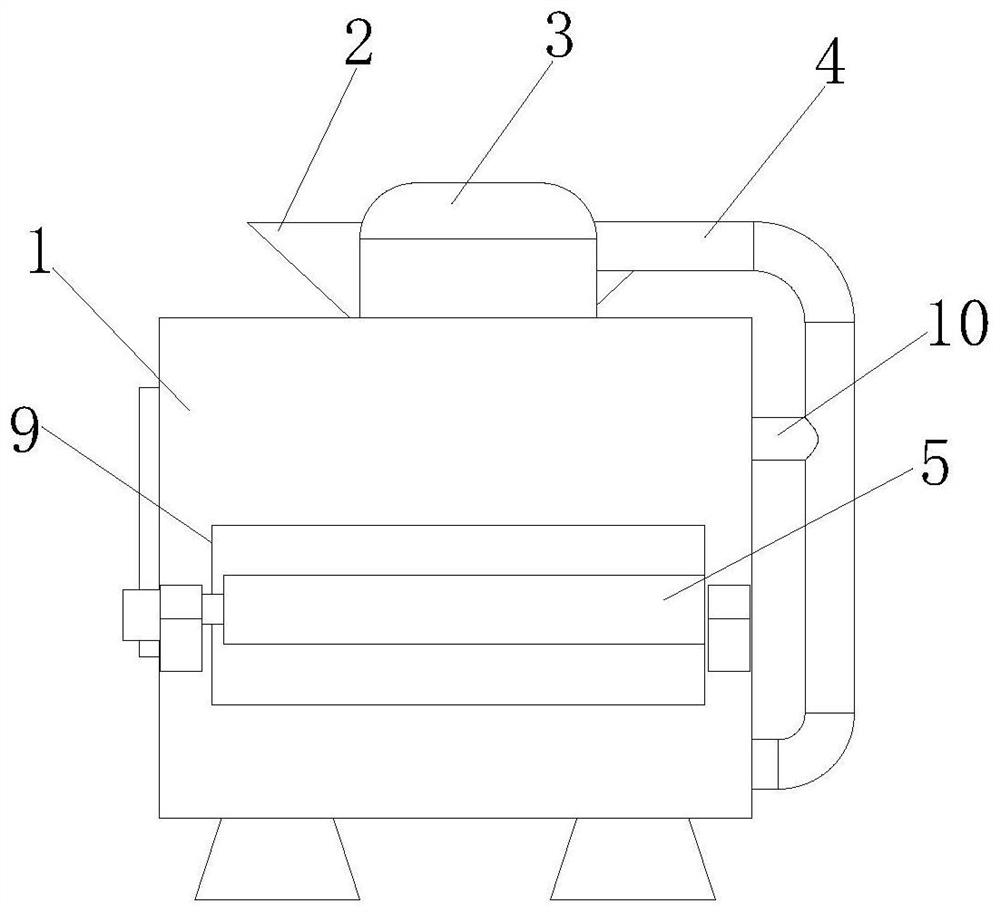

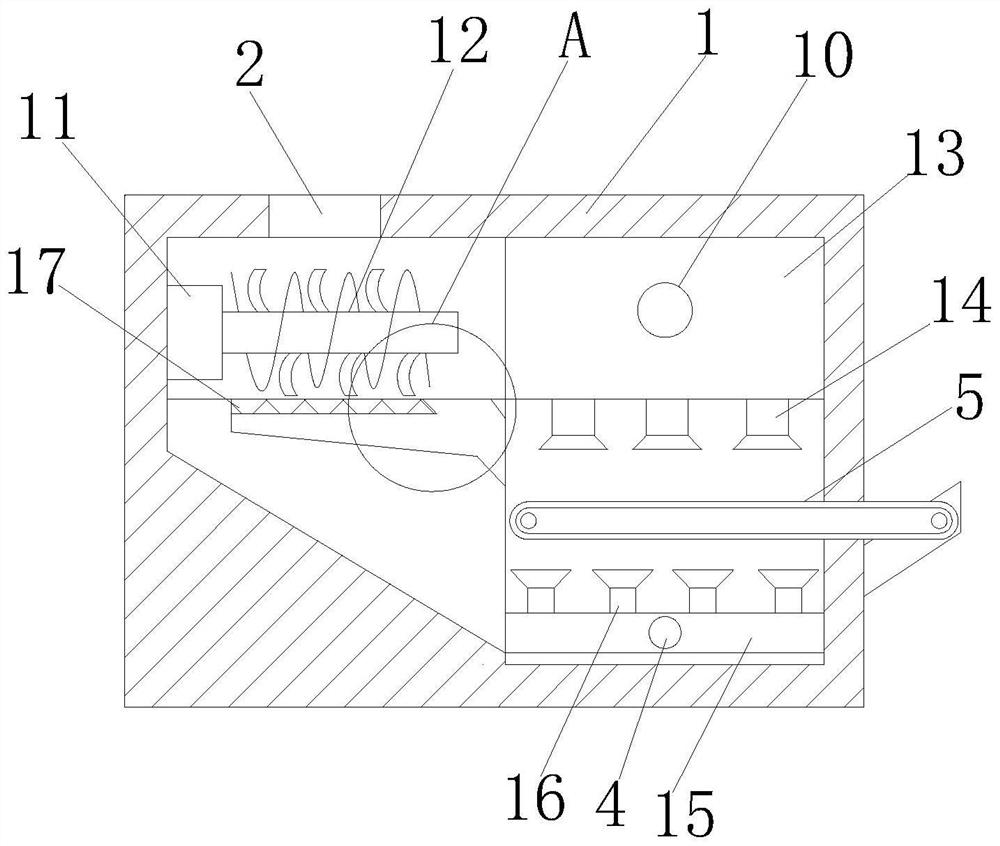

[0024] like Figure 1-5 As shown, the present invention provides a cooling device and a cooling method for fertilizer production, comprising a cooling device main body 1, the upper end of the cooling device main body 1 is fixedly connected with a feeding port 2, and the front surface of the cooling device main body 1 is fixedly connected with a control element 6 , a cooling device 3 is fixedly installed on the upper end of the cooling device main body 1, a conveying pipe 4 is fixedly connected to the back of the cooling device 3, a support rod 7 is fixedly connected to the right end of the cooling device main body 1, and a drive is fixedly connected to the inner left end of the cooling device main body 1 The motor 11, the output shaft of the driving motor 11 is fixedly connected with the stirring shaft 12, the lower end of the stirring shaft 12 is provided with a filter screen plate 17, and the lower end of the filter screen plate 17 is provided with a second conveying slot 20,...

Embodiment 2

[0026] like Figure 1-5 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: preferably, the inner side of the support rod 7 is movably connected with a movable shaft, and the outside of the movable shaft is provided with a transmission plate 5, and the front of the movable shaft penetrates On the front and rear sides of the support rod 7, a servo motor 8 is fixedly installed on the front of the support rod 7, and the output end of the servo motor 8 is fixedly connected to the front of the set movable shaft. The combination of the transmission plate 5, the support rod 7 and the movable shaft of the servo motor 8 is set , it is convenient to transport and cool the stirred and pulverized fertilizer, so that the fertilizer can be uniformly cooled, and the working efficiency of the device can be improved. The back side of the cooling device 13 is fixedly installed with the front side of the connecting pipe 10, the lower end of the first cool...

Embodiment 3

[0028] like Figure 1-5 As shown, on the basis of Example 1, the present invention provides a technical solution: preferably, a cooling method for fertilizer production, which is suitable for a cooling device for fertilizer production described in claims 1-6 , including the following steps: step 1: stirring and pulverizing, transferring the material from the feeding port 2 to the inside of the cooling device main body 1, then using the control element 6 to control the cooling device main body 1, and then driving the stirring shaft 12 to rotate, using The set stirring element 21 stirs the fertilizer; Step 2: The fertilizer is filtered. After the fertilizer enters, the fertilizer with a smaller volume is dropped to the inside of the second conveying tank 20 through the filter screen 17, and then transferred to the first conveying tank. 18, the material after stirring and pulverizing is transported by the first conveying tank 18, and then conveyed to the upper end of the conveyin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com