Intelligent control system for crushing

An intelligent control system and control system technology, which is used in comprehensive factory control, lighting and heating equipment, grain processing, etc., can solve the problem that the broken materials cannot be discharged through the sieve plate, the sieve holes of the sieve plate are easy to be blocked, and the shutdown and blockage are cleared, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

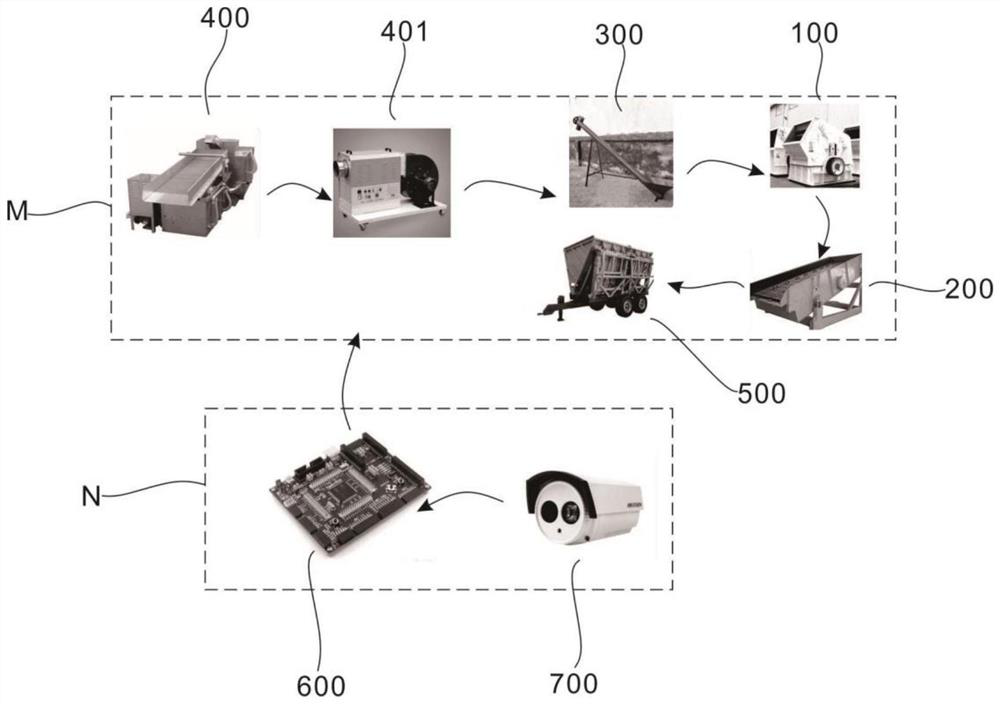

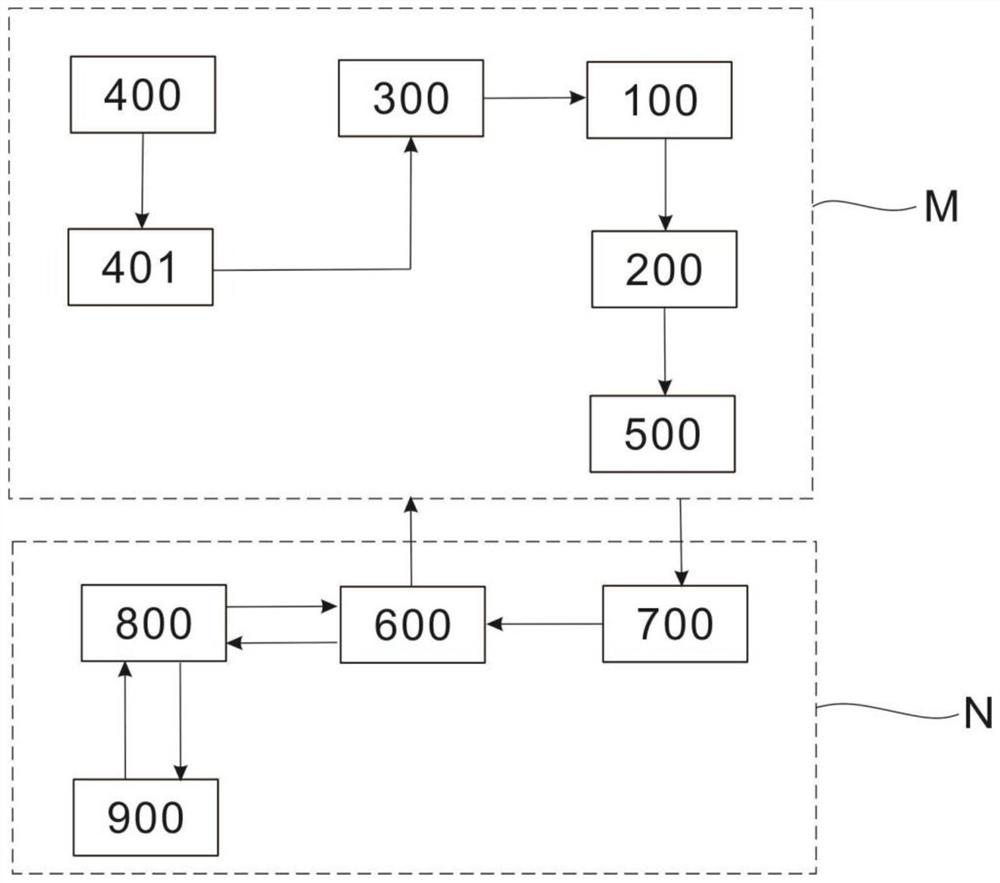

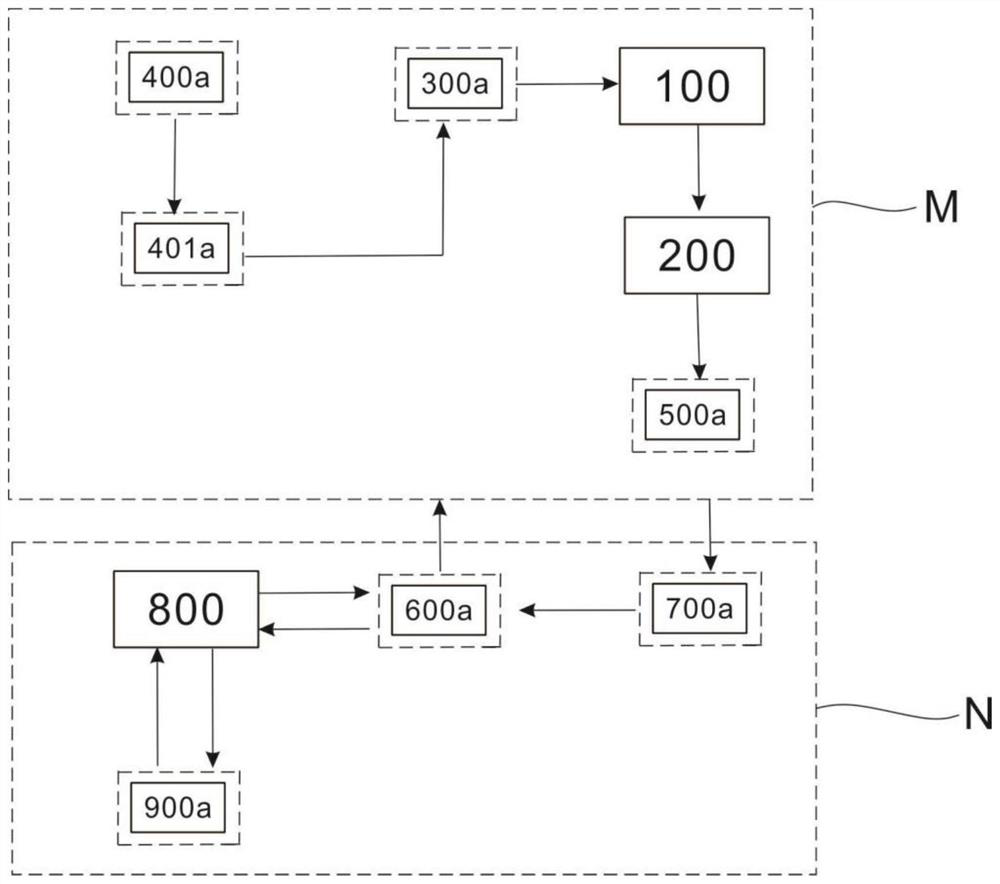

[0032] refer to Figures 1 to 3 , is the first embodiment of the present invention, this embodiment provides an intelligent control system for crushing, which can systematically clean, feed and crush materials, produce materials that meet the requirements of use accuracy and transport them .

[0033] Specifically, the production system M includes a crushing module 100 , a screening module 200 connected to the bottom of the crushing module 100 , a feeding module 300 connected to the crushing module 100 , and a cleaning module connected to the feeding module 300 400, and a transport module 500 connected with the screening module 200;

[0034] The control system N, connected to the production system M, includes a field control module 600 and an acquisition module 700 connected to the field control module 600 .

[0035] Further, the control system N further includes a wireless transceiver module 800 connected to the on-site control module 600 , and a remote terminal 900 connecte...

Embodiment 2

[0043] refer to Figures 4 to 10 , which is the second embodiment of the present invention. This embodiment provides the specific structures of the crushing module 100 and the screening module 200, which can automatically dry the blocked screening tray and adjust the drying intensity adaptively without manual maintenance. . The materials dried by the hot air module 401 will still have a certain amount of moisture, which will block the screening tray during screening.

[0044] Specifically, the crushing module 100 includes a driving component 101, a crushing component 102 connected with the driving component 101, and a fixed housing 103 connected with the crushing component 102;

[0045] The screening module 200 is arranged below the crushing module 100, and includes a screening and condensing assembly 201 connected to the fixed shell 103, a double-layer screening and drying assembly 202 disposed in the screening and condensing assembly 201, The distance-adjusting and connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com