Preparation process of jasmine tea craft beer

A kind of jasmine tea and the technology of preparation process, which is applied in the field of brewing, can solve the problems of increased process, complex process, high bitterness and astringency, and achieve the effect of reducing bitterness, high acceptability, rich jasmine fragrance and tea fragrance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

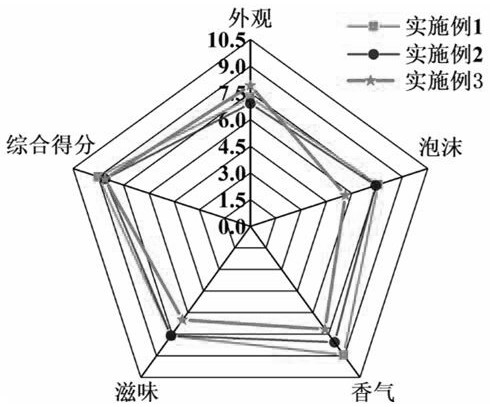

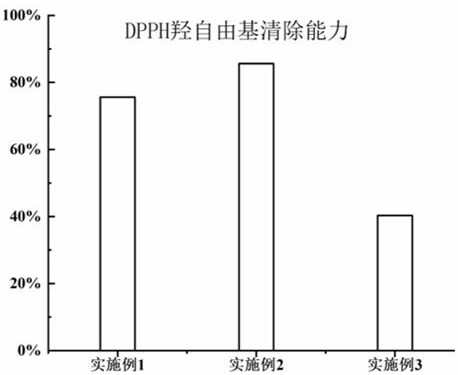

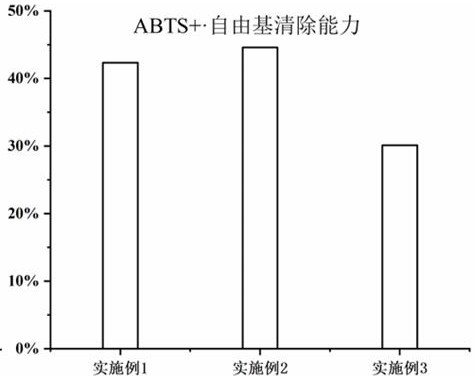

Embodiment 1

[0027] (1) Preparation of wheat mash: 50kg of barley sprouts and 25kg of wheat malts are pulverized to a certain extent and mixed with 300L of water to prepare wheat mash;

[0028] (2) Saccharification and filtration of wort: saccharification is carried out by staged heating. The heating program is: 40-45 °C, hold for 10 minutes, then heat up to 45-50 °C, hold for 20 minutes, then heat up to 60-65 °C, hold for 30 minutes, and then Raise the temperature to 70-75°C, hold for 30 minutes, then raise the temperature to 75-78°C, hold for 5 minutes, and finally raise the temperature to 78-80°C and hold for 5 minutes. After mashing, pump the mash into the filter tank and let it stand for 15 minutes, open the filter valve and put the wort into the rotary sedimentation tank, spin for 15 minutes, and use the transfer pump to pump the wort into the boiling pot;

[0029] (3) Preparation of jasmine tea powder: jasmine tea is extracted with water at 45-65°C for 20-40 min, and the extract is ...

Embodiment 2

[0033] Compared with Example 1, the difference in the brewing process of the jasmine tea beer described in this example only exists in that: in the brewing process, jasmine tea is added instead of jasmine tea powder, and the amount of jasmine tea added accounts for 0.4% of the brewing water. .

Embodiment 3

[0035] (1) Preparation of malt powder: 50kg of barley malt and 25kg of wheat malt are pulverized to a certain extent, and the malt mash is prepared by mixing with 300L of water;

[0036] (2) Saccharification of wort: saccharification is carried out by staged heating. The heating program is: 40-45 °C, hold for 10 min, then heat up to 45-50 °C, hold for 20 min, then heat up to 60-65 °C, hold for 30 min, The temperature was increased to 70-75 °C and held for 30 min, then increased to 75-78 °C and held for 5 min, and finally increased to 78-80 °C and held for 5 min. And through one filtration to get wort, and use the transfer pump to pump the wort into the boiling pot;

[0037] (3) Boil the wort: Boil in a boiling pot for 110 minutes, and add hops during the process. The time for adding hops is 20 minutes after boiling, and the amount added is 0.083% of the amount of brewing water. After the boiled wort is spin-sinked for 15 minutes, the activated yeast (dry yeast with 0.05% brew...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com