Permanent magnet coupler copper disc and mounting disc potting heat conduction structure

A technology for mounting disks and couplings, which is applied in permanent magnet clutches/brakes, electromechanical devices, transportation and packaging, etc., and can solve problems such as inability to effectively ensure effective heat conduction between copper disks and mounting disks, and dust entry.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

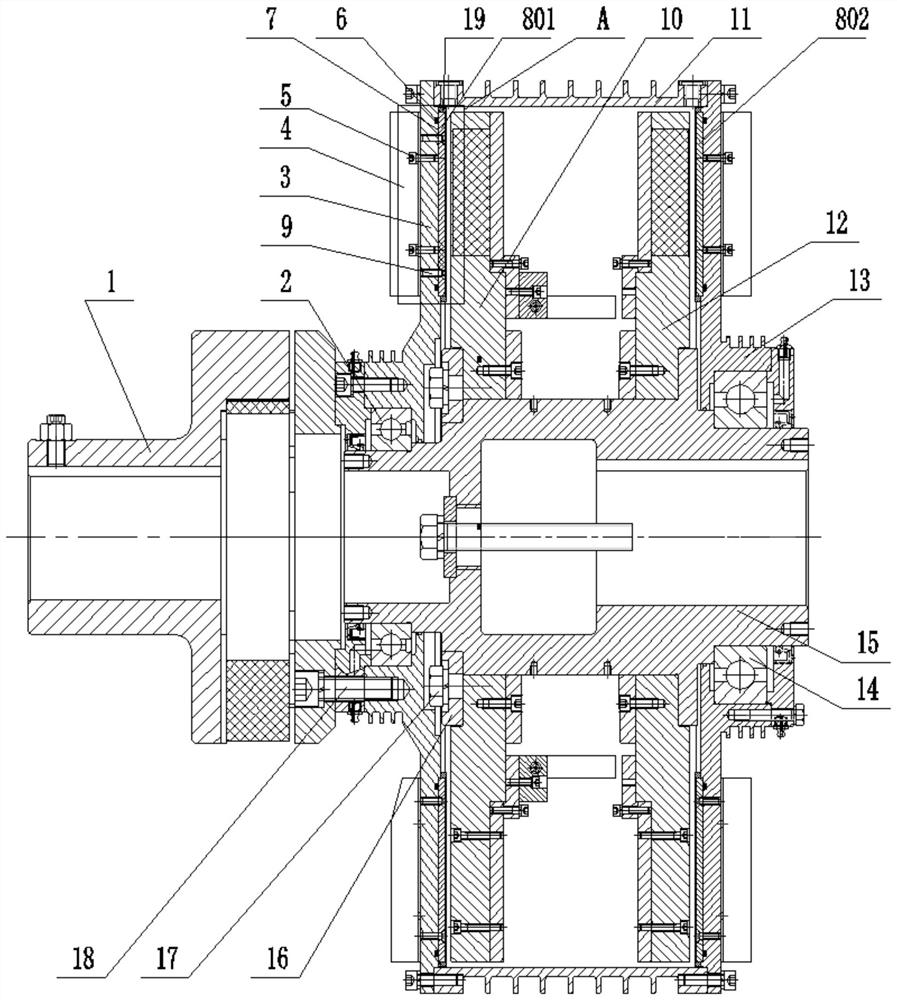

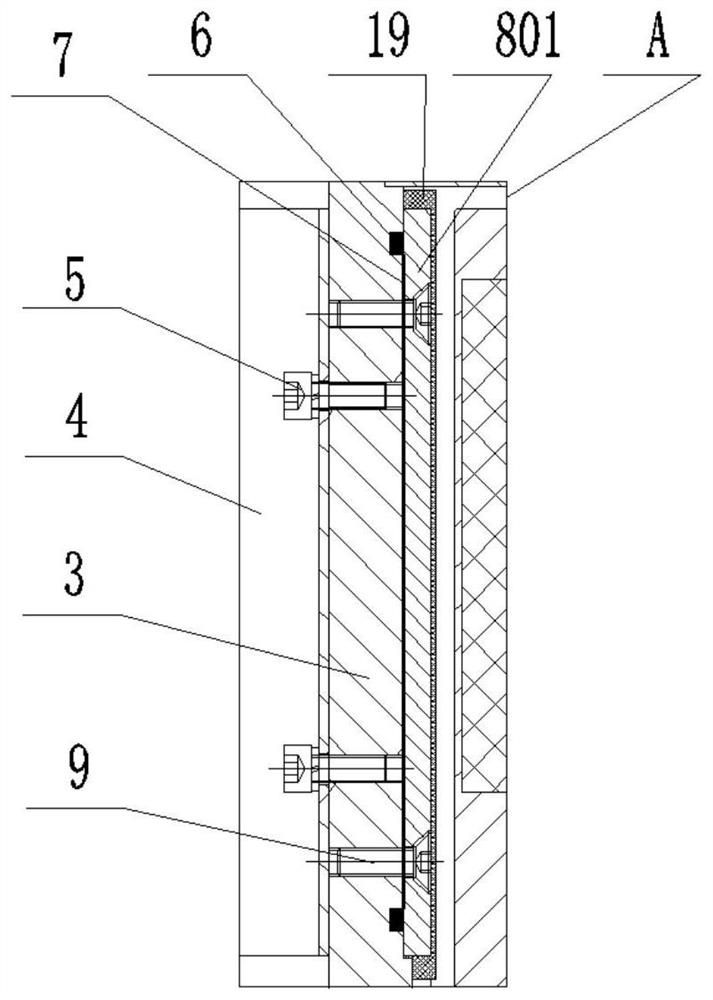

[0021] like figure 1 and figure 2 As shown, a heat conduction optimization technology of permanent magnet coupling copper plate and mounting plate potting includes input mounting plate 3, input copper plate 801, output mounting plate 13 and output copper plate 802; the input mounting plate 3 and the output mounting plate The disks 13 are respectively mounted on both sides of the output square shaft assembly 15 through the input deep groove ball bearing 2 and the output deep groove ball bearing 14, and the input mounting disk 3 and the output mounting disk 13 are respectively mounted on the input deep groove ball bearing 2 and the output deep groove ball bearing 2. On the outer ring of the groove ball bearing 14, the input deep groove ball bearing 2 and the inner ring of the output deep groove ball bearing 14 are respectively installed on both sides of the output square shaft assembly 15, and the inner sides of the input installation plate 3 and the output installation plate 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com