Lamp capable of purifying water

A technology for purifying water quality and lamps, applied in chemical instruments and methods, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc., can solve problems affecting water tanks, poor investment economy, poor use economy, etc., to achieve Reduce the working temperature, prolong the working life and reduce the effect of faulty nodes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

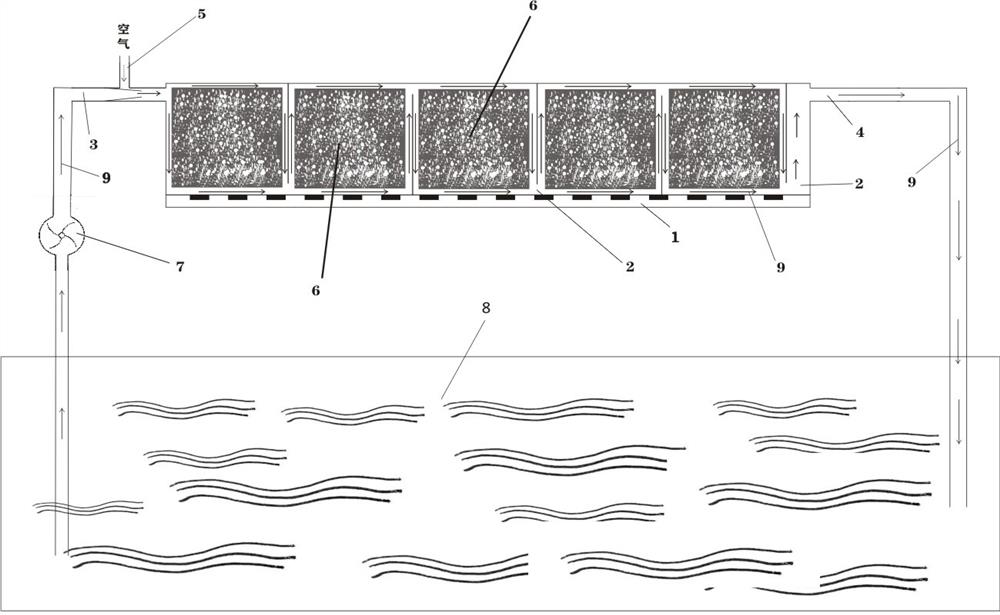

[0037] Block silo structure ( figure 2): The structure of a lamp for purifying water quality according to the present invention includes a lamp compartment 1, a water cooling compartment 2, a water cooling compartment water inlet 3, a water cooling compartment water outlet 4, and a water cooling compartment 2. The water inlet 3 is provided with a differential pressure oxygenation port 5. The cooling water of the external water tank enters the water inlet 3 of the water cooling chamber 2 through the water pump; the water outlet 4 of the water cooling chamber 2 is connected to the external water tank, so that the cooling water in the water cooling chamber flows back into the external water tank, forming an external water tank---water pump-- - Water inlet 3 of water cooling chamber --- Water cooling chamber 2 --- Water outlet 4 of water cooling chamber --- External circulating water circuit of external water tank ( Figure 1 ). The water flow entering the water inlet 3 of the w...

Embodiment 2

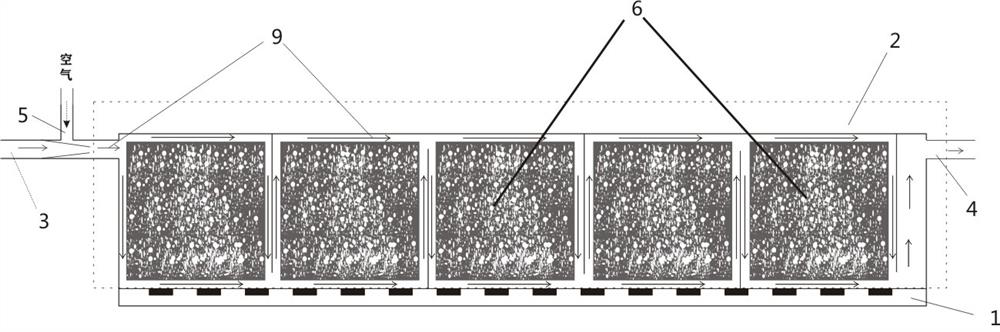

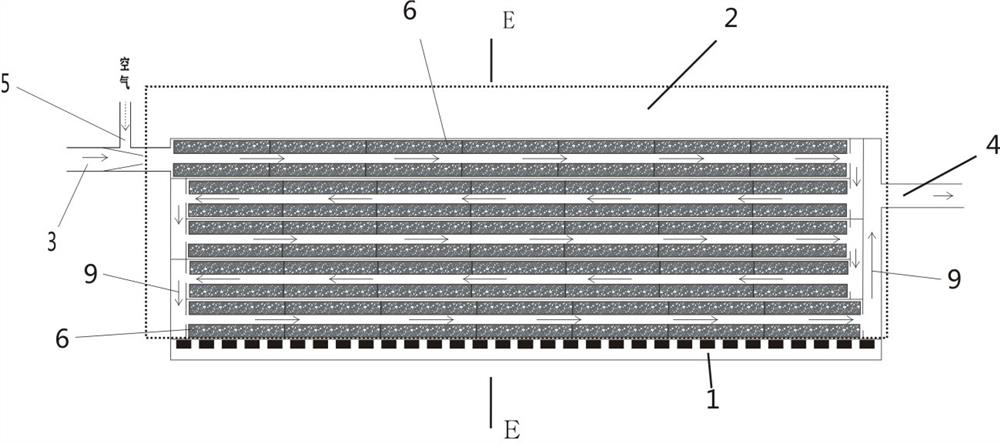

[0039] Flat warehouse structure ( image 3 , Figure 4 ): The structure of a lamp for purifying water quality according to the present invention includes a lamp compartment 1, a water cooling compartment 2, a water cooling compartment water inlet 3, a water cooling compartment water outlet 4, and a water cooling compartment 2. The water inlet 3 is provided with a differential pressure oxygenation port 5. The cooling water of the external water tank enters the water inlet 3 of the water cooling chamber 2 through the water pump; the water outlet 4 of the water cooling chamber 2 is connected to the external water tank, so that the cooling water in the water cooling chamber flows back into the external water tank, forming an external water tank---water pump-- - Water inlet 3 of water cooling chamber --- Water cooling chamber 2 --- Water outlet 4 of water cooling chamber --- External circulating water circuit of external water tank ( Figure 1 ). The water flow entering the water...

Embodiment 3

[0041] Channel bin structure ( Figure 5 , Image 6 , Figure 7 ): The structure of a lamp for purifying water quality according to the present invention includes a lamp compartment 1, a water cooling compartment 2, a water cooling compartment water inlet 3, a water cooling compartment water outlet 4, and a water cooling compartment 2. The water inlet 3 is provided with a differential pressure oxygenation port 5. The cooling water of the external water tank enters the water inlet 3 of the water cooling chamber 2 through the water pump; the water outlet 4 of the water cooling chamber 2 is connected to the external water tank, so that the cooling water in the water cooling chamber flows back into the external water tank, forming an external water tank---water pump-- - Water inlet 3 of water cooling chamber --- Water cooling chamber 2 --- Water outlet 4 of water cooling chamber --- External circulating water circuit of external water tank ( Figure 1 ). The water flow entering...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com