Casting method of copper-steel bimetallic composite material for plunger pump cylinder body

A composite material and bimetal technology, which is applied in the field of copper-steel bimetal composite material melting and casting, can solve the problems of difficulty in producing large cylinder blocks, limited size of cylinder blocks, and large use of copper alloys, and achieves cooling. The conditions are easy to control, the production cost is low, and the equipment occupies a small area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A method for melting and casting a copper-steel bimetallic composite material for a cylinder block of a plunger pump, comprising the following steps:

[0032] (1) Raw material treatment: clean the steel substrate and the copper alloy surface to remove the contaminants on the metal surface;

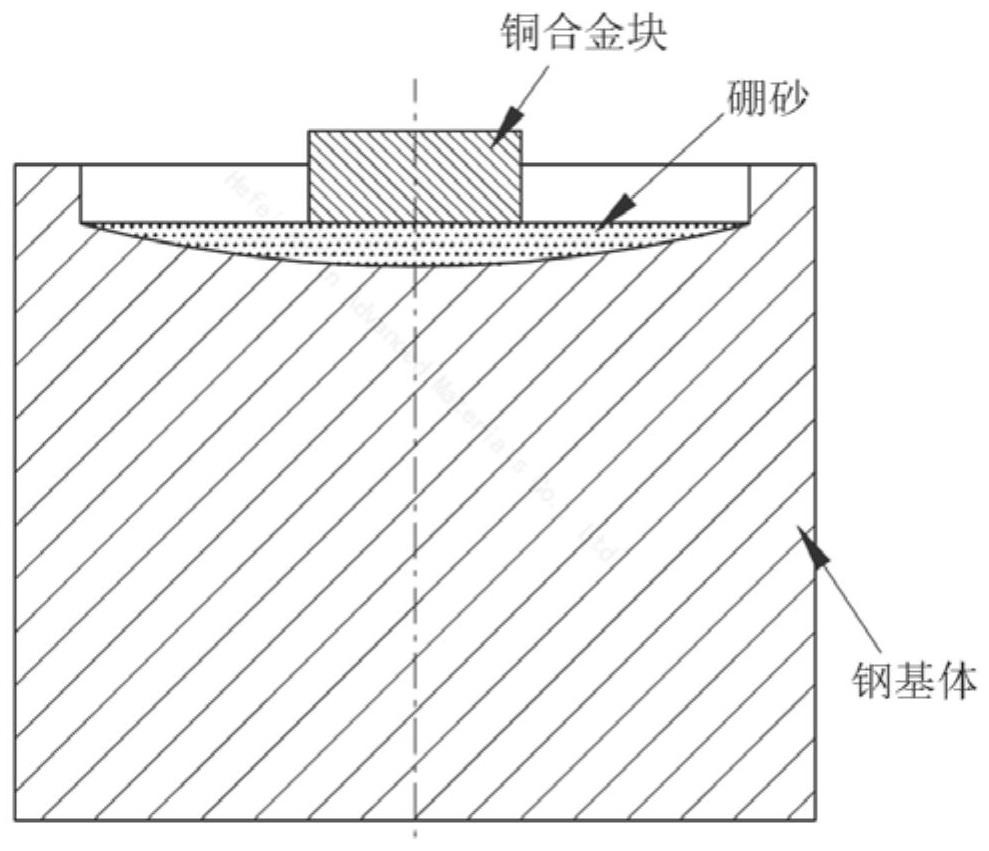

[0033] (2) Add sand: add an appropriate amount of anhydrous borax in a loose state to the molten copper pool of the steel matrix, and then place the copper alloy on the borax;

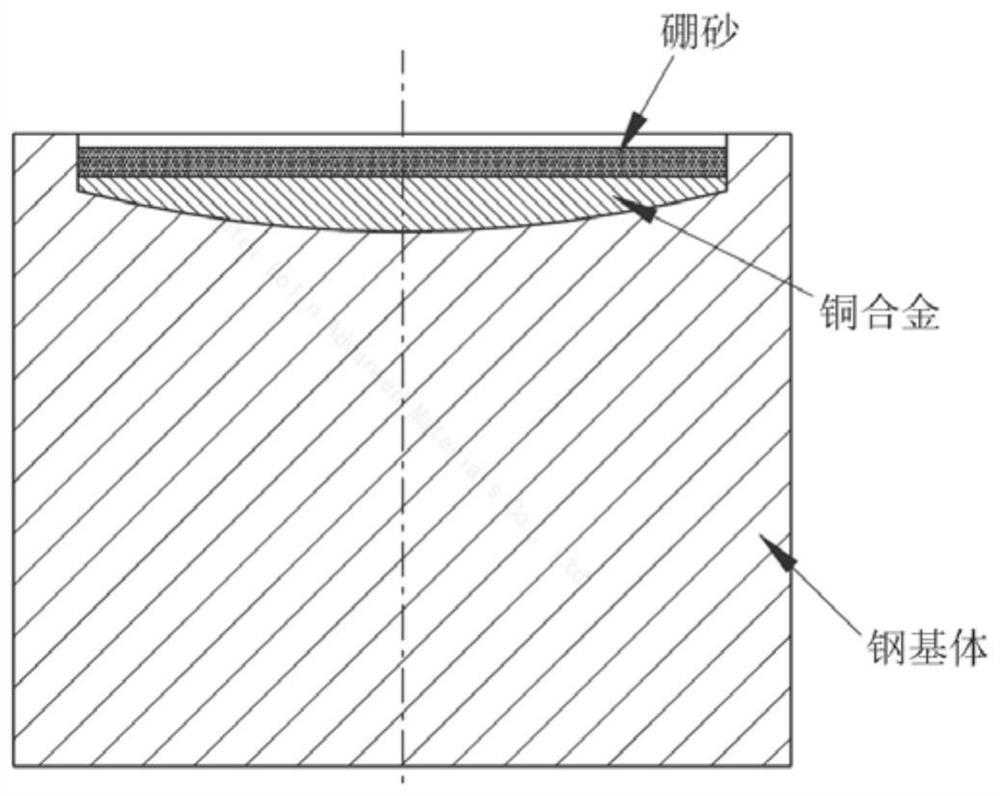

[0034] (3) High temperature casting: Put the steel matrix and the copper alloy into the casting furnace, and use nitrogen with a purity of ≥99.99% as the protective atmosphere. When the temperature rises to 1050℃, the holding time is 60min;

[0035] (4) Cooling: The steel matrix and the melted copper alloy are taken out from the melting and casting furnace, and air-cooled, and cooled to room temperature when cooled to below 500°C.

Embodiment 2

[0037] A method for melting and casting a copper-steel bimetallic composite material for a cylinder block of a plunger pump, comprising the following steps:

[0038] (1) Raw material treatment: clean the steel substrate and the copper alloy surface to remove the contaminants on the metal surface;

[0039] (2) Add sand: add an appropriate amount of anhydrous borax in a loose state to the molten copper pool of the steel matrix, and then place the copper alloy on the borax;

[0040] (3) High temperature casting: Put the steel matrix and the copper alloy into the casting furnace, and use nitrogen with a purity of ≥99.99% as the protective atmosphere. When the temperature rises to 1100℃, the holding time is 50min;

[0041] (4) Cooling: The steel matrix and the melted copper alloy are taken out from the melting and casting furnace, and air-cooled, and cooled to room temperature when cooled to below 500°C.

Embodiment 3

[0043] A method for melting and casting a copper-steel bimetallic composite material for a cylinder block of a plunger pump, comprising the following steps:

[0044] (1) Raw material treatment: clean the steel substrate and the copper alloy surface to remove the contaminants on the metal surface;

[0045] (2) Add sand: add an appropriate amount of anhydrous borax in a loose state to the molten copper pool of the steel matrix, and then place the copper alloy on the borax;

[0046] (3) High temperature casting: Put the steel matrix and the copper alloy into the casting furnace, and use nitrogen with a purity of ≥99.99% as the protective atmosphere. When the temperature rises to 1150℃, the holding time is 40min;

[0047] (4) Cooling: The steel matrix and the melted copper alloy are taken out from the melting and casting furnace, and air-cooled, and cooled to room temperature when cooled to below 500°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com