Functional polyester production system, preparation method and functional polyester fiber

A production system, polyester oligomer technology, applied in the field of functional polyester fiber and functional polyester production system, can solve the problems of functional powder re-agglomeration, etc., to improve the dispersion state, improve performance, and improve spinning performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

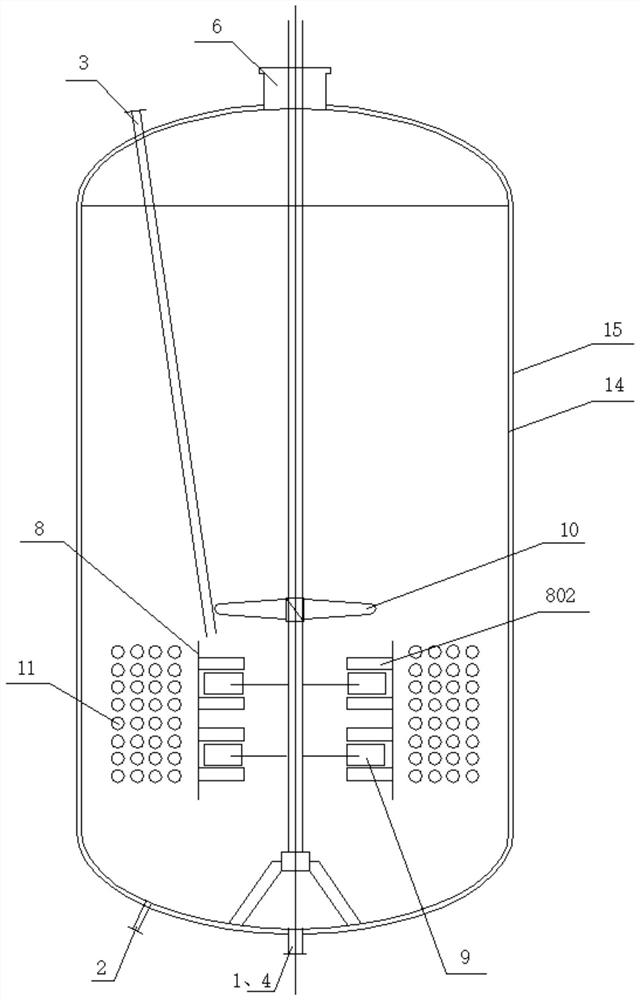

[0074] As an embodiment of the present invention, this embodiment provides a high-shear reaction kettle with a reaction chamber inside, and a radial flow stirring paddle 9 for driving the reactants to flow in the radial direction is arranged in the reaction chamber. In this embodiment For example, as figure 1 As shown, the shear jet mechanism is a guide tube 8 that is sleeved on the outside of the radial flow stirring paddle 9 and is coaxially arranged with the radial flow stirring paddle 9. The guide tube 8 has a cylindrical structure. The inner walls are connected to achieve fixation. The two sides of the guide cylinder 8 in the axial direction have openings. The cylindrical peripheral wall is provided with a guide area opposite to the position of the radial flow stirring paddle 9. In the guide hole 801, during the rotation of the radial flow stirring paddle 9, the reactant is driven to move in the radial direction, and the reactant is blocked by the guide tube 8, and part o...

Embodiment 2

[0083] As another embodiment of the present invention, this embodiment is further improved on the basis of Embodiment 1, and the details are as follows.

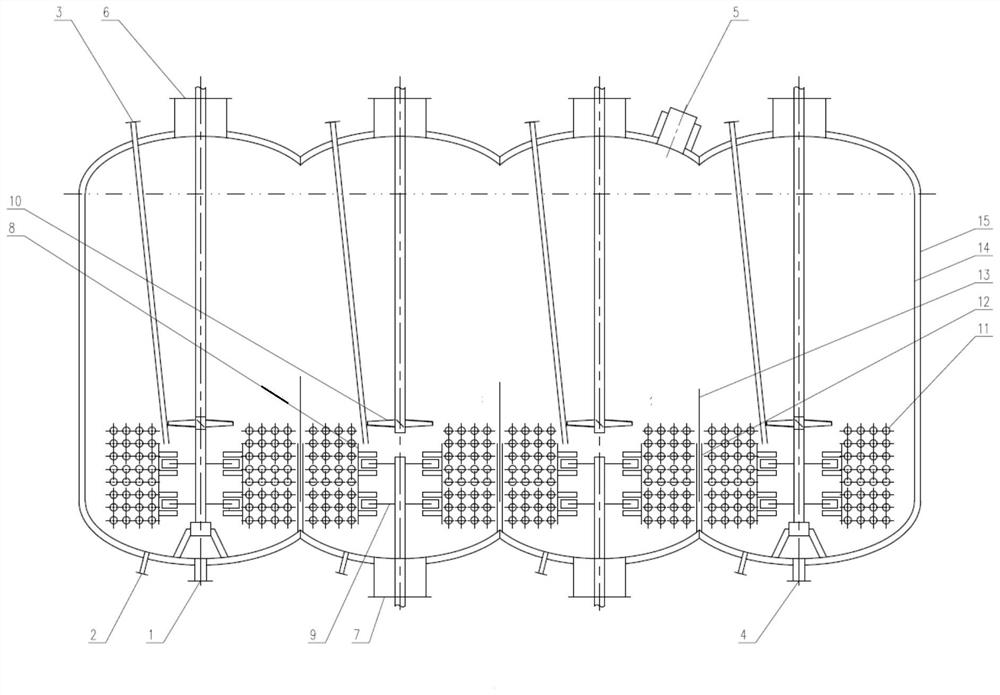

[0084] like Figure 4 and Figure 5 As shown, in this embodiment, the high shear reactor also includes,

[0085] The baffle 802 is fixed on the guide tube 8 and extends inward from the inner wall of the guide tube 8 .

[0086] The baffle 802 is located on one side of the paddle along the axial direction of the guide tube 8 , and is fixedly connected to the inner wall of the guide tube 8 .

[0087] Specifically, the plane where the baffle plate 802 is located is parallel to the axis of the guide tube 8 , and the length along the radial direction of the guide tube 8 is greater than the gap between the guide tube 8 and the end of the blade , the radial flow stirring paddle 9 drives the reactant to move in the circumferential direction of the diversion cylinder 8 during the rotation process. When passing through the baffle 80...

Embodiment 3

[0093] As another embodiment of the present invention, this embodiment makes further improvements on the basis of the second embodiment, and the details are as follows.

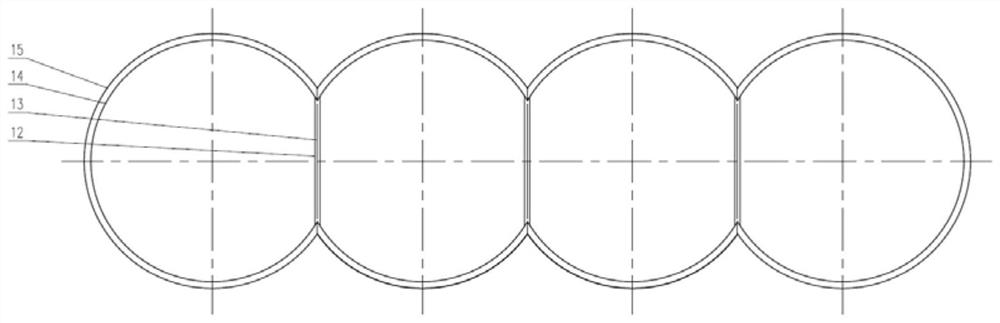

[0094] In this embodiment, the radial flow stirring paddle 9 and the guide cylinder 8 are located at the lower part of the reactor, and an axial flow stirring paddle for guiding the reactants to flow along the axial direction to the radial flow stirring paddle 9 is also provided in the reactor. 10, the axial flow stirring paddle 10 can be arranged above or below the radial flow stirring paddle 9; the above-mentioned scheme is formed in the reactor by the radial flow stirring paddle 9, the guide cylinder 8 and the axial flow stirring paddle 10 for the circulation of the reactants. The passage of the duct, so that the reactants located outside the diversion cylinder 8 can be continuously supplemented into the interior of the diversion cylinder 8, thereby realizing the full dispersion of the functional powder in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Intrinsic viscosity | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com