MOG fluorescent ink as well as preparation method and information encryption and anti-counterfeiting application thereof

A technology of fluorescent inks and ligands, applied in inks, applications, household appliances, etc., can solve the problems of low absorption rate of lanthanide ions, and achieve the effects of short reaction time, simple operation, and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) Prepare the fluorescent ink of MOG1:

[0030] Step (1-1): take 0.8mmol 2,6-pyridinedicarboxylic acid and 0.2mmol 5-aminoisophthalic acid (mol ratio is 4:1), measure 2mL ethanol and add it to a clean small glass bottle together, Sonicate for one minute, then add 280 μL of triethylamine reagent with a pipette, and continue to sonicate until it is completely dissolved into a clear and transparent solution.

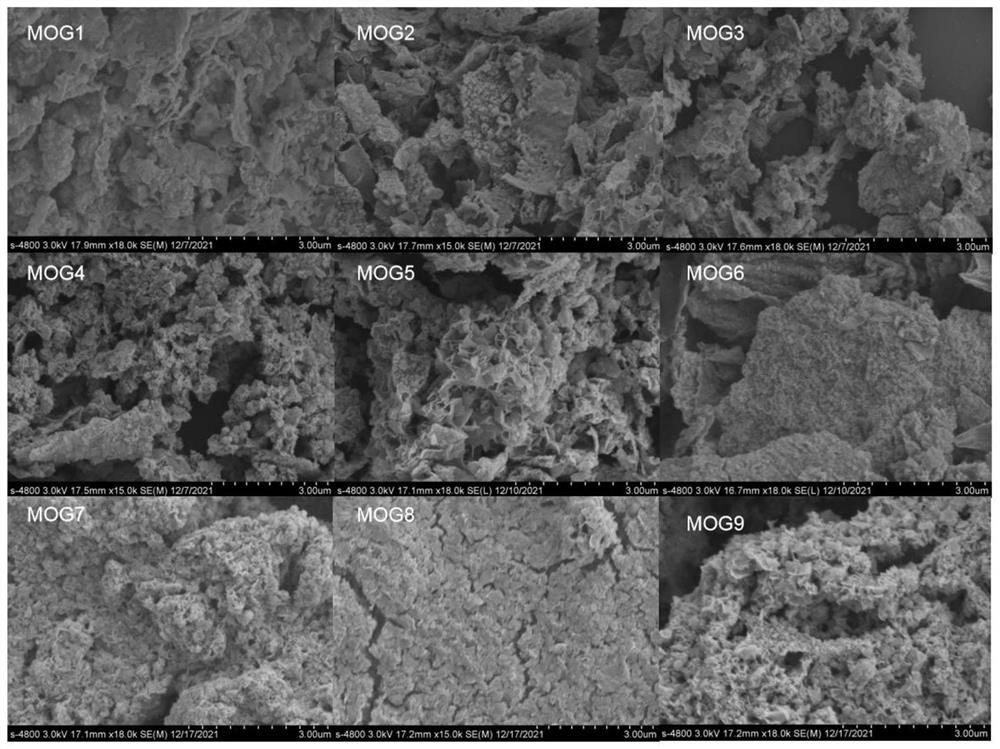

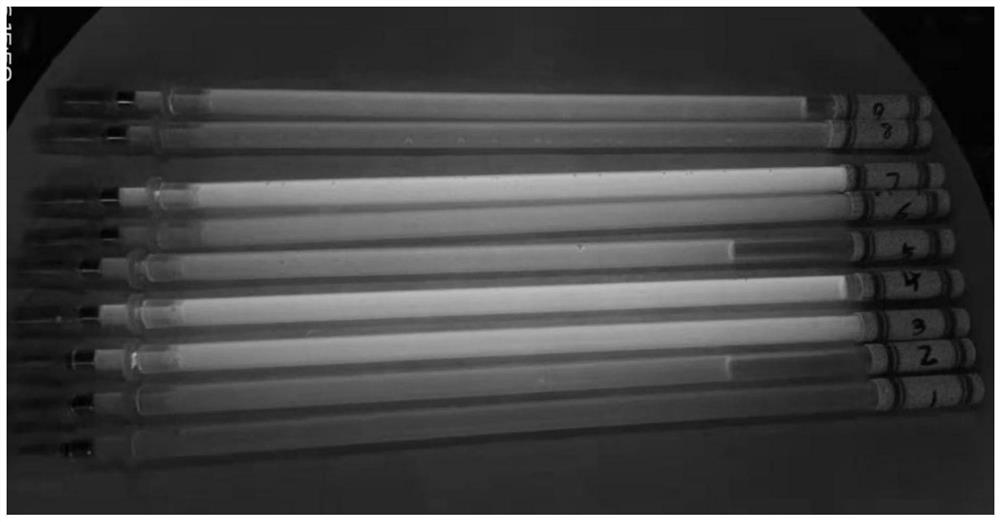

[0031] Step (1-2): 1 mmol Eu (NO 3 ).6H 2 Add O into 2 mL of ethanol and sonicate until it is completely dissolved, then transfer the mixed solution to the above-mentioned small glass bottle at one time, and quickly stir with a small glass rod to form a gel. After standing for a period of time, turn the small glass bottle upside down, the formed gel does not fall off, and MOG1 is successfully prepared, such as figure 1 shown. The MOG1 prepared above was washed three times with deionized water and ethanol, dehydrated and dried for 12 hours, and then taken out to...

Embodiment 2

[0042] (1) Prepare the fluorescent ink of MOG1:

[0043] Step (1-1): take 0.8mmol of 2,6-pyridinedicarboxylic acid and 0.2mmol of 2-aminoterephthalic acid (mol ratio is 4:1), measure 2mL of ethanol and add it into a clean small glass bottle together, Sonicate for one minute, then add 280 μL of triethylamine reagent with a pipette, and continue to sonicate until it is completely dissolved into a clear and transparent solution.

[0044] Step (1-2): 1 mmol EuCl 3 .6H 2 Add O into 2 mL of ethanol and sonicate until completely dissolved, then transfer the mixed solution to the above-mentioned small glass bottle at one time, and quickly stir with a small glass rod to form a gel. After standing for a period of time, the small glass bottle was inverted, the formed gel did not fall off, and MOG1 was successfully prepared. The MOG1 prepared above was washed three times with deionized water and ethanol each, dehydrated and dried for 12 hours, and then taken out to obtain a dry gel. W...

Embodiment 3

[0054] (1) Prepare the fluorescent ink of MOG1:

[0055] Step (1-1): take 0.8mmol 2,5-pyridinedicarboxylic acid and 0.2mmol 2-aminophthalic acid (molar ratio is 4:1), measure 2mL ethanol and add it to a clean small glass bottle together, Sonicate for one minute, then add 280 μL of triethylamine reagent with a pipette, and continue to sonicate until it is completely dissolved into a clear and transparent solution.

[0056] Step (1-2): 1 mmol Eu (NO 3 ).6H 2 Add O into 2 mL of ethanol and sonicate until completely dissolved, then transfer the mixed solution to the above-mentioned small glass bottle at one time, and quickly stir with a small glass rod to form a gel. After standing for a period of time, the small glass bottle was inverted, the formed gel did not fall off, and MOG1 was successfully prepared. The MOG1 prepared above was washed three times with deionized water and ethanol each, dehydrated and dried for 12 hours, and then taken out to obtain a dry gel. Weigh 10 mg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com