Batching method of organic substrate in combined anaerobic fermentation and combined anaerobic fermentation method

An organic substrate, anaerobic fermentation technology, applied in the direction of biochemical equipment and methods, fermentation, microbial measurement/inspection, etc., can solve the problems of time-consuming and laborious results, the inability to guarantee the synergistic effect of multiple materials, and lack of universality. Achieve high synergy index, improve synergy effect, and high gas production rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Binary distribution ratio:

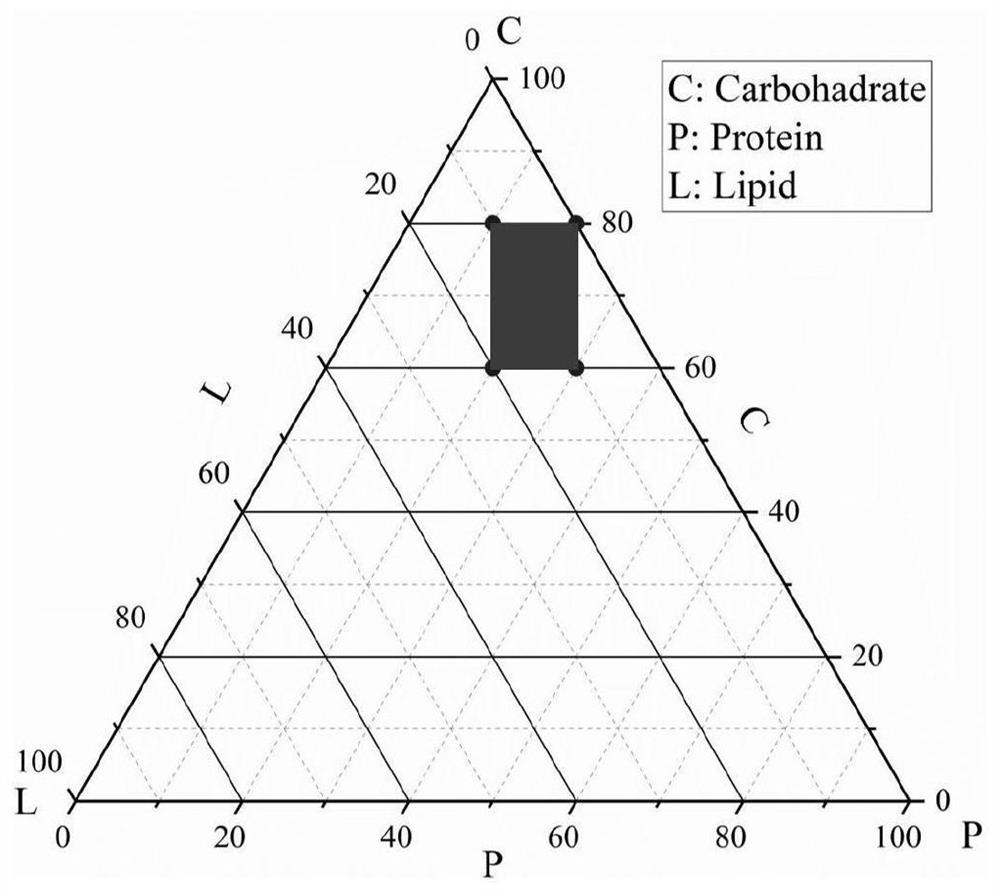

[0047] Food waste, corn stalk and chicken manure were selected as organic substrate raw materials, and the mass percentage contents of protein, lipid, lignin and volatile solid were detected respectively, and the obtained volatile solid content, protein content, lipid content and volatile solid content were used. The lignin content calculates the carbohydrate content in the organic substrate, said carbohydrate content = volatile solids content - protein content - lipid content - lignin content;

[0048] It is obtained that the mass percentages of carbohydrates, proteins and lipids in the kitchen waste relative to the volatile solids are 75.7%, 18.8% and 0.5%, respectively. The carbohydrates, proteins and lipids of the corn stover are relative to the volatile solids. The mass percentages in the chicken manure were 85.3%, 5.5% and 0, respectively, and the mass percentages of carbohydrates, proteins, and lipids in chicken manure relative to the...

Embodiment 2

[0058] Triple allocation ratio:

[0059] Select corn stalks, chicken manure and kitchen waste as organic substrate raw materials, and detect the mass percentage content of protein, lipid, lignin and volatile solid in the organic substrate respectively, and use the obtained volatile solid content, protein content, lipid content Content and Lignin Content Calculate the carbohydrate content in the organic substrate, the carbohydrate content = volatile solids content - protein content - lipid content - lignin content, resulting in protein content, lipid content and carbohydrate content, respectively content;

[0060] The mass percentages of carbohydrates, proteins, and oils in corn stover relative to volatile solids were 61.61%, 6.48%, and 1.50%, respectively, and the mass percentages of carbohydrates, proteins, and oils in chicken manure relative to volatile solids were The contents are 41.58%, 38.53% and 6.01% respectively, and the mass percentages of carbohydrates, proteins an...

Embodiment 3

[0074] The organic substrate raw materials are corn stover, chicken manure and slaughter waste, and the method for determining the carbohydrate content is the same as that in Example 2. It is obtained that the carbohydrate, protein, and oil content of the corn stover relative to the mass percentage in the volatile solids are respectively: 61.61%, 6.48% and 1.50%, the mass percentages of carbohydrates, proteins and oils in chicken manure relative to volatile solids were 41.58%, 38.53% and 6.01% respectively, and the carbohydrates, proteins and oils in slaughter waste were The mass percentages relative to the volatile solids are 0.10%, 55.73% and 43.91%, respectively;

[0075] The raw material combination contains carbohydrates, proteins and lipids at the same time. According to the mass ratio of corn stover, chicken manure and slaughter waste, the ingredients are 185:936:100 (corn stover is 2.76g, chicken manure is 13.94g, The slaughter waste was 1.49 g), and the mass ratio of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com