Turnover type tea leaf drying equipment for tea art

A drying equipment and flip-type technology, applied in non-progressive dryers, drying chambers/containers, drying solid materials, etc., can solve the problems of reducing the drying effect of tea leaves, uneven drying of tea leaves, easy aggregation of tea leaves, etc., to achieve Reduced strength, improved convenience, avoid drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

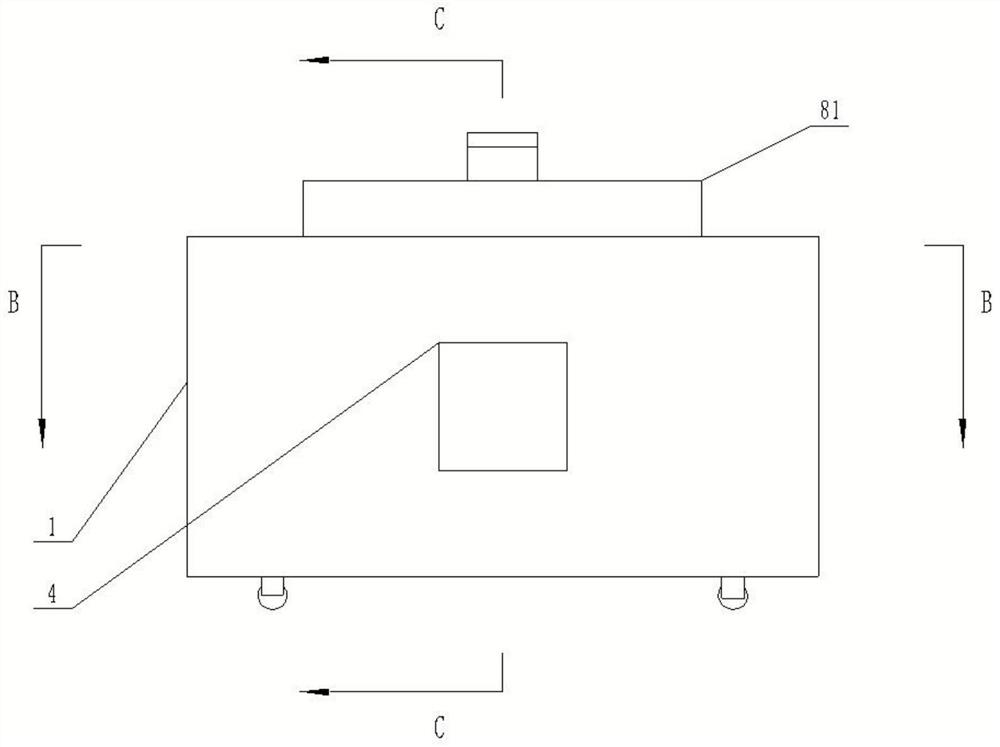

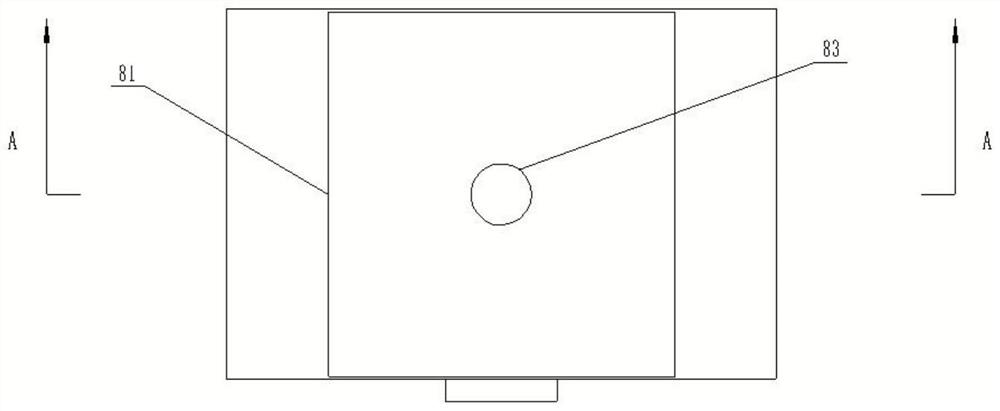

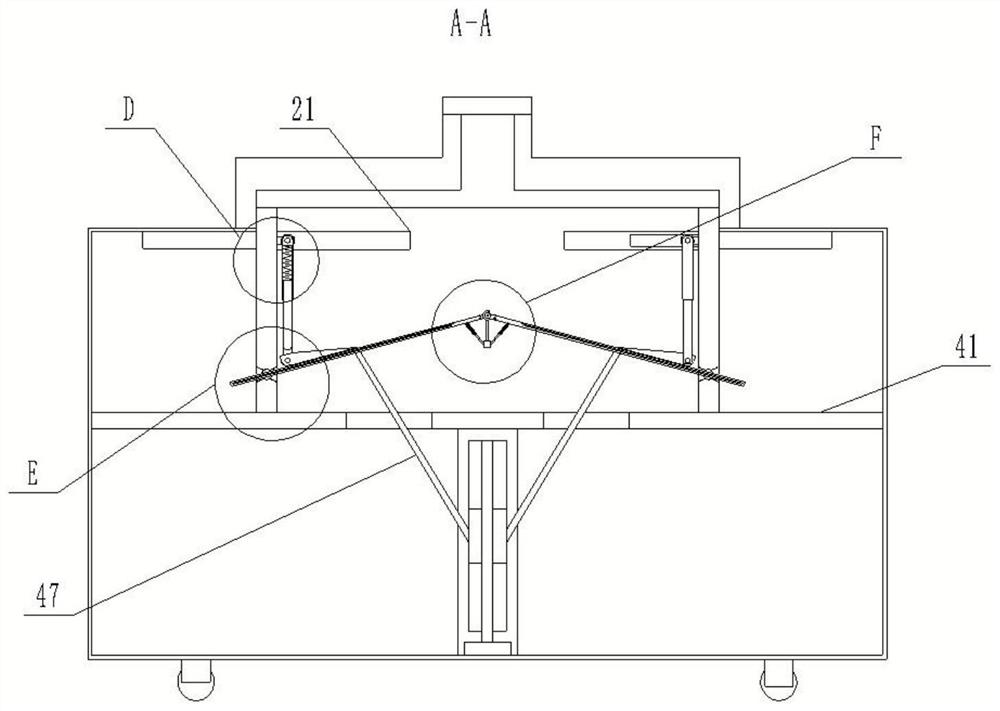

[0023] like figure 1 As shown in the figure, an inversion type tea drying equipment for tea art includes: a casing 1, a rectangular drying barrel 2, an inversion drying assembly, and a rectangular drying barrel 2, which are arranged on the upper side of the interior of the casing 1, and the rectangular drying barrel 2 is connected with The shell 1 is connected; the inversion drying assembly is arranged inside the rectangular drying barrel 2 to realize the inversion drying of the tea leaves; the inversion drying assembly includes: two first rotating shafts 3 symmetrically arranged inside the rectangular drying barrel 2 respectively The two sides of the first rotating shaft 3 are rotatably connected with the rectangular drying barrel 2; a plurality of L-shaped hooks are evenly arranged on the two first rotating shafts 3 and are staggered with each other, and one end of the L-shaped hook is connected to the first The rotating shaft 3 is fixedly connected to form an overturning ra...

Embodiment 2

[0026] In order to further facilitate the inversion of the tea leaves, the tea leaves in the rectangular drying barrel can be picked up and turned by the cylinder of the driving mechanism and the first step motor, and the shaking of the turning rake can be realized by the forward and reverse rotation of the first step motor. Dispersing the aggregated tea leaves not only avoids manual drying and reduces the intensity of manual labor, but also can be dried in time after the tea leaves are kneaded, so as to avoid moldy caused by high water content of the tea leaves.

[0027] like Figure 4 As shown, preferably, the drive mechanism includes two chutes 21 opened on the inner walls of both sides of the rectangular drying barrel 2 close to both ends of the first rotating shaft 3, and a cylinder 22 is fixed on the outer side of the rectangular drying barrel 2. The output shaft extends into the chute 21 and is fixed with a first step motor 23, the first step motor 23 is slidably connec...

Embodiment 3

[0029]In order to further improve the flexibility of drying, the adjustable angle bottom plate of the drying barrel formed by the connecting plate, the first connecting column, the second connecting column and the electric heating plate of the drying mechanism enables the drying of the tea leaves to be adjusted according to the state of the tea leaves when the tea leaves are dried. The inclination angle of the bottom plate makes it easy to agglomerate at the initial stage of drying through the conical drying bottom plate. Combined with the overturning rake, the tea leaves are automatically dispersed to both sides to avoid the aggregation of the tea leaves.

[0030] Preferably, the drying mechanism includes two through grooves 31 symmetrically opened at the bottom of the rectangular drying barrel 2 near the two sides of the L-shaped hook, and two second rotating shafts 32 are symmetrically embedded in the through grooves 31 respectively and are rotatably connected with them. Two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com