Conductive composite material and preparation method and application thereof

A technology of conductive composite materials and conductive agents, applied in the direction of conductive materials dispersed in non-conductive inorganic materials, cable/conductor manufacturing, circuits, etc., can solve the problems of high production and storage costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

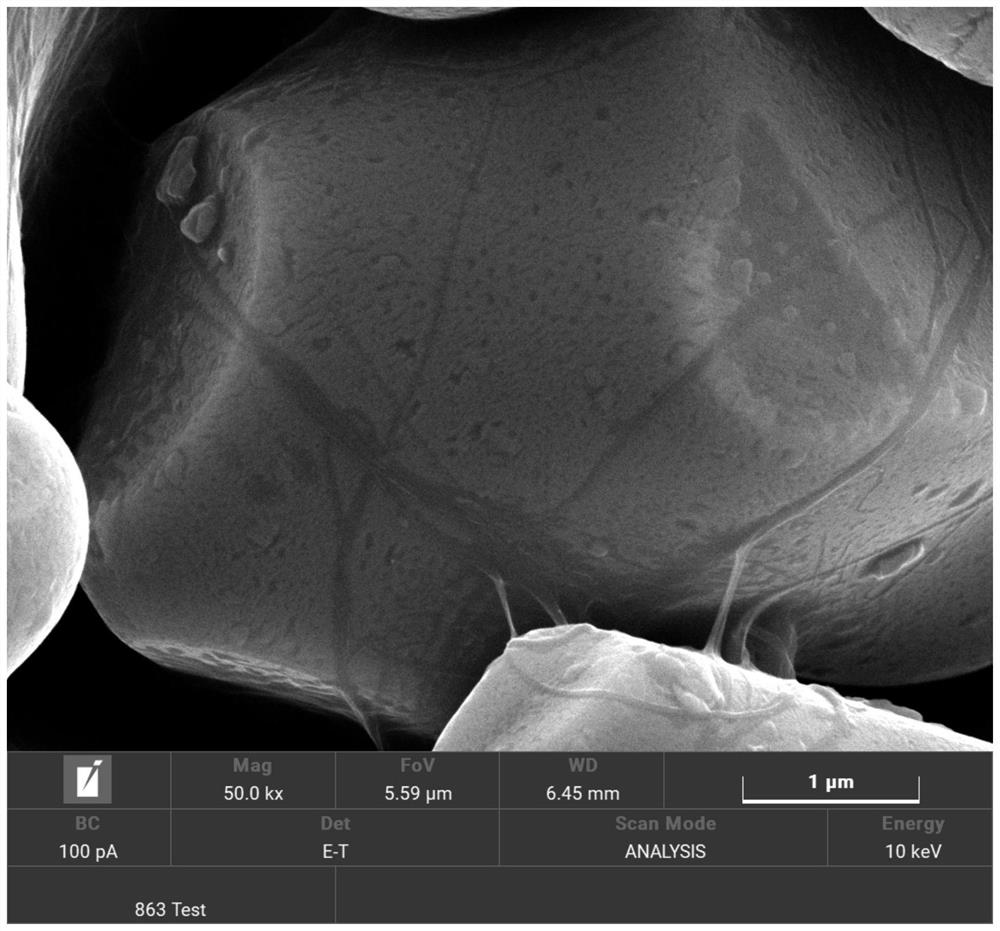

[0066] This embodiment discloses a conductive agent for lithium batteries. The preparation process includes: weighing 100 g of single-walled carbon nanotubes and 1900 g of polyvinylidene fluoride (PVDF), mixing them in a kneader for 30 minutes, and taking out the mixed materials to obtain premix. The setting parameters of the twin-screw extruder are 30 °C in the first zone and 190 °C in the second to sixth zones. After the temperature of the machine rises to the set temperature, the premix is put into the feeding barrel of the twin-screw extruder, and the material is fed and extruded. After granulation, the granulated granules are dried and crushed to below 50 mesh to obtain a lithium battery conductive agent. Among them, the molecular weight of polyvinylidene fluoride is 1.2 million, the length of single-walled carbon nanotubes is 5-10 μm, and the specific surface area is 800 m 2 / g.

[0067] This embodiment discloses a lithium battery positive electrode material. The pre...

Embodiment 2

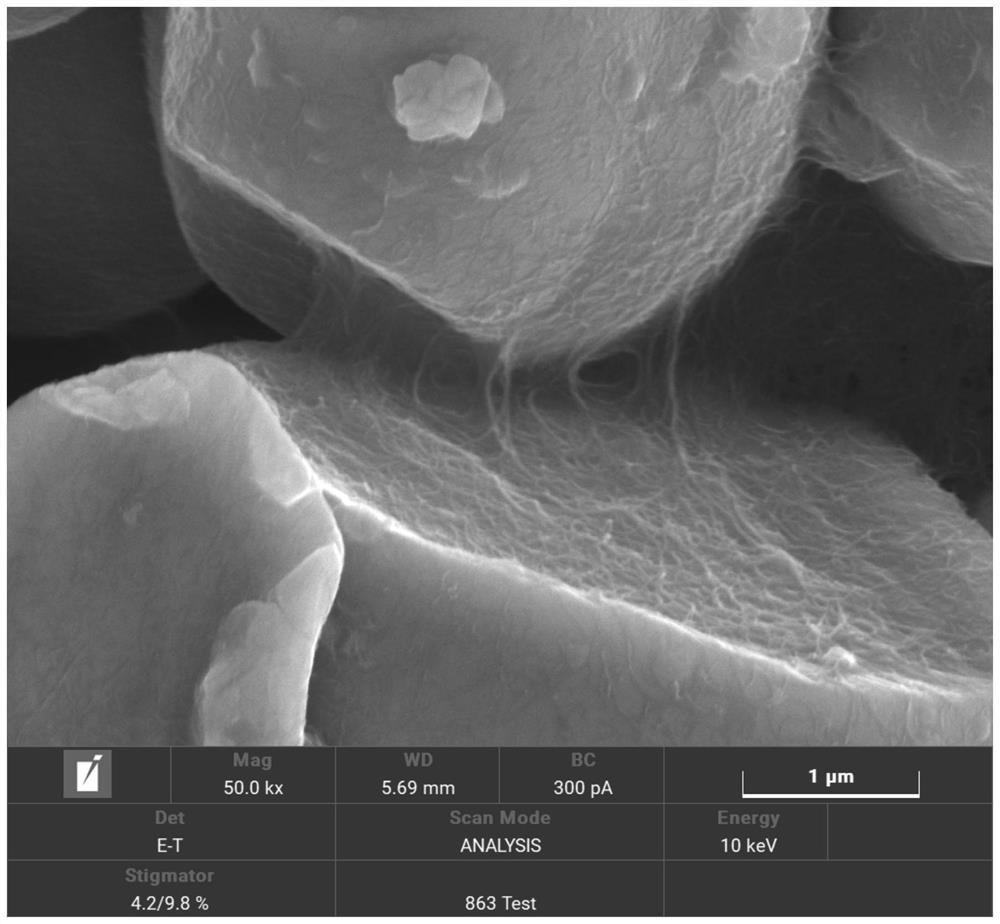

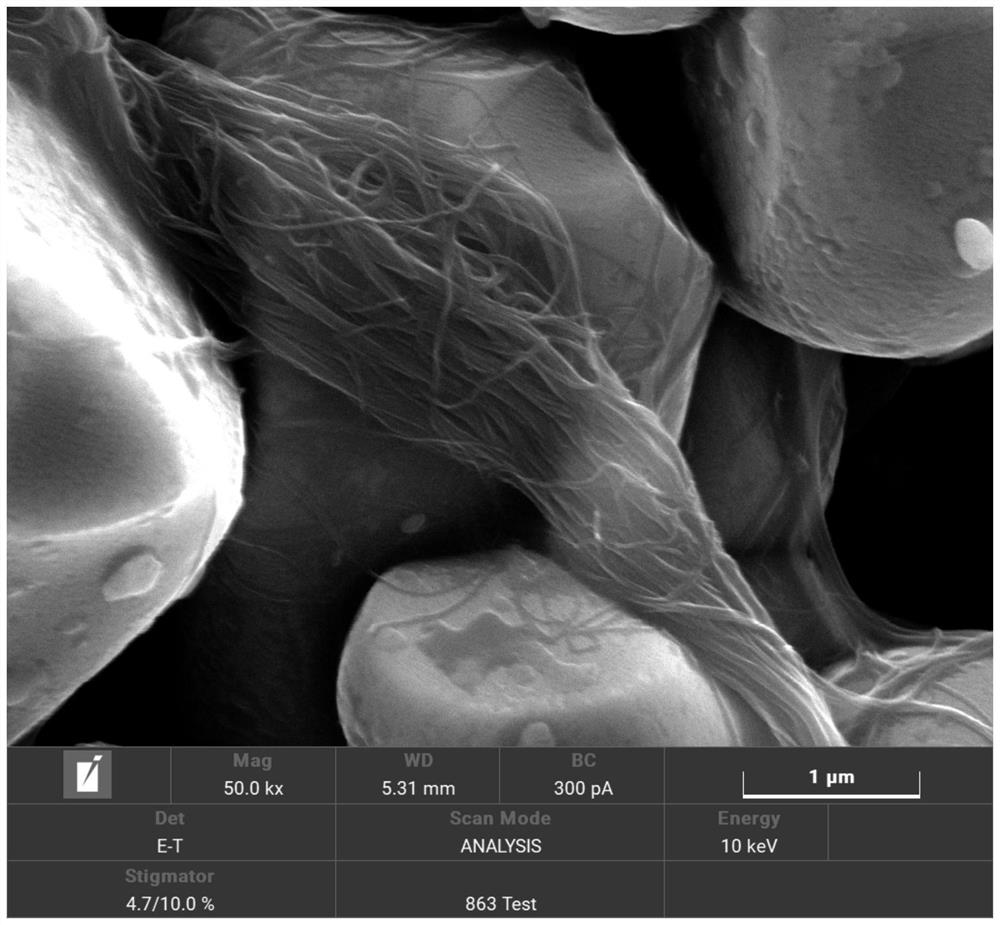

[0069] This embodiment discloses a lithium battery conductive agent, the preparation process of which includes: weighing 400 g of multi-walled carbon nanotubes and 1600 g of polyvinylidene fluoride (PVDF), mixing in a kneader for 30 minutes, taking out the mixed materials, Get a premix. The setting parameters of the twin-screw extruder are 30°C in the first zone and 220°C in the second to sixth zones. After the temperature of the machine rises to the set temperature, the premix is put into the feeding barrel of the twin-screw extruder, and the feed is extruded. After granulation, the granulated granules are dried and crushed to below 50 mesh to obtain a lithium battery conductive agent. Among them, the molecular weight of polyvinylidene fluoride is 1.2 million, the length of multi-walled carbon nanotubes is 5-10 μm, and the specific surface area is 400 m 2 / g.

[0070] This embodiment discloses a lithium battery positive electrode material. The preparation process includes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com