Motor stator connecting piece based on circumferential step-shaped circular ring

A motor stator, stepped technology, applied in the field of motor stator connectors, can solve problems such as affecting motor performance, and achieve the effects of less assembly difficulty, uniform force, and high bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

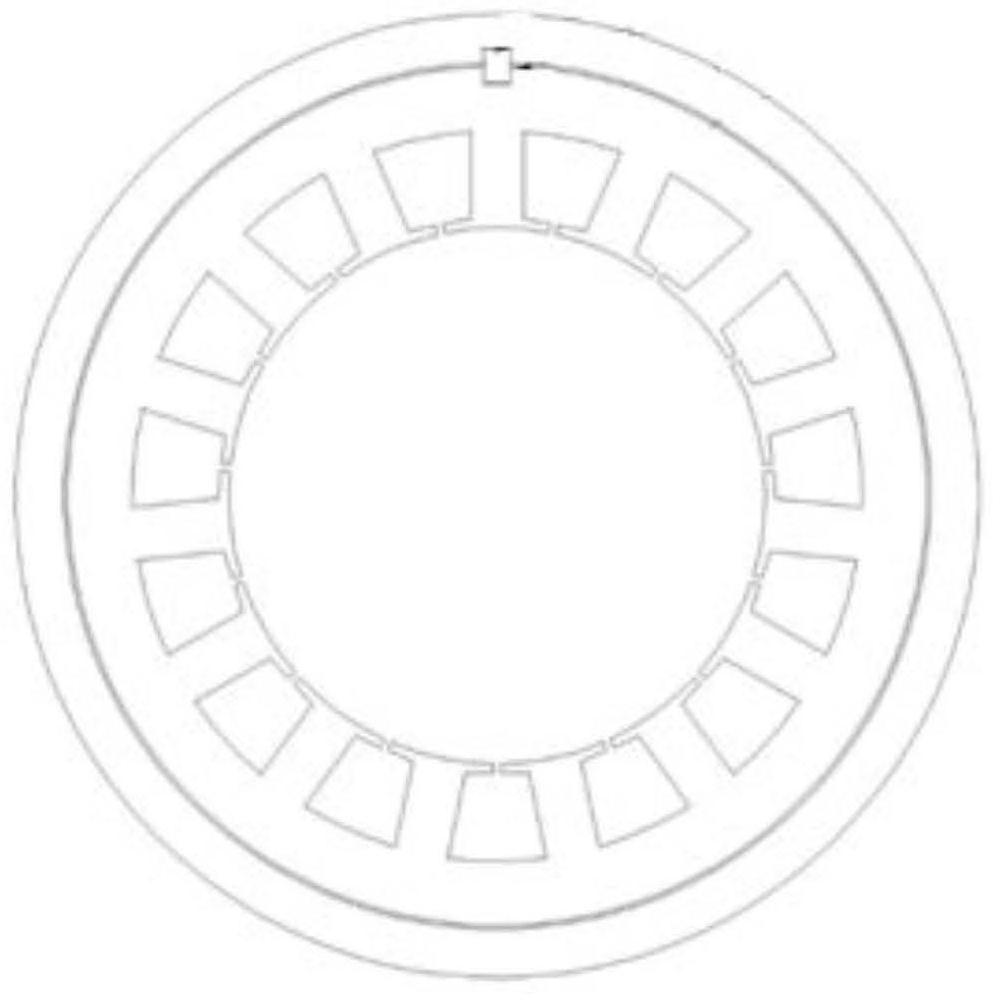

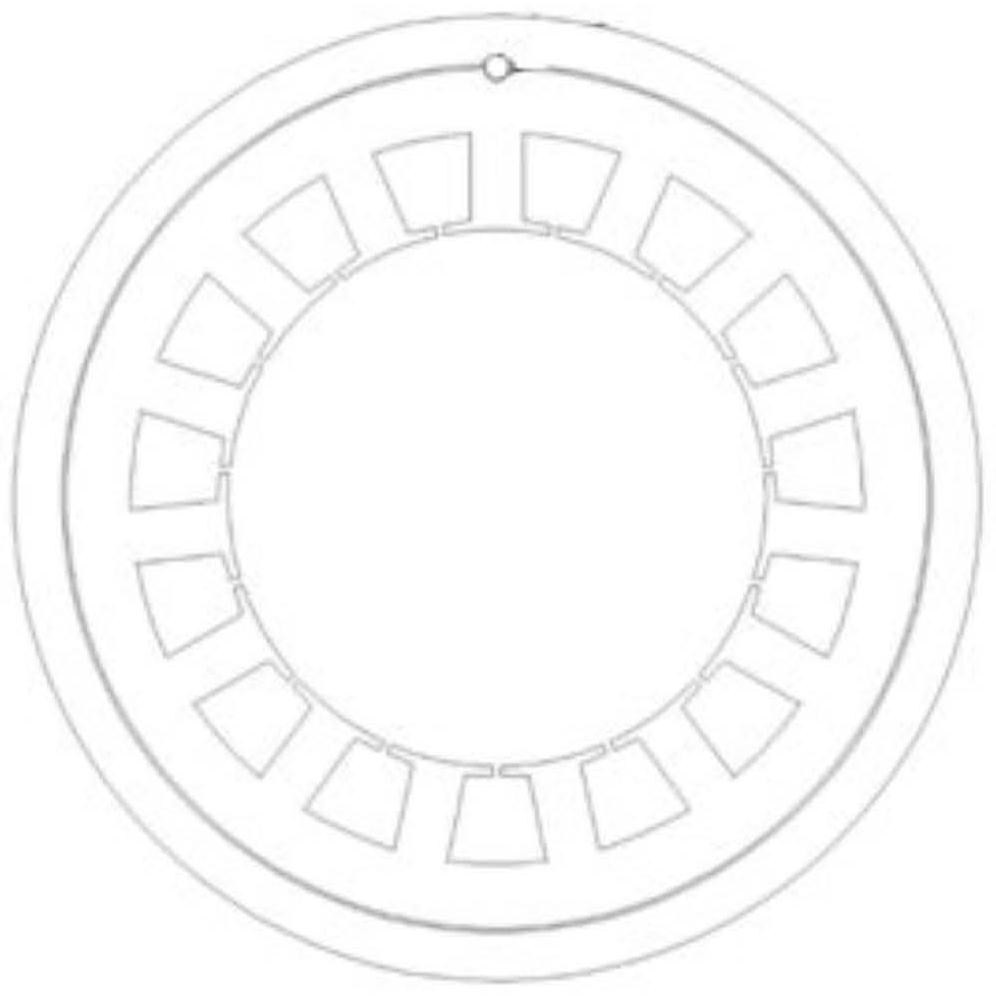

[0073] Specific embodiment one: the following combination Figure 3-Figure 8 Describing this embodiment, the motor stator connector based on the circumferential stepped ring described in this embodiment, the outer circle of the stator core 1 includes N steps, where N is an even number greater than or equal to 2, and the outer circle of the stator core 1 at the steps Different diameters, the stator core 1 is a radially symmetrical structure, the inner circle of the casing is a stepped shape that matches the outer circle of the stator core 1, and the inner diameter of the casing matches the outer diameter of the core;

[0074] When there is one axis of symmetry of the stator core (1), N=2, 4, 6, 8, ..., which is n times 2, and n is 1, 2, 3, ..., at this time, the stator core (1) The diameters of the outer circles correspond to 2, 3, 4, 5, ... species, namely n+1;

[0075] When there are two axes of symmetry of the stator core (1), N=4, 8, 12, 16, ..., which is n times 4, and n ...

specific Embodiment approach 2

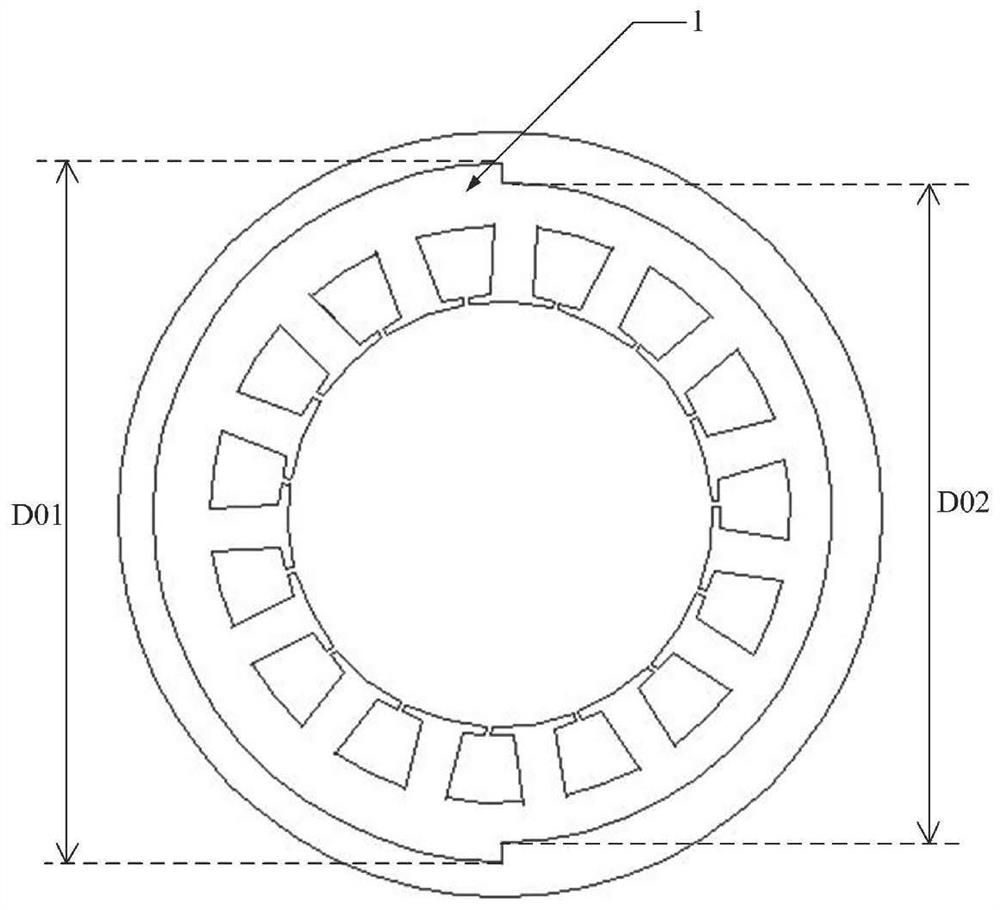

[0077] Specific embodiment two: the following combination Figure 8 Describing this embodiment, this embodiment further describes Embodiment 1. The stator core 1 is provided with key teeth 2 on the side of the outer circle with the largest diameter, and the inner circle of the casing is provided with key grooves matched with the key teeth 2 .

specific Embodiment approach 3

[0078] Specific embodiment three: the following combination image 3 This embodiment is described. This embodiment further describes Embodiment 1. When N is 2, the outer diameters of the stator core 1 are D01 and D02 respectively;

[0079] The left side of the first step is the outer circle of D01 diameter, the right side of the first step is the outer circle of D02 diameter,

[0080] The left side of the second step is the outer circle of D02 diameter, and the right side of the second step is the outer circle of D01 diameter.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com