Motor stator winding, stator, motor and vehicle

A motor stator and winding technology, applied to the shape/style/structure of windings, electric components, winding conductors, etc., can solve problems such as motor overheating, increased motor additional loss, winding branch asymmetry, etc., to facilitate assembly and batch production production, ease of mass production, and reduced complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

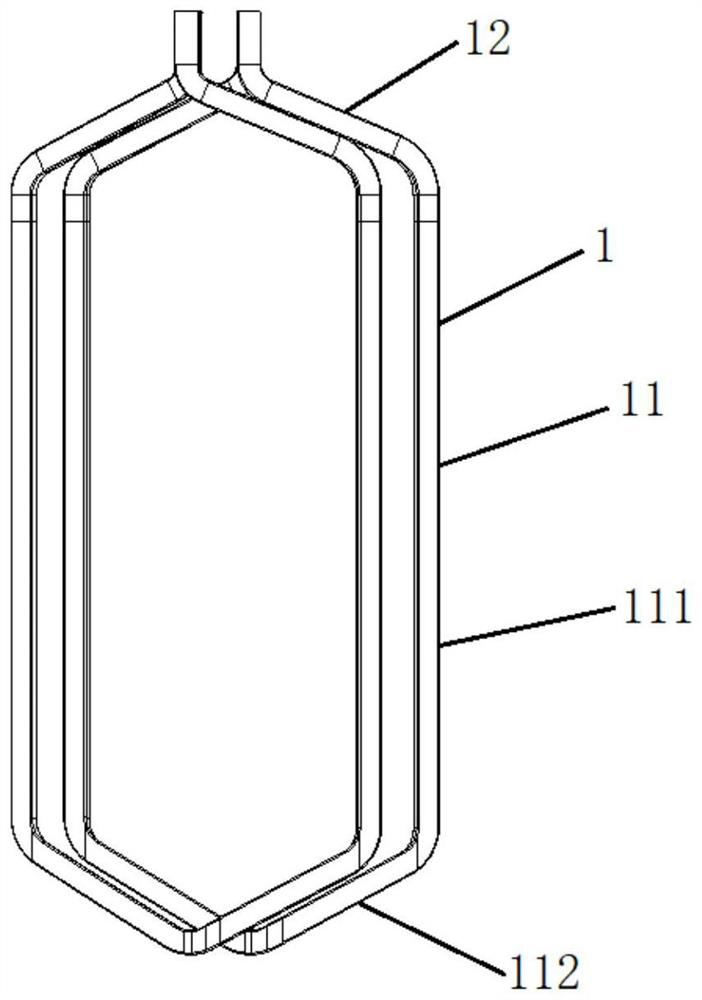

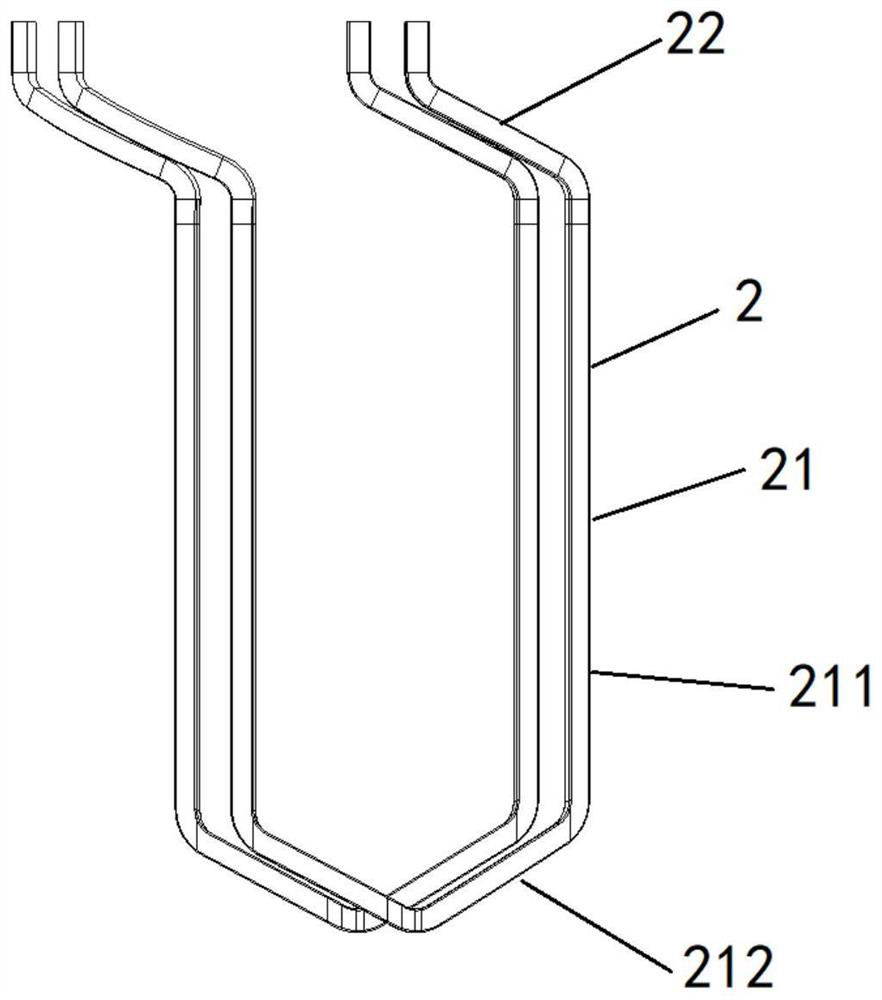

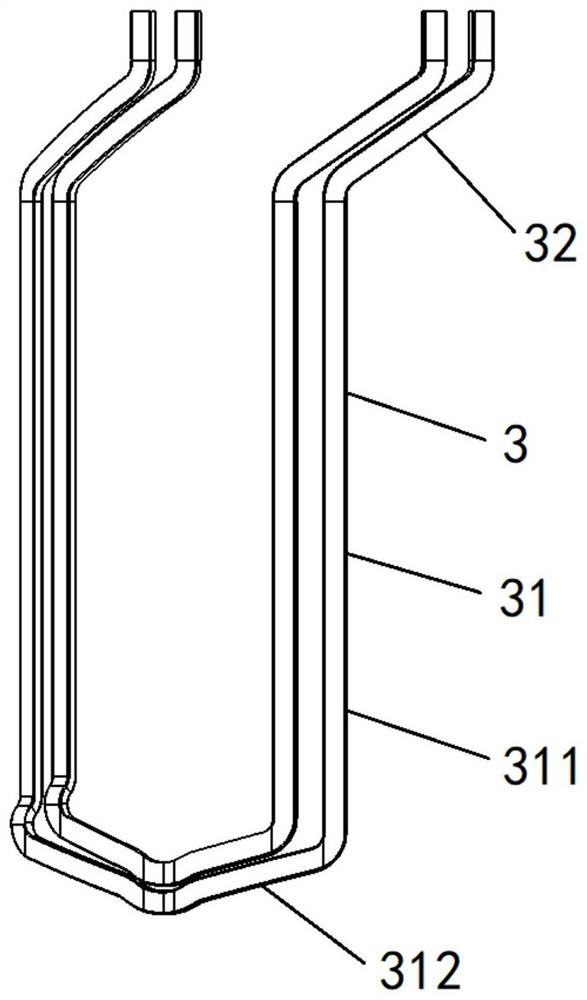

[0045] like Figure 1 to Figure 6 As shown, the stator winding of the motor in this embodiment includes three-phase phase windings. Each phase winding includes multiple groups of parallel winding branches, each group of winding branches includes two parallel branches, and each branch includes a plurality of coils arranged in sequence on the circumferential core slot 51 of the stator core 5 and connected in series with each other. .

[0046] Both branches include m coils with a span of y+1 and n coils with a span of y-1. The spans of other coils are all y, and both m and n are positive integers. In the two branches, the coil with the span y+1 and the coil with the span y-1 are arranged in the outermost layer of the slot of the core slot 51 (from the slot bottom to the last first layer in the slot direction). ), and a coil with a span of y+1 in one of the winding branches of each group and a coil with a span of y-1 in the other adjacent branch are arranged in adjacent core slo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com