Structured filler element with reduced material demand

A technology of structured packing and components, applied in chemical instruments and methods, chemical/physical processes, chemical/physical/physicochemical processes, etc., can solve problems such as low capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

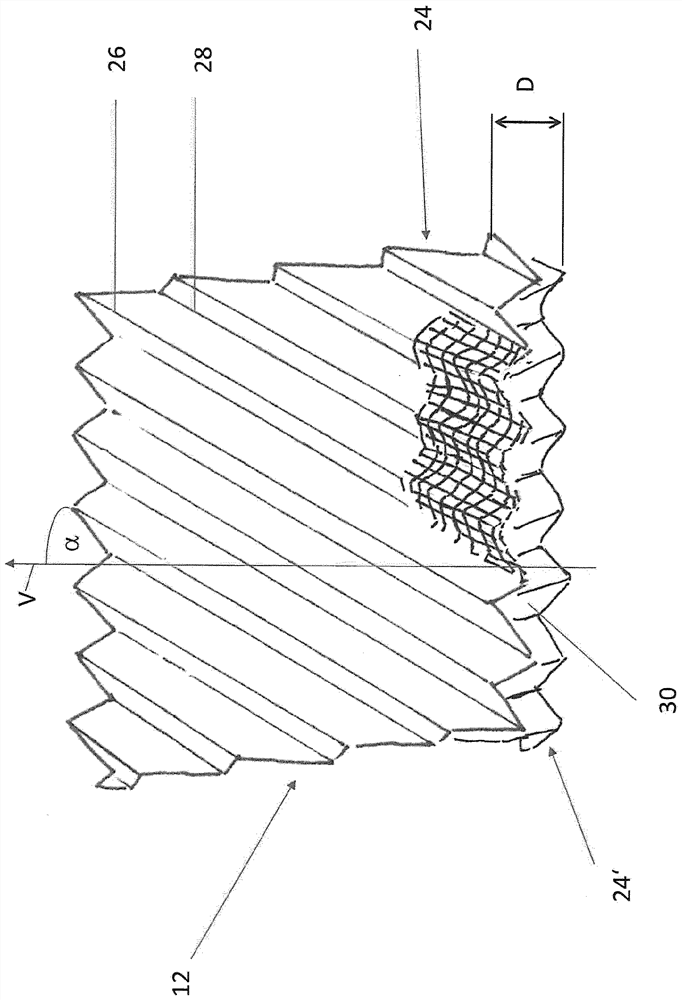

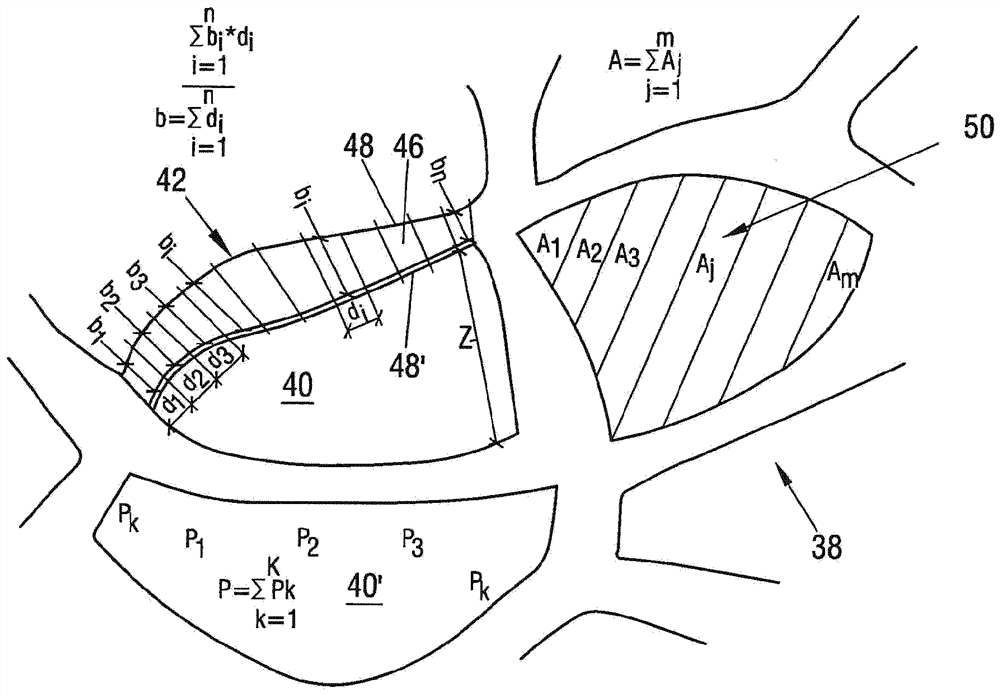

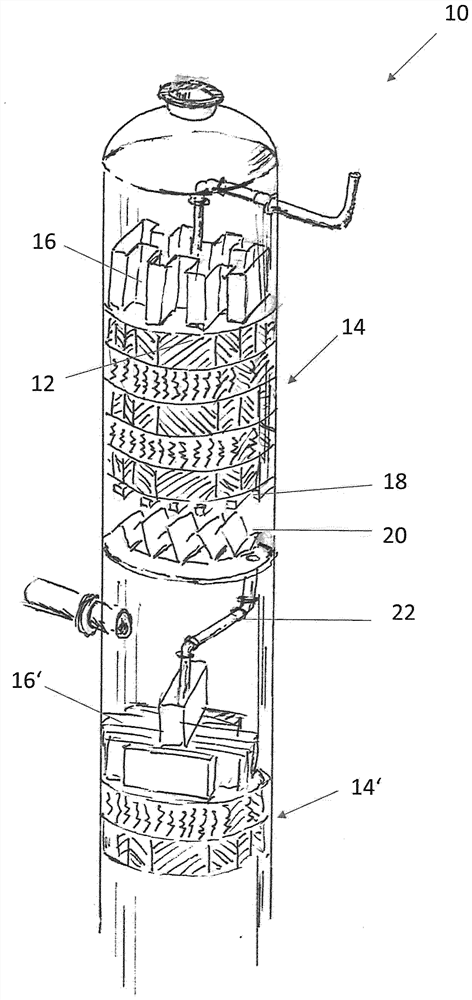

[0092] figure 1 A schematic side view of a mass transfer column 10, and more specifically a distillation column 10, according to one embodiment of the present invention is shown (the transparent interior of the figure is for illustrative purposes only). Again, for illustrative purposes, the grid structure of the layers is not shown in figure 1 , but only shown in Figure 6. Distillation column 10 includes a plurality of structured packing elements 12 arranged in two beds 14, 14'. Distributors 16, 16' are arranged above each of the two beds 14, 14' to distribute the liquid evenly across the cross-section of the beds, while leaving sufficient space for the vapor to rise through it. A grid-like holding device 18 and a collector 20 are arranged below each bed 14 , 14 ′, wherein the grid-like holding device 18 holds the bed 14 in place and the collector 20 collects the trickle down from the bed 14 . liquid while leaving enough open space in the collector for the vapor to r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com