Polishing pad, preparation method of polishing pad and manufacturing method of semiconductor device

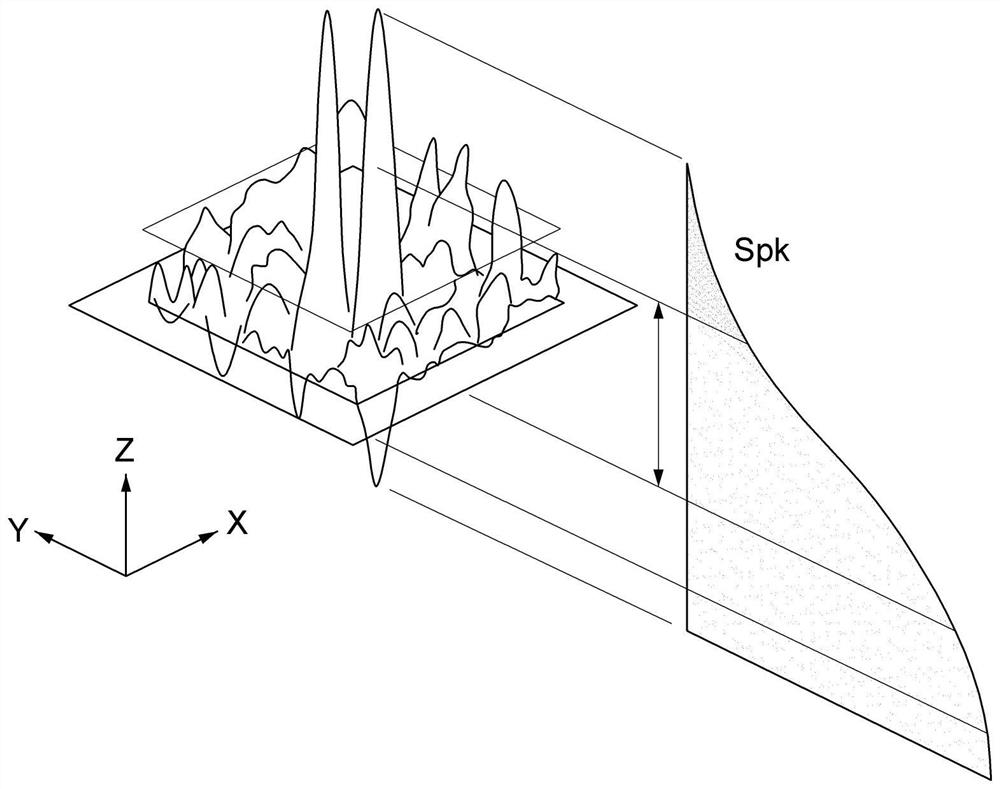

A polishing pad and semiconductor technology, applied in the field of polishing pads, can solve the problems of increasing dish-shaped depressions on the surface of semiconductor wafers, and achieve the effects of reducing the Spk reduction rate, increasing the area, and preventing defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

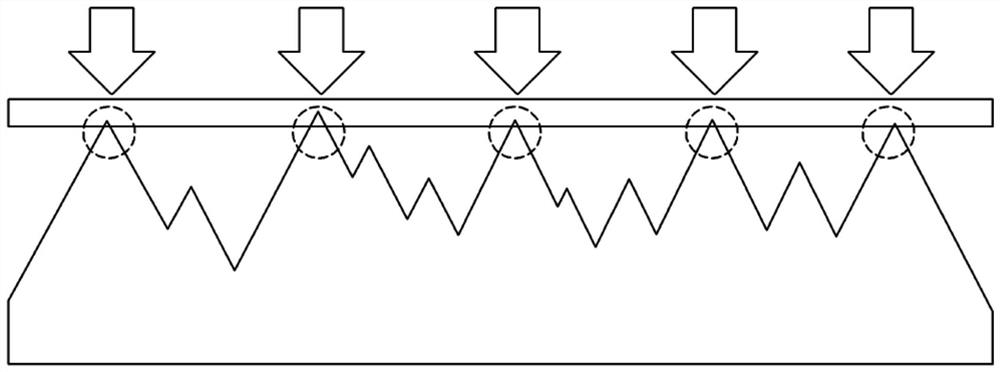

[0087] In the existing preparation of the polishing layer in the polishing pad, pores with irregular size and arrangement are formed by physical or chemical methods. According to the existing preparation method of the polishing layer, pores with various shapes and sizes are arranged in an irregularly dispersed form on the surface and inside of the polishing layer of the polymer material.

[0088] In the existing method of forming pores or pores in the polishing layer, the physical method is to mix minute substances in the forming substances of the polishing layer. In this case, the porous micro-substance should be thoroughly mixed with the polymer in the initial stage of preparation of the polishing layer.

[0089] However, in the physical method, it is difficult to sufficiently and uniformly mix the fine substances with the polymer in the initial stage, and the sizes of the fine substances also vary.

[0090] Generally, the average diameter of pores formed by physical method...

Embodiment 1

[0196] Preparation of polishing pads

[0197] By combining TDI, H 12 MDI, polytetramethylene ether glycol (Polytetramethylene ether glycol) and diethylene glycol (Diethylene glycol) were put into a four-necked flask and reacted at 80 °C for 3 hours to prepare prepolymers with an NCO% of 8 to 12%. thing.

[0198] To prepare the Top Pad, the prepolymer tank was filled with the prepared polymers and catalysts.

[0199] At this time, 0.002 parts by weight of a catalyst (which is triethylamine) was charged based on 100 parts by weight of the prepolymer. The curing agent tank (Tank) was filled with bis(4-amino-3-chlorophenyl)methane (bis(4-amino-3-chlorophenyl)methane, Ishihara Corporation). The unexpanded solid blowing agent (Akzonobel Corporation, 551DU40) was mixed with the prepolymer prior to filling into the prepolymer tank.

[0200] During casting, the equivalent of prepolymer and curing agent was adjusted to 1:1, spit out at a speed of 10kg / min, and injected with inert g...

Embodiment 2

[0203] By combining TDI, H 12 MDI, polytetramethylene ether glycol, and diethylene glycol were put into a four-necked flask, and then reacted at 80° C. for 3 hours to prepare a prepolymer having an NCO% of 8 to 12%.

[0204] To prepare the top mat, the prepolymer tank was filled with the prepared prepolymer and catalyst in a casting apparatus provided with prepolymer, curing agent, inert gas injection lines and liquid blowing agent injection lines.

[0205] At this time, 0.001 part by weight of a catalyst (which is triethylamine) was charged based on 100 parts by weight of the prepolymer. The curing agent tank was filled with bis(4-amino-3-chlorophenyl)methane (Ishihara Corporation). Unexpanded solid blowing agent (Akzonobel Corporation, 551DU40) was mixed with the prepolymer prior to filling into the prepolymer tank.

[0206] During casting, the equivalent of the prepolymer and the curing agent is adjusted to 1:1, spit out at a speed of 10kg / min, inject inert gas nitrogen a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com