Atomization oxygenation device for fishing

An oxygen-enhancing device, a technology for fishing, applied in the application, fish farming, animal husbandry and other directions, can solve the problems of pure oxygen waste, limitation of the effect of oxygen-enhancing measures, etc., to improve the utilization rate, increase the surface area of water droplets, increase the The effect of the dissolution of oxygen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

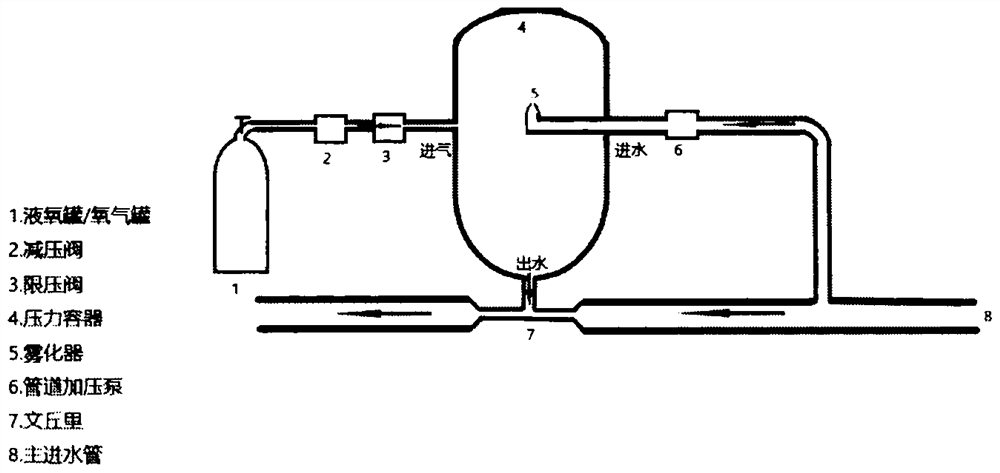

[0020] The following refer to the attached figure 1 , the specific embodiments of the present invention are described, and the present invention is further elaborated.

[0021] The atomized water in the device (4) comes from aquaculture water, and is connected to the water inlet pipe of the aquaculture pond by using a pipeline, and enters the device after being pressurized by the pipeline pump (6), and the vertically upward atomizer ( 5) Atomize the water in the pipeline into extremely fine water molecules.

[0022] The other nozzle of the device is connected to the oxygen tank or the liquid oxygen tank (1). The oxygen in the tank enters the device through the pressure reducing valve (2) and the pressure-stabilizing valve (3). The pressure-stabilizing valve provides a stable source of oxygen for the device. .

[0023] The extremely fine water molecules formed by atomization fully contact and dissolve oxygen in the container, gradually agglomerate and settle under the action ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com