Straightening system for improving plate shape of oriented steel finished product and control method of straightening system

A control method and technology for finished steel products, which are applied in the directions of cleaning methods using liquids, chemical instruments and methods, cleaning methods and utensils, etc., and can solve the imprinting defects of steel belts, foreign body nodules on the surface of straightening rollers, and stretching and leveling effects. limited and other problems, to achieve the effect of improving the ability of stable production, realizing closed-loop automatic control, convenient monitoring and cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to make the objectives, technical solutions and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings and embodiments. It should be understood that the specific embodiments described herein are only used to explain the present invention, but not to limit the present invention. In addition, the technical features involved in the various embodiments of the present invention described below can be combined with each other as long as there is no conflict with each other.

[0035] It should be pointed out that, according to the needs of implementation, the various steps / components described in this application may be split into more steps / components, or two or more steps / components or partial operations of steps / components may be combined into new steps / components to achieve the purpose of the present invention.

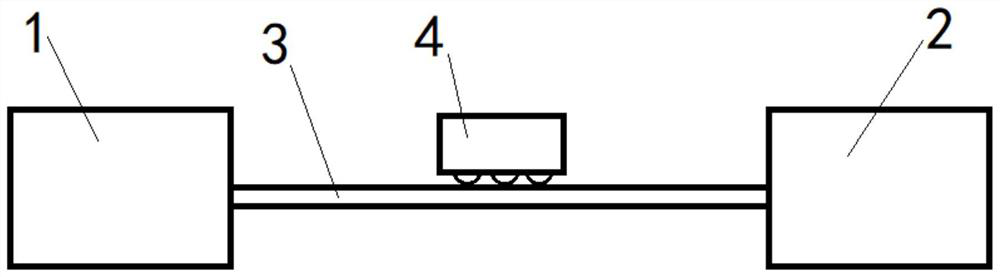

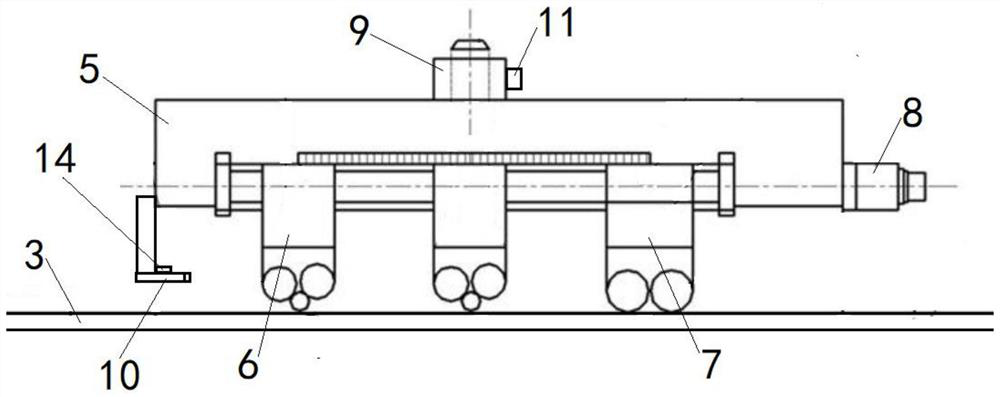

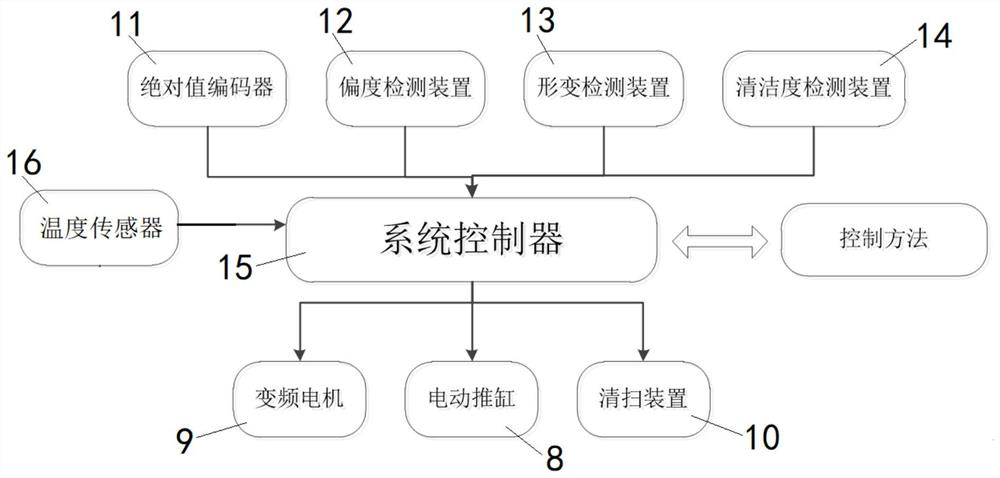

[0036] 1. A straightening system for improving the sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com