Machine tool for machining spindle hole of five-axis linkage low-temperature motor

A technology of five-axis linkage and processing machine tools, which is applied in the direction of metal processing machinery parts, metal processing equipment, manufacturing tools, etc., can solve the problems of time-consuming and labor-intensive use, insufficient linkage, etc., achieve convenient use, ensure drilling effect, and improve utilization rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

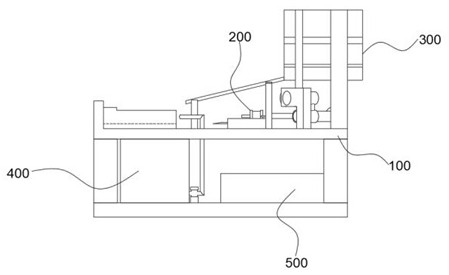

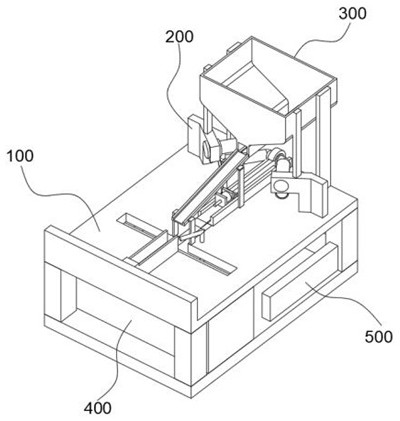

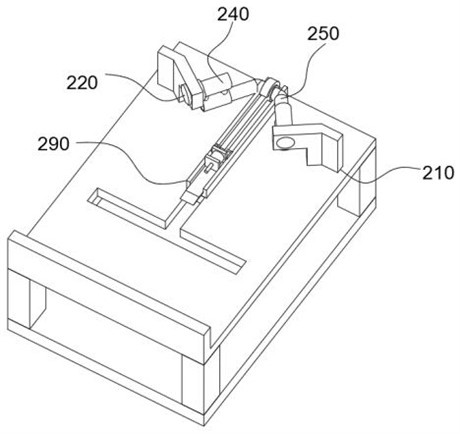

[0044] combine Figure 1-Figure 8 As shown, the present invention provides a five-axis linkage low-temperature motor spindle shaft hole processing machine tool, including a processing table 100, and the processing table 100 is provided with a processing module 200, a feeding module 300 and a flushing module 400. The processing module 200 includes two support plates 210 connected to the top of the processing table 100, a motor 220 connected to the support plate 210 close to the right side of the processing table 100, and movably connected to the support plate 210 away from the right side of the processing table 100 The cylinder 230, the two rotating members 240 connected with the motor 220 and the cylinder 230, the connecting shaft 250 movably connected between the two rotating members 240, the connecting shaft 250 movably sleeved on the outside of the connecting shaft 250 The connecting rod 260, the drilling machine 270 movably installed at the front end of the connecting rod ...

Embodiment 2

[0053] combine figure 1 , figure 2 and Figure 8 As shown, on the basis of Embodiment 1, a plurality of enclosure plates 500 are installed on the table body 410, and the plurality of enclosure plates 500 are located on one side of the water frame 420, and the inner side of the plurality of enclosure plates 500 is connected to the table. A storage area is formed between the top of the body 410 , and the enclosure plate 500 is arranged to prevent the motor shaft falling from the T-shaped opening from rolling out of the table body 410 .

Embodiment 3

[0055] combine figure 1 , figure 2 and Image 6 As shown, in the above embodiment, auxiliary support plates are installed on both sides of the material frame 310 , and the two auxiliary support plates are respectively connected with the tops of the two support plates 210 , and the auxiliary support plates improve the stability of the material frame 310 , so that the structure of the material frame 310 is more stable.

[0056] The working principle and use process of the present invention: in the initial state, a plurality of motor shafts to be drilled are placed in the material frame 310, and it is stipulated that the diameter of the motor shaft is equal to the width of the upper half of the discharge port 320, and the upper half of the discharge port 320 The width of the part is larger than the lower half, so the motor shaft cannot fall freely, and then the width of the lower part of the discharge port 320 is equal to the width of the curved rubber plate 330, so when the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com